Dry-wet-method mineral separation method used for African sandy diatomite ore

A beneficiation method and technology of diatomite ore, which is applied in the field of dry and wet beneficiation of sandy diatomite ore in Africa, can solve the problems that it is difficult to apply ultra-low-grade sandy diatomite ore to beneficiation and purification, and achieve stable equipment High reliability and reliability, high recovery rate of diatoms and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] This embodiment will introduce a specific implementation process of the dry and wet method for beneficiation of sandy diatomite ore in Africa. This process includes two parts, one part is the dry separation process, and the other part is the dry separation process. The results were wet sorted.

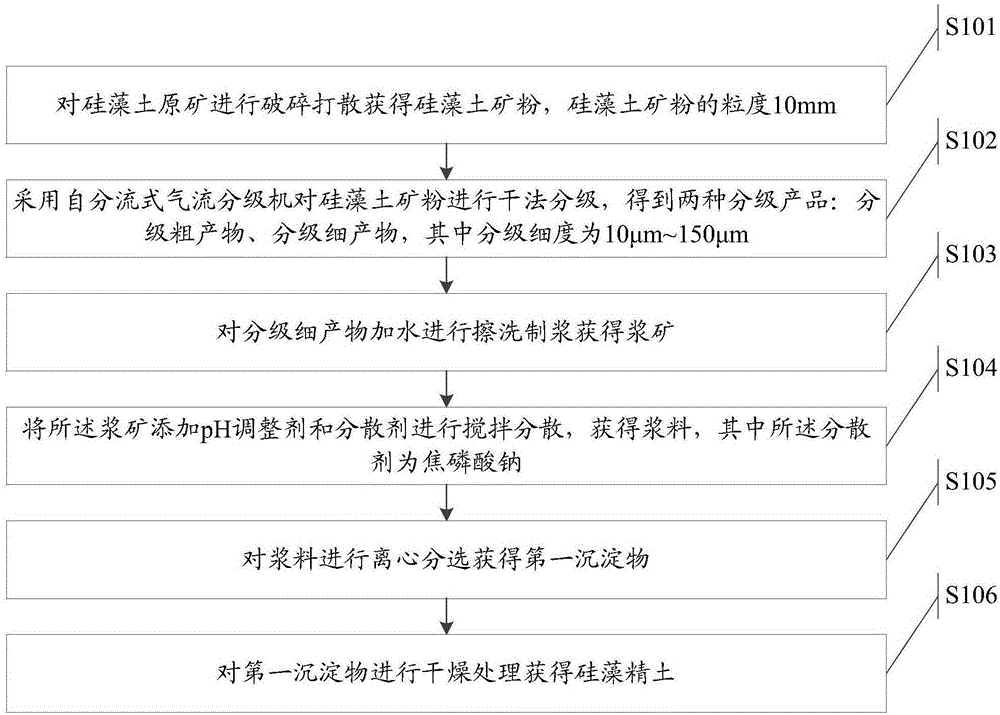

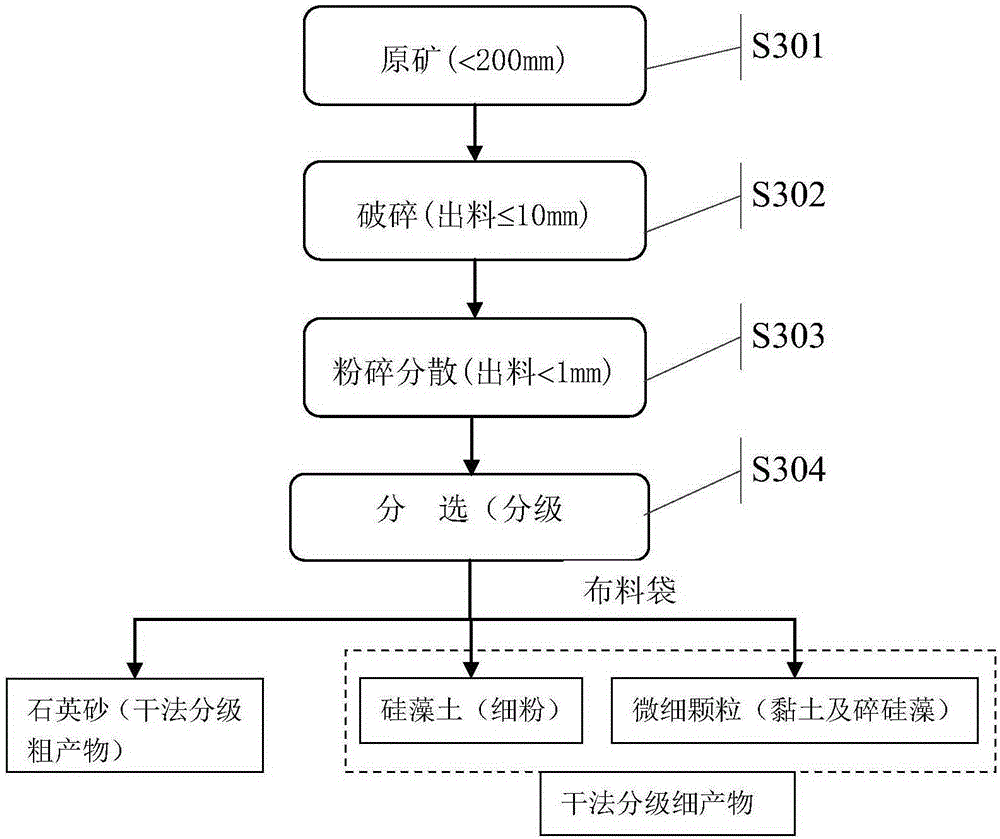

[0071] Please refer to image 3 , the dry sorting process comprises the following steps:

[0072] Step S301: Obtain diatomite raw ore with a particle size of less than 200mm;

[0073] Step S302: crushing diatomite raw ore to obtain diatomite mineral powder, the particle size of diatomite mineral powder is less than or equal to 10mm;

[0074] Step S303: After obtaining the diatomite mineral powder, the diatomite mineral powder can be further pulverized and dispersed, and the particle size of the dispersed diatomite mineral powder is ≤1mm;

[0075] Step S304: Carry out dry sorting, the result of dry sorting includes dry classified crude product and dry classified fine product, ...

Embodiment 2

[0090] 2000kg (moisture content 5%) diatomite raw ore with a diatomite content of about 20% is crushed and dispersed by a LHI-70 horizontal impact mill and then fed into a LHB-N self-distributing airflow classifier for separation. Continuously feed and run for 40 minutes to obtain two graded products (1# coarse powder 1456kg (coarse sand), 2# fine powder 545kg); put 545kg graded fine powder and 800L of clean water into the ZCX-0.25×2 double-slot scrubbing machine for scrubbing And use sodium hydroxide to adjust the pH of the pulp to 9.5, and the scrubbing time is 20 minutes; the pulp after scrubbing enters the mixing tank, and 1380L of water and 850g of sodium pyrophosphate are added while stirring to disperse; the dispersed pulp is fed into a horizontal centrifugal concentrator for Separation of clay and diatomite, centrifugation factor 2400, centrifugation precipitate obtained 438kg of diatomite (moisture content about 8%) after pressure filtration and drying.

Embodiment 3

[0092] 2000kg (moisture content 5%) diatomite raw ore with a diatomite content of about 20% is crushed and dispersed by a LHI-70 horizontal impact mill and then fed into a LHB-N self-distributing airflow classifier for separation. Continuously feed and run for 40 minutes to obtain two graded products (1# coarse powder 1456kg (coarse sand), 2# fine powder 545kg); put 545kg graded fine powder and clean water 900L into the ZCX-0.25×2 double-slot scrubbing machine for scrubbing And use sodium hydroxide to adjust the pH of the pulp to 10, and the scrubbing time is 20 minutes; the pulp after scrubbing enters the mixing tank, and 1600L of water and 850g of sodium pyrophosphate are added while stirring to disperse; the dispersed pulp is fed into a horizontal centrifugal concentrator for Separation of clay and diatomite, centrifugation factor 2800, centrifuge precipitate obtained 445kg of diatomite (moisture content about 8%) after pressure filtration and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com