Large-scale synthesis method of two-dimensional graphene-like carbon material by using sodium citrate

A technology of sodium citrate and graphene, which is applied in the field of synthesis of two-dimensional graphene-like carbon materials, can solve the problems of difficulty in large-scale production, complicated operation process, and high cost, and achieve large-scale industrial production and short reaction cycle Short, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

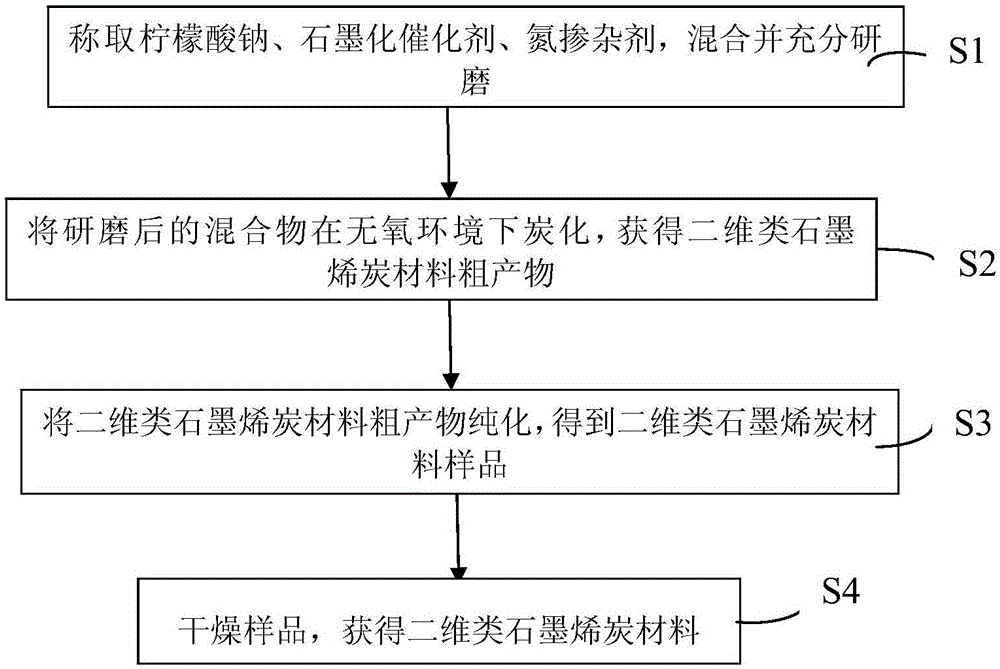

[0031] The invention provides a method for synthesizing a two-dimensional graphene-like carbon material that is environmentally friendly, low in price, short in reaction cycle, easy to operate, and less demanding on reaction conditions. The technological process of the synthetic method of this two-dimensional graphene-like carbon material is as follows figure 1 As shown, it specifically includes the following steps:

[0032] S1: Weigh a certain mass ratio of sodium citrate, graphitization catalyst and nitrogen dopant as raw materials, mix and fully grind;

[0033] S2: carbonizing the ground raw material in an oxygen-free environment to obtain a crude product of a two-dimensional graphene-like carbon material;

[0034] S3: purifying the crude product of the two-dimensional graphene-like carbon material to obtain a two-dimensional graphene-like carbon material sample;

[0035] S4: drying the sample to obtain a two-dimensional graphene-like carbon material.

[0036] By changin...

Embodiment 1

[0046] S1: Weigh 1.0 g of sodium citrate and grind it thoroughly.

[0047] S2: Transfer the ground sodium citrate to the porcelain boat of the horizontal tube furnace, pass inert gas for 30 minutes to make the horizontal tube furnace an oxygen-free environment, and then continue to heat the mixture at 4°C min under the inert atmosphere. –1 The heating rate is heated to 600 ° C, and the temperature is kept in an inert gas flow for 1 hour, and then taken out to obtain a crude product of a two-dimensional amorphous carbon material;

[0048] S3: immersing the crude two-dimensional amorphous carbon material in acid to remove impurities. Then filter with suction and rinse with deionized water until neutral.

[0049] S4: heat the sample to 110° C. in a vacuum drying oven and keep it for 12 hours to obtain a two-dimensional amorphous carbon material.

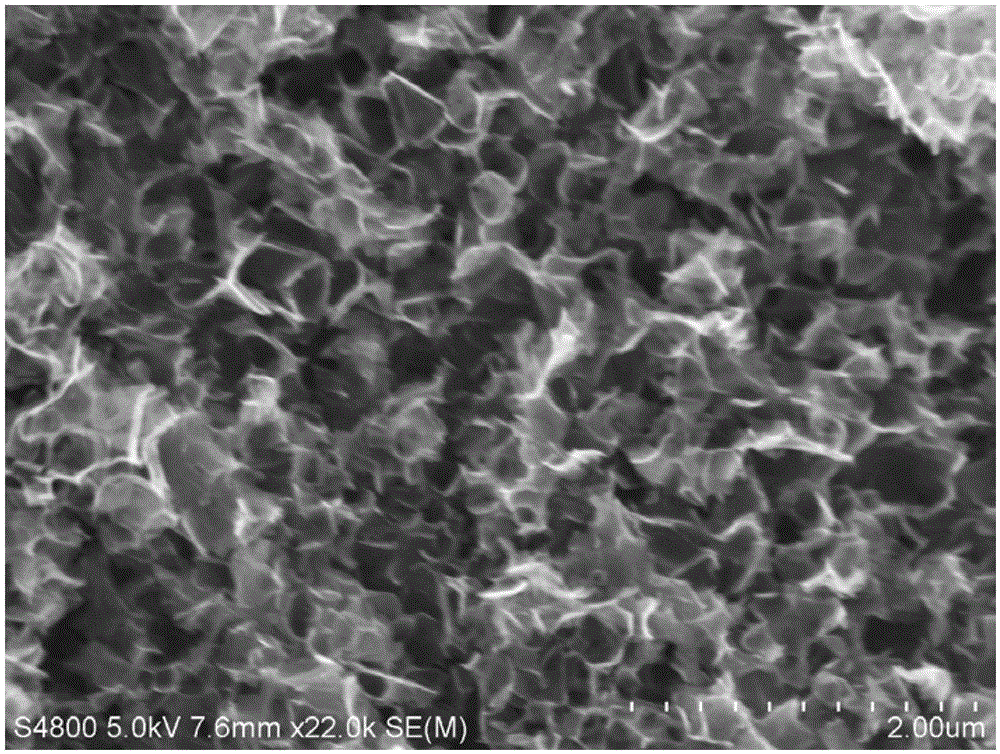

[0050] figure 2 It is a scanning electron micrograph of the sample obtained in this embodiment, and it can be seen from the figure...

Embodiment 2

[0054] S1: Weigh 1.0 g of sodium citrate and 1.0 g of melamine, mix and grind thoroughly.

[0055] S2: Transfer the ground mixture to the porcelain boat of the horizontal tube furnace, pass inert gas for 30 minutes to make the horizontal tube furnace an oxygen-free environment, and then continue to heat at 4°C min under the inert atmosphere. –1 The heating rate was heated to 1000 ° C, and then kept in an inert gas flow for 4 hours and then taken out to obtain a crude product of a two-dimensional amorphous nitrogen-doped carbon material.

[0056] S3: immersing the crude product of the obtained two-dimensional amorphous nitrogen-doped carbon material in acid to remove impurities. Then filter with suction and rinse with deionized water until neutral.

[0057] S4: Heat the sample to 110° C. in a vacuum drying oven and keep it for 12 hours to obtain a two-dimensional amorphous nitrogen-doped carbon material.

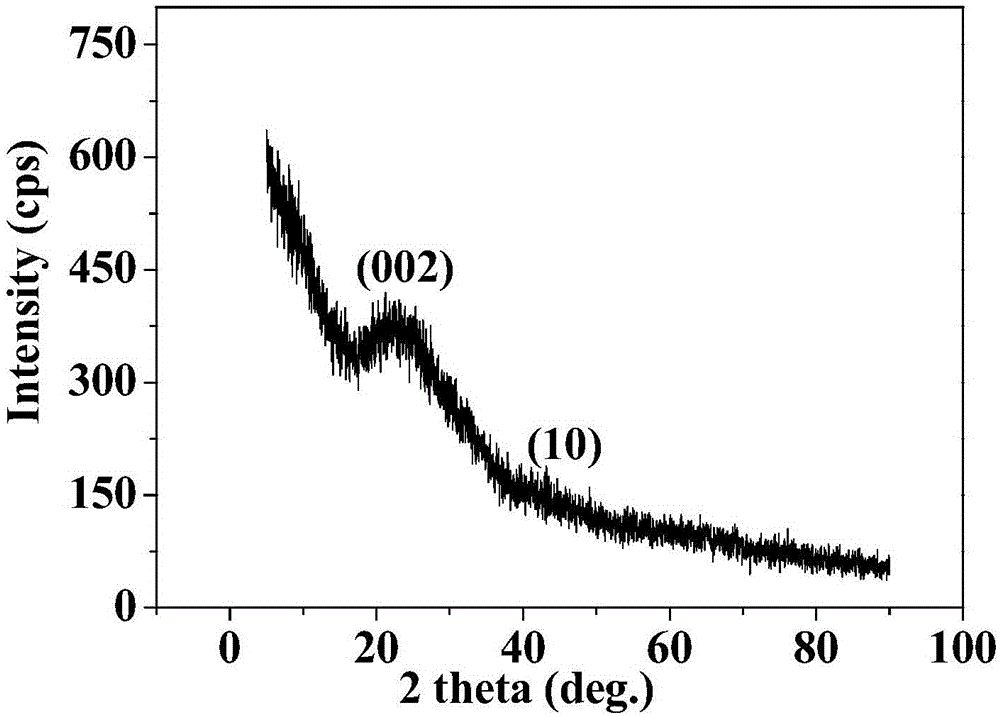

[0058] Figure 5 It is a scanning electron microscope image of the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com