Cavity core-shell structured TiO2/WO3 composite photocatalyst and preparation method therefor and application thereof

A core-shell structure and catalyst technology, which is applied in the field of preparing hollow core-shell structure TiO2/WO3 composite photocatalysts, can solve the problems of complicated procedures and complicated methods, and achieve strong photocatalytic oxidation, high separation efficiency and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

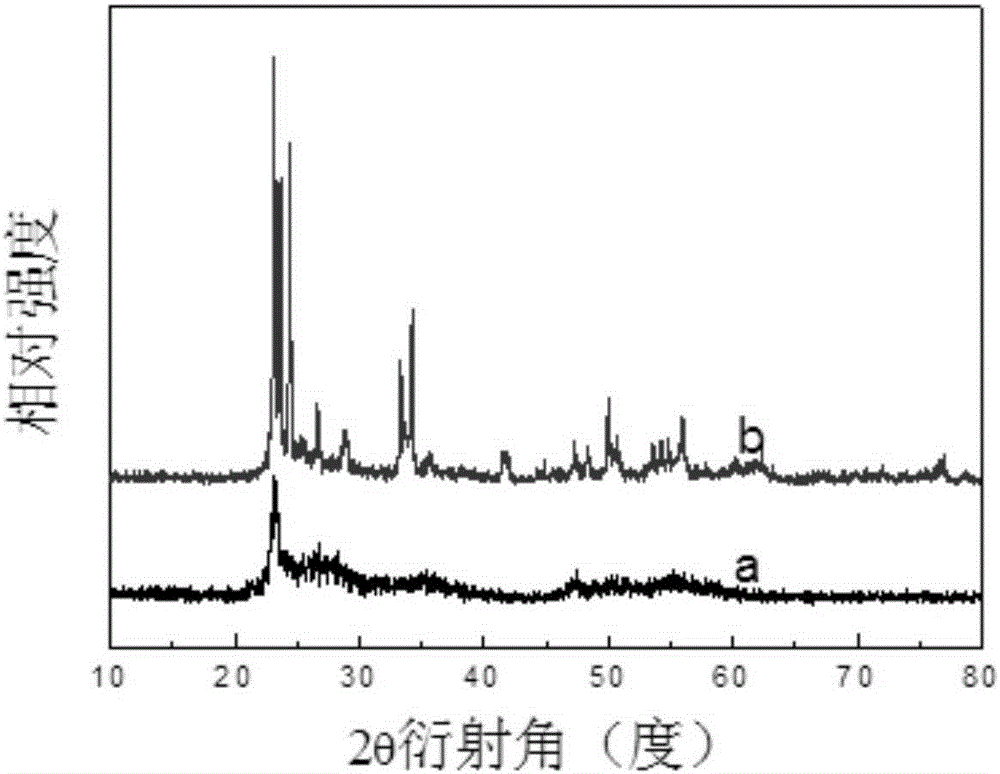

[0024] Under water bath conditions, 140uL (1.27mmol) of titanium tetrachloride was added to 20mL of tert-butanol and 20mL of ethylene glycol, and vigorously stirred until titanium tetrachloride was completely dissolved to form a transparent solution. 1.0g of tungsten hexachloride (2.52 mmol) was dissolved in 50mL of absolute ethanol, and then the above mixed solution was transferred to a 100mL polytetrafluoroethylene kettle (accounting for about 90% of the kettle volume), kept at 160°C for 48h, cooled to room temperature naturally, and centrifuged to prepare Hollow core-shell structure TiO 2 / WO 3 composite photocatalyst.

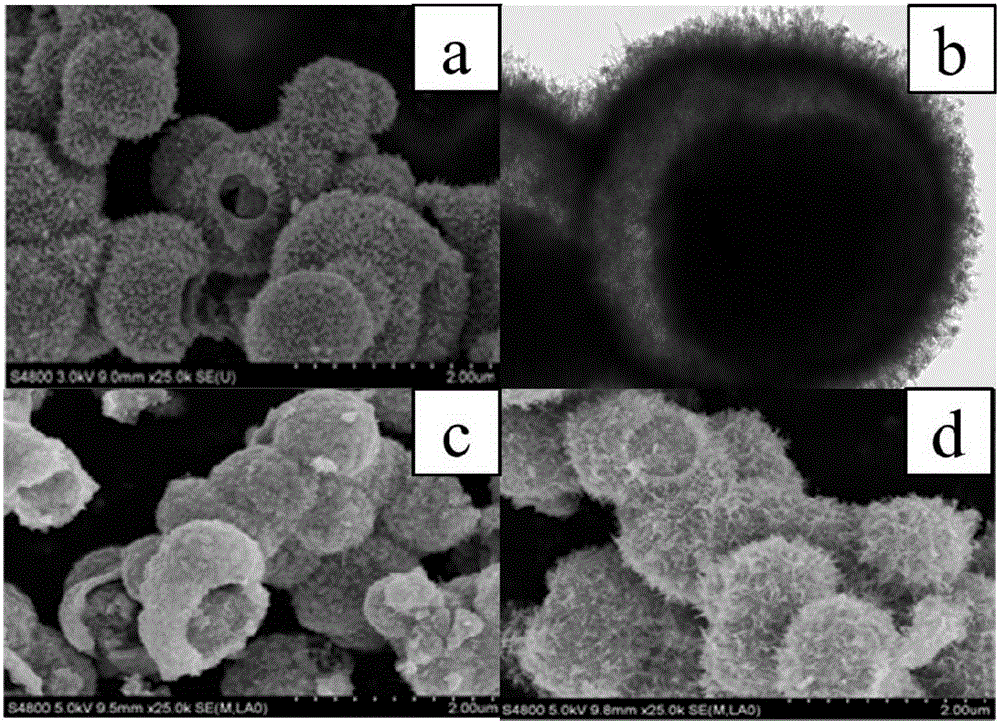

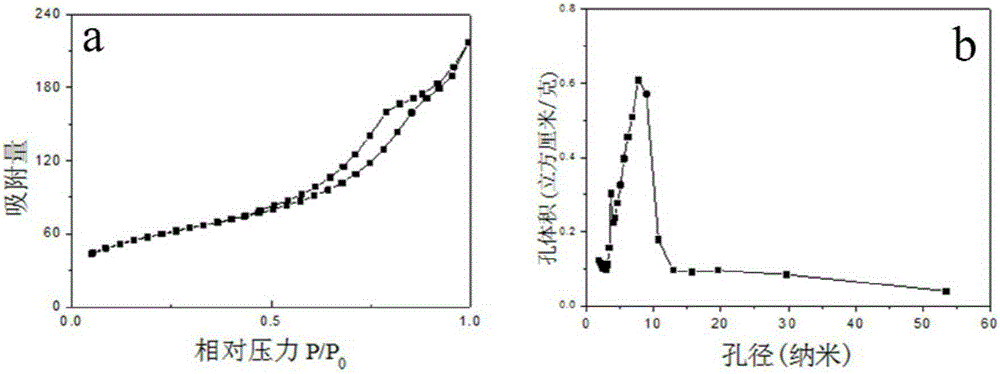

[0025] Test results: The morphology of the prepared catalyst is a core-shell structure with a cavity, and a needle-like structure with small particles growing on the spherical outer surface. The particle size of the core-shell ball is about 1-2um, the diameter of the cavity is about 200nm, and the specific surface of the catalyst is about 189m 2 / g, the m...

Embodiment 2

[0027] Under water bath conditions, add 140uL (1.27mmol) of titanium tetrachloride to 30mL of tert-butanol and 10mL of ethylene glycol, stir vigorously until titanium tetrachloride is completely dissolved to form a transparent solution, and 1.0g of tungsten hexachloride (2.52 mmol) was dissolved in 50mL of absolute ethanol, and then the above mixed solution was transferred to a 100mL polytetrafluoroethylene kettle (accounting for about 90% of the kettle volume), kept at 160°C for 48h, cooled to room temperature naturally, and centrifuged to prepare Hollow core-shell structure TiO 2 / WO 3 composite photocatalyst.

[0028] Test results: Through SEM and TEM spectrum tests, it is found that the morphology of the catalyst is a core-shell structure with a cavity, and a needle-like structure with small particles growing on the spherical outer surface. The particle size of the core-shell ball is about 1-2um, and the diameter of the cavity is about 200nm. , the specific surface area ...

Embodiment 3

[0030] Under water bath conditions, add 280uL (2.54mmol) of titanium tetrachloride to 30mL of tert-butanol and 10mL of ethylene glycol, stir vigorously until titanium tetrachloride is completely dissolved to form a transparent solution, and 0.5g of tungsten hexachloride (1.26 mmol) was dissolved in 50mL of absolute ethanol, and then the above mixed solution was transferred to a 100mL polytetrafluoroethylene kettle (accounting for about 90% of the kettle volume), kept at 160°C for 48h, cooled to room temperature naturally, and centrifuged to prepare Hollow core-shell structure TiO 2 / WO 3 composite photocatalyst.

[0031] Test results: Observed by a scanning electron microscope (SEM), the catalyst is a spherical structure with a core-shell, with small particles attached to the outer surface, and the specific surface area of the catalyst is about 165m 2 / g The needle-like structure disappears.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Cavity diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com