Wet smelting method of nickel oxide ore

A smelting method and nickel oxide technology, applied in the direction of improving process efficiency, etc., can solve problems such as increased smelting costs, fluctuations in organic component content, increased losses, etc., and achieve the effect of suppressing the amount of sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

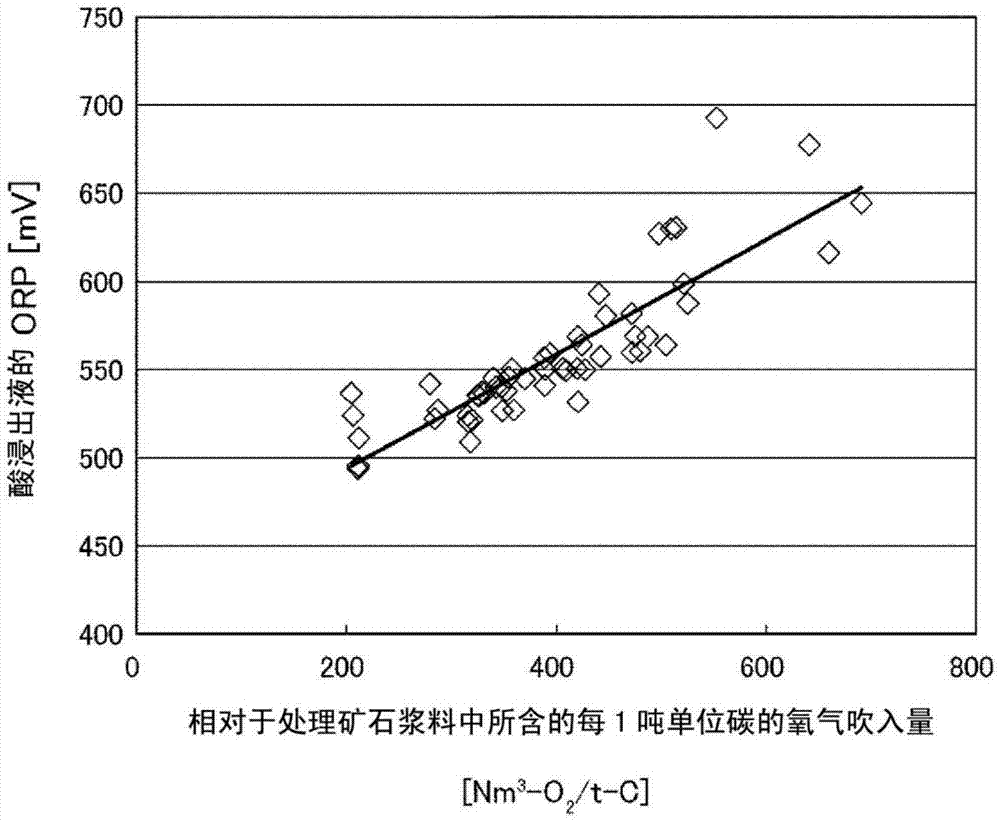

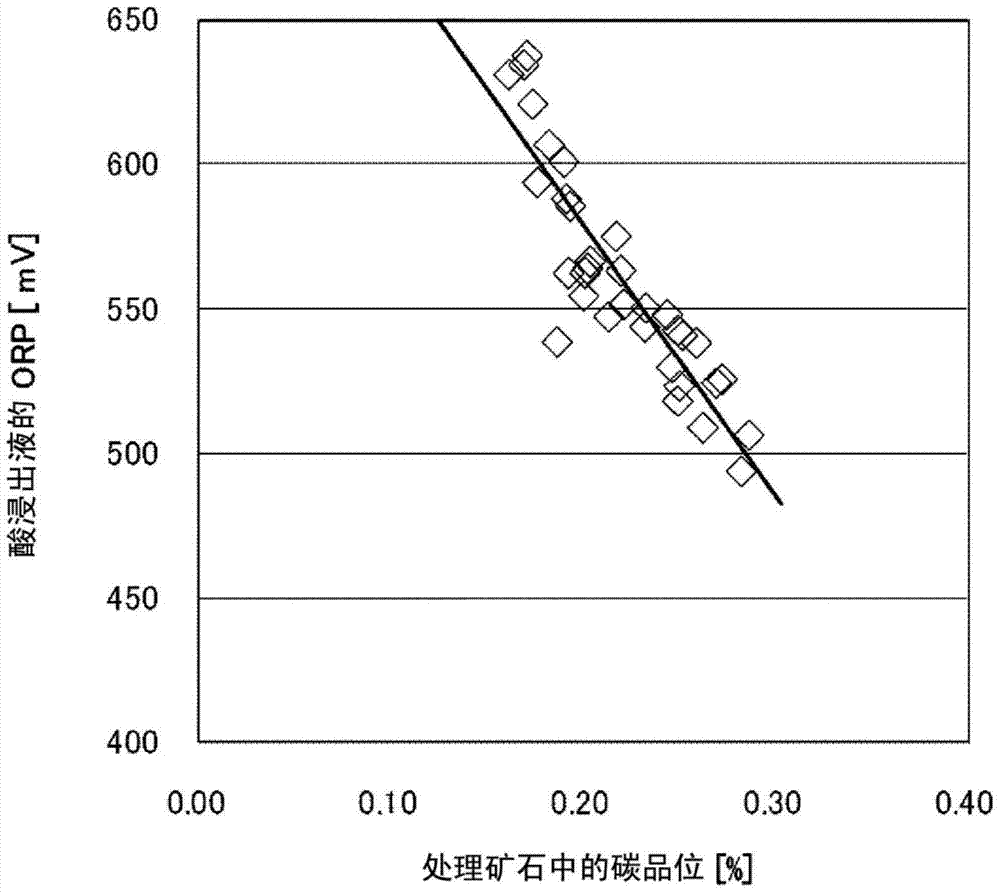

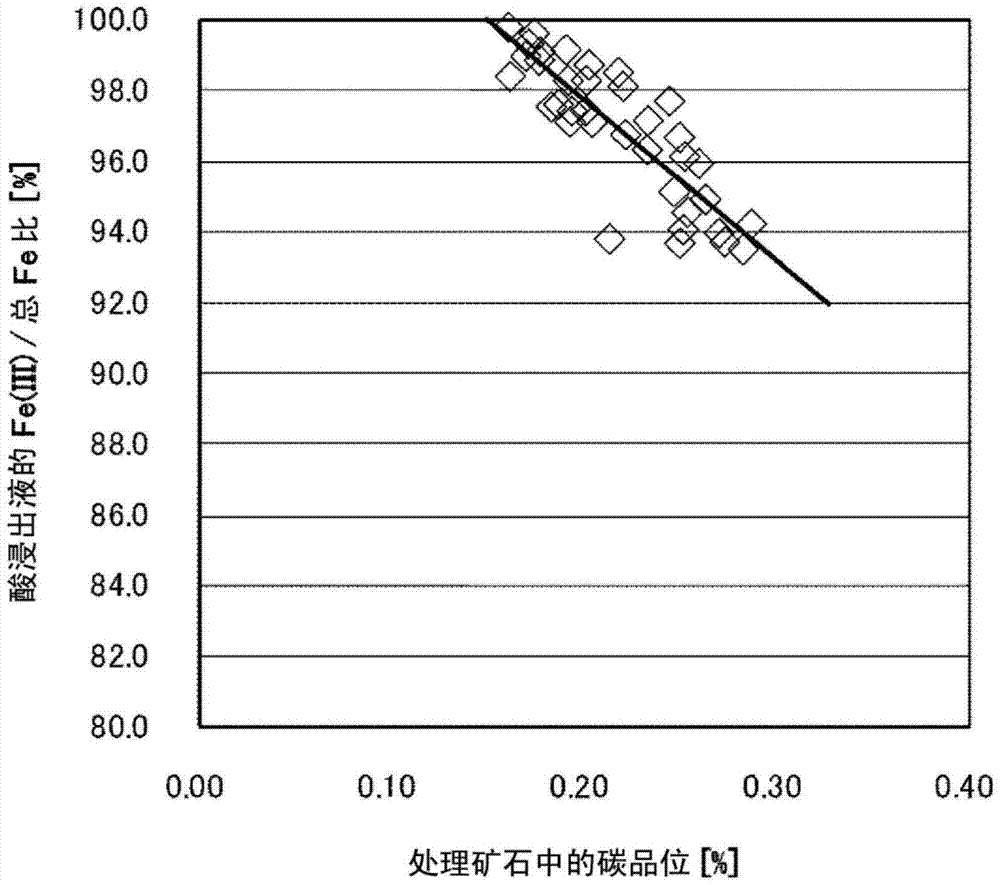

[0095] Example 1 is operated in the following manner: the carbon (C) grade in the solid content is 0.22% by weight, and for high-pressure air and high-pressure oxygen of about 5MPaG, the oxygen purity is adjusted to 46.6%, so as to correspond to 1 ton of carbon The amount is 426 [Nm 3 -O 2 / t-C] the oxygen blowing amount is blown in, and the oxygen partial pressure in the container is adjusted to 277kPaG. In addition, it operated while blowing high-pressure steam of about 5 MPaG, and maintaining the temperature of 245 degreeC, stirring.

[0096] As a result, the ORP (based on Ag / AgCl) of the obtained leaching slurry was properly maintained at 559mV, and the amount of sulfuric acid per 1 ton of dry ore was 226 [kg-H 2 SO 4 / t-dry-solids].

Embodiment 2

[0098] In Example 2, the operation was carried out in the following manner: the carbon (C) grade in the solid content was 0.23% by weight, and the oxygen purity was adjusted to 47.8% for high-pressure air and high-pressure oxygen of about 5MPaG, so as to correspond to each 1 ton of carbon is 317[Nm 3 -O 2 / t-C] the oxygen blowing amount is blown in, and the oxygen partial pressure in the container is adjusted to 277kPaG. In addition, it operated while blowing high-pressure steam of about 5 MPaG, and maintaining the temperature of 245 degreeC, stirring.

[0099] As a result, the ORP (based on Ag / AgCl) of the obtained leaching slurry was properly maintained at 518mV, and the amount of sulfuric acid per 1 ton of dry ore was 219 [kg-H 2 SO 4 / t-dry-solids].

Embodiment 3

[0101] In Example 3, the operation was carried out in the following manner: the carbon (C) grade in the solid content was 0.24% by weight, and the oxygen purity was adjusted to 54.7% for high-pressure air and high-pressure oxygen of about 5MPaG, so as to correspond to each 1 ton of carbon is 412[Nm 3 -O 2 / t-C] the oxygen blowing amount is blown in, and the oxygen partial pressure in the container is adjusted to 325kPaG. In addition, it operated while blowing high-pressure steam of about 5 MPaG, and maintaining the temperature of 245 degreeC, stirring.

[0102] As a result, the ORP (based on the Ag / AgCl electrode) of the obtained leaching slurry was properly maintained at 528mV, and the amount of sulfuric acid per 1 ton of dry ore was 232 [kg-H 2 SO 4 / t-dry-solids].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com