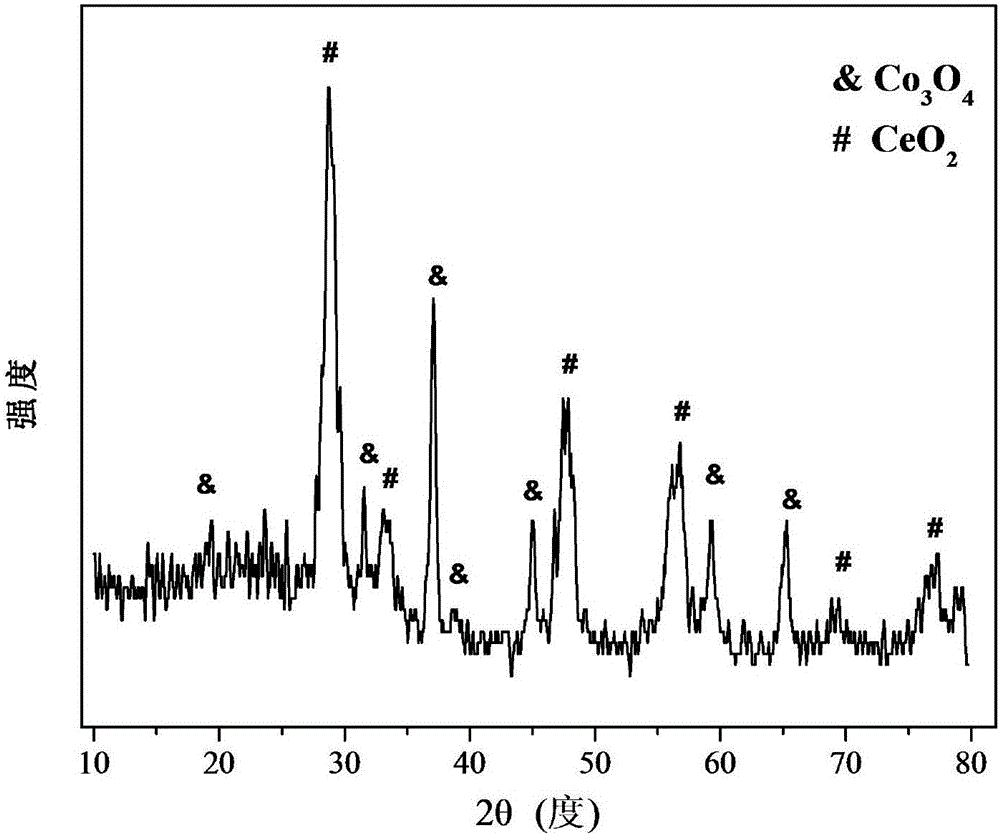

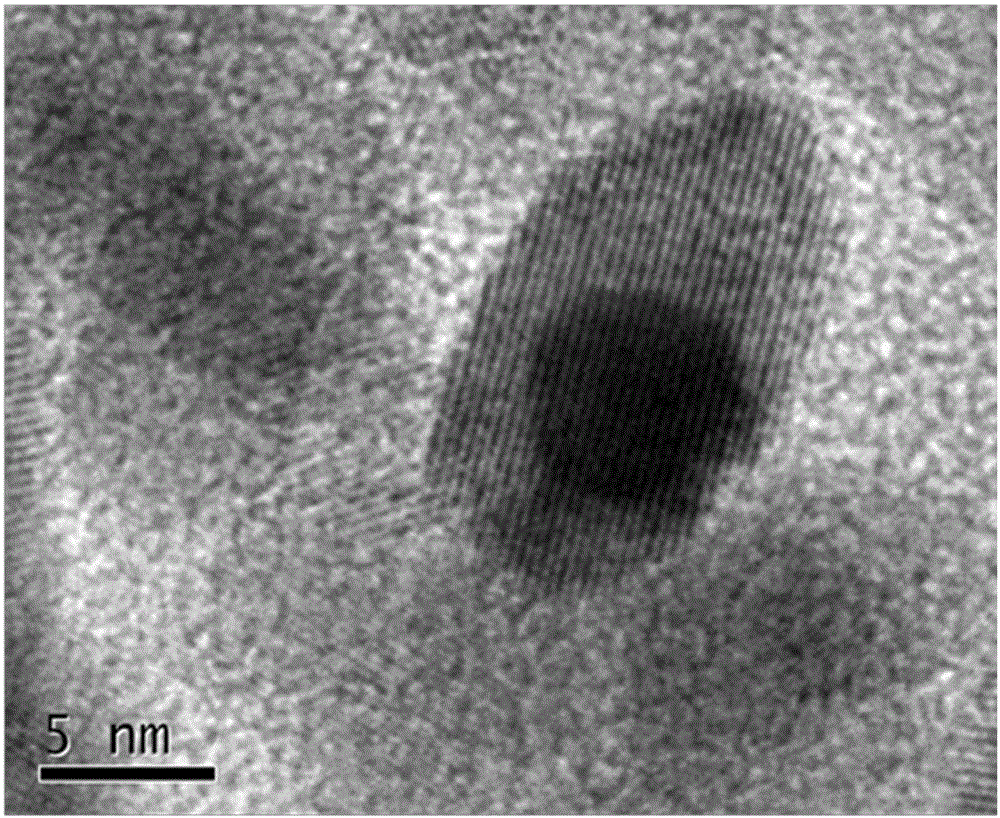

Modified Co-Ce core-shell structure catalyst for carbon monoxide (CO) low-temperature oxidation

A carbon monoxide, core-shell structure technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, air quality improvement, etc., can solve the problem of large mass transfer diffusion resistance and low porosity mass transfer diffusion and adsorption activation to achieve the effect of increasing the contact interface, improving the oxygen transfer capacity, and increasing the porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 14.50 g of Co(NO 3 ) 2 .6H 2 O and 26.90 g CO(NH 2 ) 2 , add 50 ml of deionized water and mix to form a solution, place it in a constant temperature water bath at 70°C for 30 minutes under magnetic stirring, then transfer it to a hydrothermal reaction kettle, keep it at 180°C for 12 hours, take it out, filter and wash; transfer the obtained filter cake to into a mixture of 25ml of water and 25ml of ethanol, and stirred to obtain suspension #1. Weigh 5.72 grams of Ce(NO 3 ) 3 .9H 2 O, dissolved in 13 ml of deionized water to form solution #2; slowly drop solution #2 into suspension #1 and form a homogeneous mixture under stirring, then add 0.96 g of CTAB and ultrasonically stir in a 70°C water bath 12h to form a core-shell structure precursor. After filtering and washing the obtained precursor, weigh 4 grams, transfer to 50ml of 0.5mol / L formic acid solution, stir at room temperature for 30min, then filter, wash, dry at 105°C for 12h, and roast at 500°C Af...

Embodiment 2

[0029] Weigh 14.50 g of Co(NO 3 ) 2 .6H 2 O and 26.90 g CO(NH 2 ) 2 , add 50 ml of deionized water and mix to form a solution, place it in a constant temperature water bath at 70°C for 30 minutes under magnetic stirring, then transfer it to a hydrothermal reaction kettle, keep it at 180°C for 12 hours, take it out, filter and wash; transfer the obtained filter cake to into a mixture of 25ml of water and 25ml of ethanol, and stirred to obtain suspension #1. Weigh 5.72 grams of Ce(NO 3 ) 3 .9H 2 O, dissolved in 13 mL of deionized water to form solution #2. Slowly drop solution #2 into suspension #1, and form a homogeneous mixture under stirring, then add 0.96 g of CTAB, and ultrasonically stir for 12 h in a water bath at 70°C to form a core-shell structure precursor. After filtering and washing the obtained precursor, weigh 4 grams, transfer to 50ml of 1.0mol / L formic acid solution, stir at room temperature for 30min, then filter, wash, dry at 105°C for 12h, and roast at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com