Fabric rust remover

A rust remover and textile technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of rust remover pollution, etc., and achieve the effect of low cost, good rust removal effect, and excellent rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

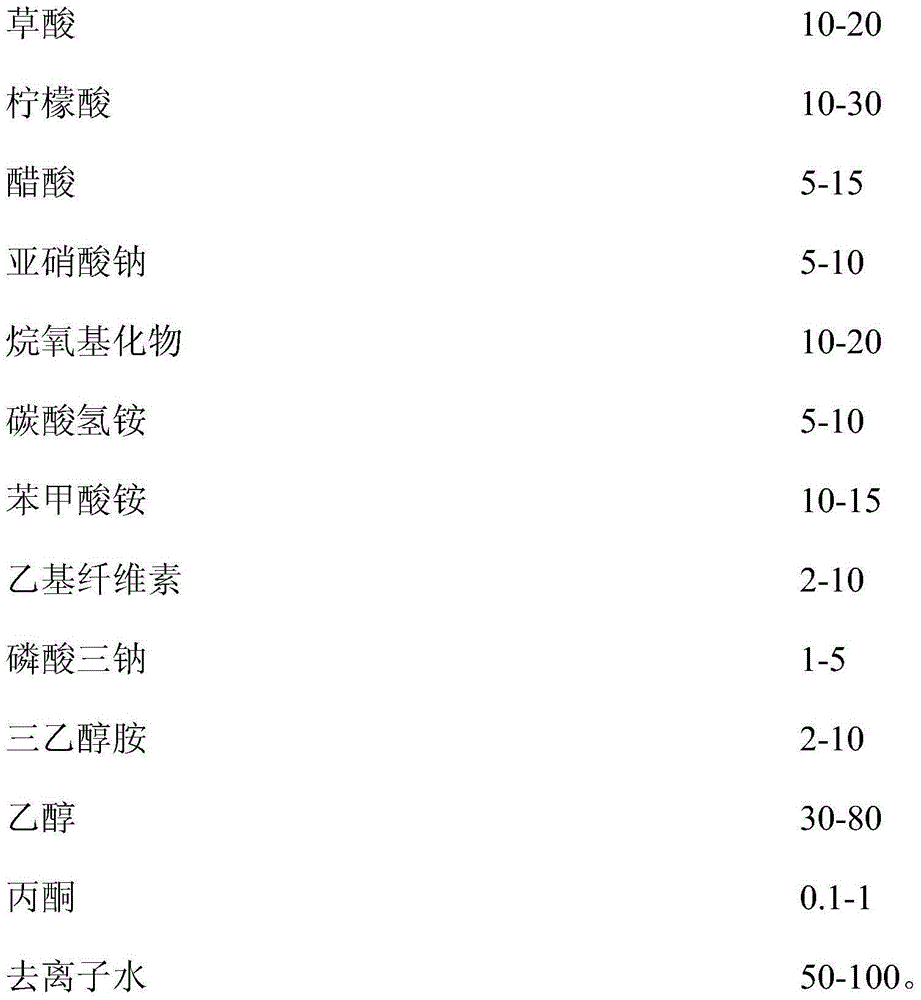

[0032] A textile rust remover, said rust remover comprises the following components in parts by weight:

[0033]

[0034] Wherein, the alkoxylate is a mixture of propylene oxide and butylene oxide.

[0035] The preparation method of fabric derusting agent in the present embodiment, comprises the steps:

[0036] (1) Mix the ethyl cellulose, ethanol and acetone in the above parts by mass, stir and mix evenly to obtain the component A solution for subsequent use;

[0037] (2) Mix the oxalic acid, citric acid, and acetic acid of the above-mentioned parts by mass, add the deionized water of the above-mentioned parts by mass, after stirring and mixing uniformly, add the trisodium phosphate, triethanolamine, bicarbonate of the above-mentioned parts by mass Ammonium and ammonium benzoate are stirred and mixed evenly to obtain component B solution for subsequent use;

[0038] (3) Mix other components and stir evenly to obtain component C solution for subsequent use;

[0039] (4) ...

Embodiment 2

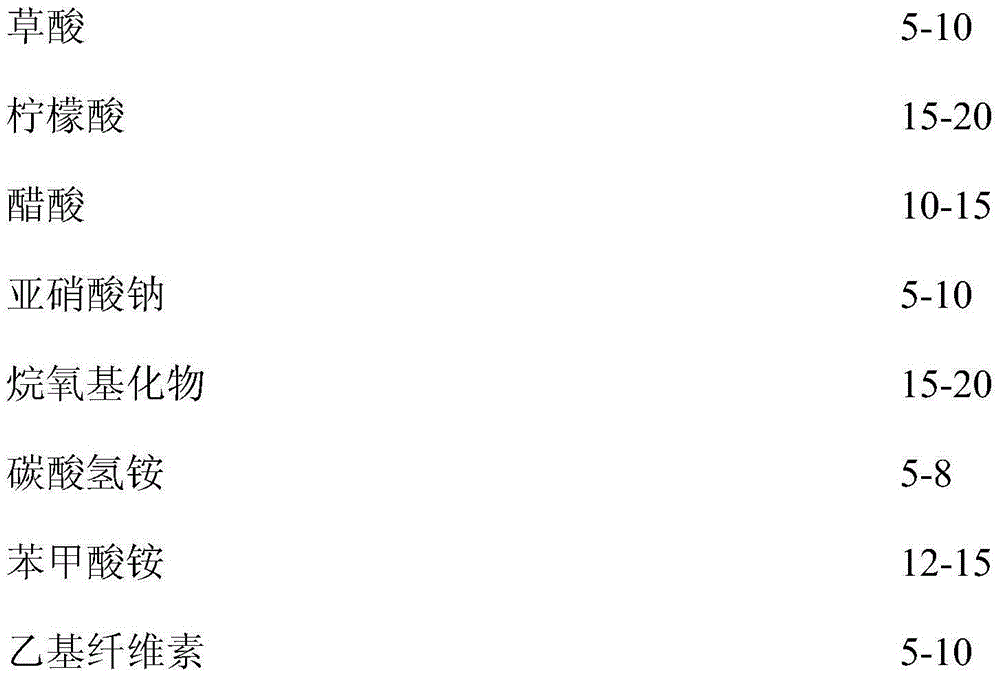

[0041] A textile rust remover, said rust remover comprises the following components in parts by weight:

[0042]

[0043] The preparation method of the textile rust remover is the same as in Example 1.

Embodiment 3

[0045] A textile rust remover, said rust remover comprises the following components in parts by weight:

[0046]

[0047] Wherein, the alkoxylate oxidizes cyclohexene.

[0048] The preparation method of the textile rust remover is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com