Surface coated particles and use of same

A surface coating and particle technology, applied in the pretreatment surface, the device and application of coating liquid on the surface, etc., can solve the problems of uneven white, high specific gravity, high viscosity, etc., and achieve excellent dispersibility and less coarse particles. , Excellent effect of hard caking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0101] Hereinafter, the surface-coated particle and its manufacturing method in the present embodiment will be described in order. In addition, "~" means from above to below unless otherwise specified.

[0102]

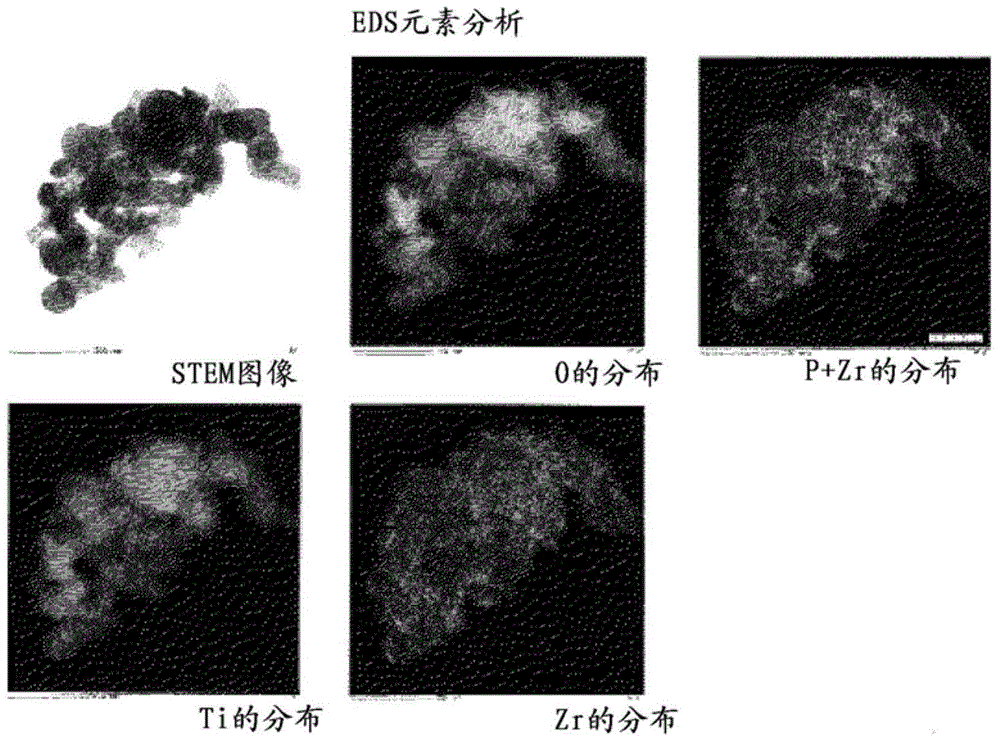

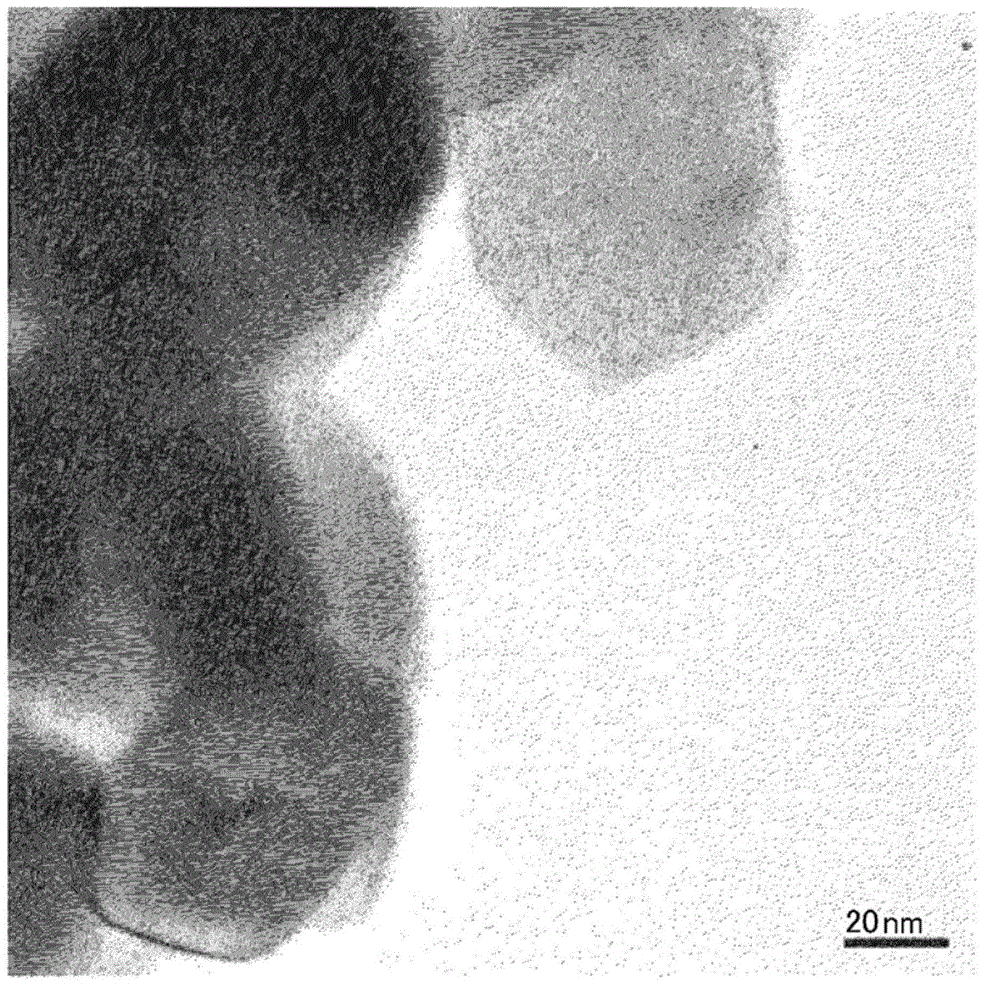

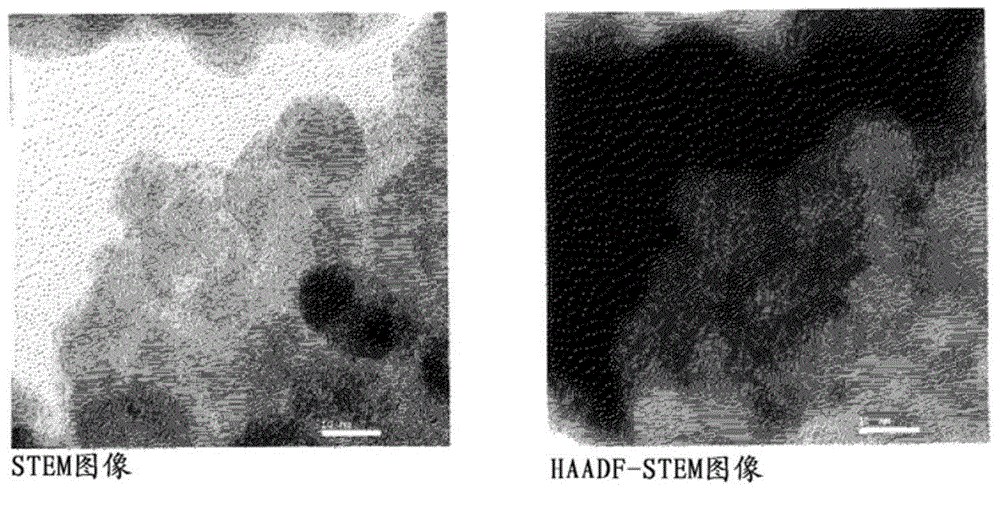

[0103] The surface-coated particles according to this embodiment include titanium dioxide particles and a coating film covering the titanium dioxide particles, and the surface-coated particles contain (a) phosphorus element or sulfur element and (b) elements selected from Groups 2 to 12 of the Periodic Table of Elements (but Excluding at least one element of titanium element), when the concentration of titanium element in the above-mentioned surface-coated particles is 100 atom%, the concentration of the above-mentioned (a) element is 2 atom% or more, and the above-mentioned (b) element is relative to the above-mentioned ( a) The atomic ratio (b) / (a) of the element exceeds 0.5.

[0104] In addition, the surface-coated particles of the present embodiment can be obta...

no. 2 Embodiment approach >

[0189] According to this embodiment, there is provided a particle containing titanium dioxide particles and at least one element selected from Group 2 to Group 12 elements of the periodic table (but excluding titanium), the specific surface area ( A BET(H2O) ) and the specific surface area (ABET(N2) ) ratio (A BET(H2O) / A BET(N2) ) is 1.0 or more.

[0190] In Patent Document 1, the aqueous dispersibility of titanium dioxide particles is improved by dispersing titanium dioxide particles in the presence of an organic polymer dispersant, but high concentration and low viscosity cannot be achieved.

[0191] In addition, in Patent Documents 2 to 3, whiteness and light scattering efficiency are maintained by surface coating, but there is no description of improvement in water dispersibility of titanium dioxide particles.

[0192] Patent Document 6 also does not describe improvement in water dispersibility of titanium dioxide particles.

[0193] In order to solve the above-mentio...

no. 3 Embodiment approach >

[0291] The present embodiment provides a pigment for water-based ink comprising titanium dioxide particles and a coating film covering the titanium dioxide particles, wherein the pigment for water-based ink contains (a) phosphorus element and (b) an , hafnium, magnesium and barium at least one element, the concentration of the titanium element in the above-mentioned water-based ink pigment is set as x (atom%), the concentration of the above-mentioned (a) element is set as y (atom%), and When the concentration of the above-mentioned (b) element is set to z (atom%), the above-mentioned x, y, and z are surrounded by a quadrilateral with the following points A, B, C, and D as vertices in the triangular diagram (x, y, z) in the region (including online).

[0292] A (91, 3, 6)

[0293] B(84, 2, 14)

[0294] C(79,6,15)

[0295] D (79, 9, 12)

[0296] The pigment for water-based ink of this embodiment is excellent in water dispersibility. In addition, when the pigment for water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com