Production method and continuous steam-pressure device of acid soil improver

An acid soil and production method technology, applied in soil conditioning materials, fertilization devices, chemical instruments and methods, etc., can solve the problems of low energy utilization efficiency, high cost, large pressure loss, etc., to improve production efficiency and energy utilization. efficiency, improving soil micro-ecological environment, and being suitable for a large number of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Crushing of ore: crush potassium feldspar, quicklime, magnesite, boronite lump ore through a pulverizer to a material with a particle size of less than 1cm;

[0055] (2) Mix 38 parts of potassium feldspar, 28 parts of quicklime, 11 parts of magnesite, 6 parts of boronite, 12 parts of a mixture of weathered coal and lignite, and 4 parts of activated auxiliary materials, and transport them to a ball mill for grinding until powder The particle size of the material is 100 mesh; the above-mentioned "parts" are parts by weight;

[0056] (3) Put the ground material in step (2) into the mixer, add water and stir evenly, so that the moisture content of the material is about 25%, and then send the material into the compression mold in the compression molding machine, and press it into a block;

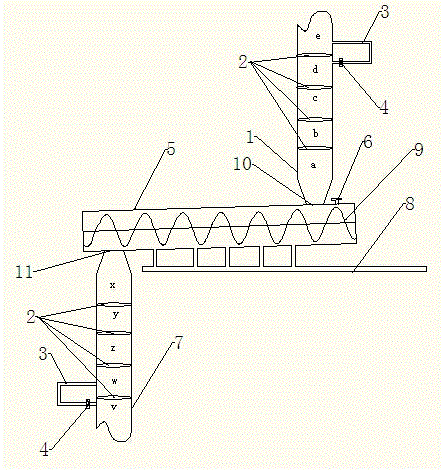

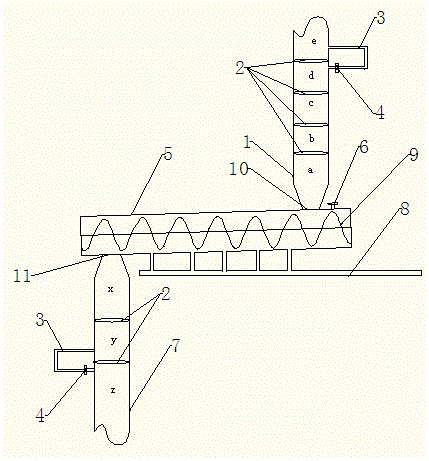

[0057] (4) Transfer the bulk raw material formed by compression molding in step (3) to a continuous autoclaving device for reaction. The reaction conditions are: feed high temperature...

Embodiment 2

[0070] a. Crushing of ores: The massive ores such as potassium feldspar and quicklime are crushed into materials with a particle size of less than 1cm through a jaw crusher.

[0071] b. Mixed grinding of ore: The required raw materials are according to the mass ratio: 35 parts of potassium feldspar, 25 parts of quicklime, 12 parts of magnesite, 7 parts of boron magnesium ore, 15 parts of weathered coal / lignite, 5 parts of activated auxiliary materials, Mix evenly, enter the ball mill, and grind until the particle size of the powder is greater than 100 mesh;

[0072] c. Powder compression molding: the ground mixed powder enters the mixer, adds water and stirs evenly to form a wet material with a water content of 20-30%, and then enters the compression molding machine to be pressed into blocks;

[0073] d. Hydrothermal autoclaving reaction: put the compression molded raw material block on the steam curing car, push it into the continuous autoclaving device, close the kettle door...

Embodiment 3

[0076] a. Crushing of ores: The massive ores such as potassium feldspar and quicklime are crushed into materials with a particle size of less than 1cm through a jaw crusher.

[0077] b. Mixed grinding of ore: The required raw materials are according to the mass ratio: 37 parts of potassium feldspar, 28 parts of quicklime, 10 parts of magnesite, 5 parts of boron magnesium ore, 10 parts of weathered coal / brown coal, 2 parts of activated auxiliary materials, Mix evenly, enter the ball mill, and grind until the particle size of the powder is greater than 100 mesh;

[0078] c. Powder compression molding: the ground mixed powder enters the mixer, adds water and stirs evenly to form a wet material with a water content of 20-30%, and then enters the compression molding machine to be pressed into blocks;

[0079] d. Hydrothermal autoclaving reaction: put the molded raw material block on the steam curing car, push it into the continuous autoclaving device, close the kettle door of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com