Method for preparing antimony by in-situ reduction of antimonous oxide with eutectic solvent

The technology of antimony trioxide and deep eutectic solvent is applied in the field of non-ferrous metal metallurgy, which can solve the problems of high production temperature, long time and complicated equipment, and achieve the effects of low electrolytic reduction temperature, short time and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The method for preparing antimony by in-situ reduction of antimony trioxide in the deep eutectic solvent, the specific steps are as follows:

[0016] (1) Under an inert atmosphere, mix the quaternary ammonium salt and the polyol according to the molar ratio of 1:2, and mix them uniformly at a temperature of 90°C (constant temperature oil bath) to prepare a deep eutectic solvent; the quaternary ammonium salt is chlorine choline, polyhydric alcohol is ethylene glycol;

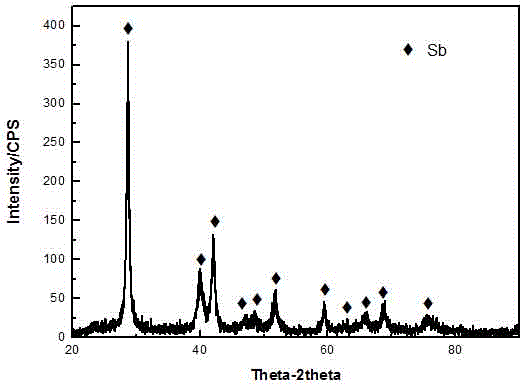

[0017] (2) Use the graphite crucible as the cathode and the electrolytic cell, place 0.5g of antimony trioxide powder at the bottom of the graphite crucible, use the 20ml deep eutectic solvent obtained in step (1) as the electrolyte, and insert the graphite into the electrolyte However, it cannot touch the antimony trioxide powder at the bottom. It is electrolyzed for 3 hours at an electrolysis temperature of 80°C and a cell voltage of 3V. Finally, the bottom powder of the cathode graphite crucible is take...

Embodiment 2

[0019] The method for preparing antimony by in-situ reduction of antimony trioxide in the deep eutectic solvent, the specific steps are as follows:

[0020] (1) Under an inert atmosphere, mix the quaternary ammonium salt and the polyol according to the molar ratio of 1:3, and mix them uniformly at a temperature of 70°C (constant temperature oil bath) to prepare a deep eutectic solvent; the quaternary ammonium salt is chlorine choline, polyhydric alcohol is propylene glycol;

[0021] (2) Use the graphite crucible as the cathode and the electrolytic cell, place 0.5g of antimony trioxide powder at the bottom of the graphite crucible, use the 20ml deep eutectic solvent obtained in step (1) as the electrolyte, and insert the graphite into the electrolyte However, it cannot touch the antimony trioxide powder at the bottom. It is electrolyzed for 6 hours at an electrolysis temperature of 90°C and a cell voltage of 3.2V. Finally, the bottom powder of the cathode graphite crucible is t...

Embodiment 3

[0023] The method for preparing antimony by in-situ reduction of antimony trioxide in the deep eutectic solvent, the specific steps are as follows:

[0024] (1) Under an inert atmosphere, mix quaternary ammonium salts and polyols at a molar ratio of 2:3, and mix them uniformly at a temperature of 73°C (constant temperature oil bath) to prepare a deep eutectic solvent; the quaternary ammonium salts are tetra Methyl ammonium chloride, polyhydric alcohol is propylene glycol;

[0025] (2) Use the graphite crucible as the cathode and the electrolytic cell, place 0.5g of antimony trioxide powder at the bottom of the graphite crucible, use the 20ml deep eutectic solvent obtained in step (1) as the electrolyte, and insert the graphite into the electrolyte However, the antimony trioxide powder that cannot touch the bottom is electrolyzed for 5.5 hours at an electrolysis temperature of 70°C and a cell voltage of 2.8V. Finally, the powder at the bottom of the cathode graphite crucible is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com