Treatment method for bamboo pulp wastewater

A treatment method and technology for wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of foam dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

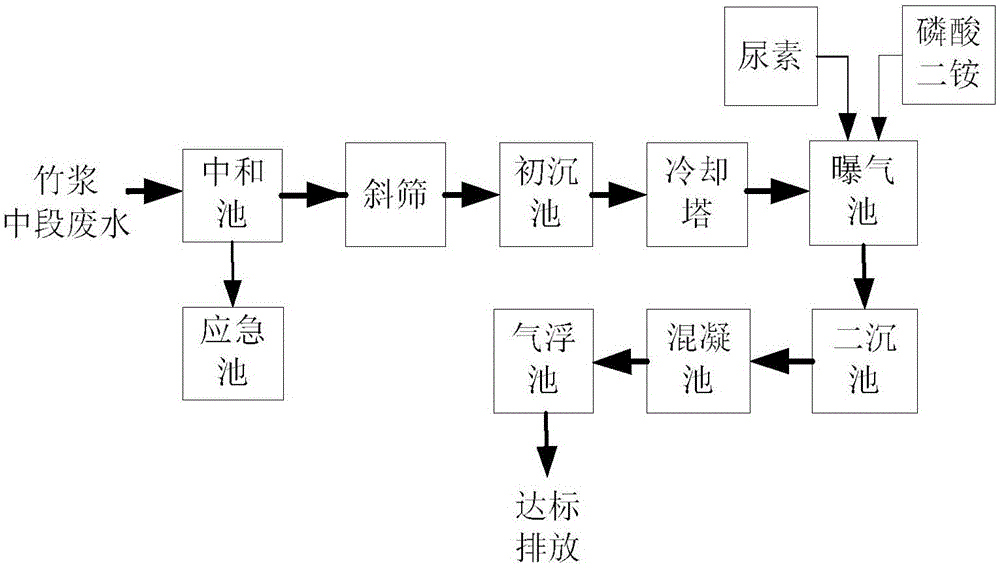

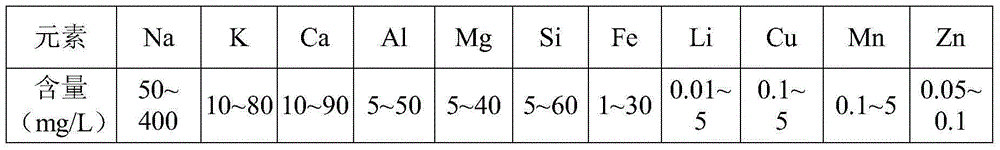

[0028] as attached figure 1 , is a typical bamboo pulp wastewater treatment process, and the wastewater is discharged up to standard after neutralization, screening, sedimentation, cooling, aeration, secondary sedimentation, coagulation, and air flotation. figure 1 The emergency pool in the neutralization pool is used for temporary storage when the water volume of the neutralization pool fluctuates greatly, and acts as a buffer. During the aeration process, microorganisms also need to take in enough nitrogen and phosphorus when taking in the carbon source of organic pollutants. For a long time, a large amount of urea or biologically active nitrogen has been added as a nitrogen source in the biological treatment process of wastewater from all papermaking enterprises at home and abroad, and a large amount of phosphate or phosphoric acid has been added as a phosphorus source at the same time (biologically active nitrogen is used in pulp and paper industry wastewater treatment. A...

Embodiment 2

[0038] In the 7 years since the establishment of the wastewater treatment station in 2008, during the normal production of the enterprise, the wastewater treatment station has processed 20,000 tons of mid-stage water every day, and added 440kg of urea and 125kg of trisodium phosphate to the aerobic pool every day. The new technology obtained in the laboratory is now applied to the production of the enterprise. In order to gradually adapt the aerobic bacteria in the aeration tank to the waste water environment with reduced nitrogen and phosphorus, a method of decreasing the dosage of urea and trisodium phosphate every month is adopted. The program of decreasing nitrogen and phosphorus dosage in the aeration tank (see Table 2). From April 1, 2015, the daily input of urea into the aeration tank was reduced from 440 kg to 300 kg, and the daily input of phosphoric acid into the aeration tank The amount of trisodium 125 kg remains unchanged. At the end of April, the one-month engine...

Embodiment 3

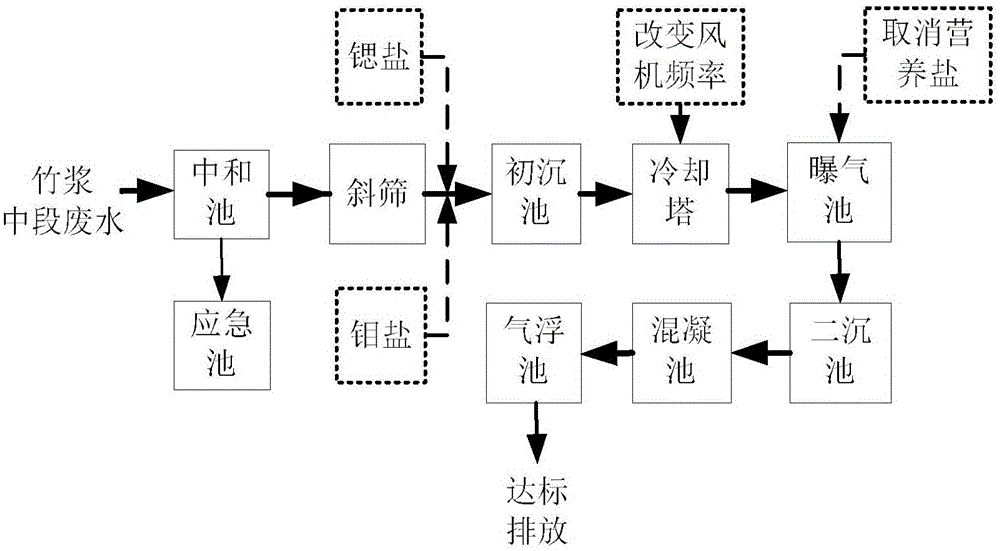

[0058] Another bamboo pulp factory in Southwest China produces 8,000 tons of mid-stage wastewater every day. This new method of bamboo pulp wastewater treatment is adopted, and the dosage of urea and diammonium phosphate is gradually reduced within 3 months, and added to the primary sedimentation tank every day. Sodium molybdate and strontium chloride are each 0.4 kg, and cooling tower fan inverters are added to reduce the fan frequency month by month. By the fourth month, the wastewater treatment project is operating normally, and the main indicator of discharged wastewater is COD 75-90mg / L, in line with GB3544 -2008 National Emission Standards. In addition, the total nitrogen in the discharged wastewater is reduced by 21%, and the total phosphorus is reduced by 37%. The waste water treatment cost in the fourth month is 27,000 yuan lower than before the implementation of the new method, and the annual comprehensive cost can be saved by 300,000 yuan.

[0059] As can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com