LED having N type AlInGaN contact layer and preparation method

A contact layer, N-type technology, applied in the field of optoelectronics, can solve problems such as unfavorable production stability, shorten the maintenance cycle of MOCVD equipment, etc., and achieve the effects of improving the quality of P-type GaN films, improving external quantum efficiency, and increasing hole concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

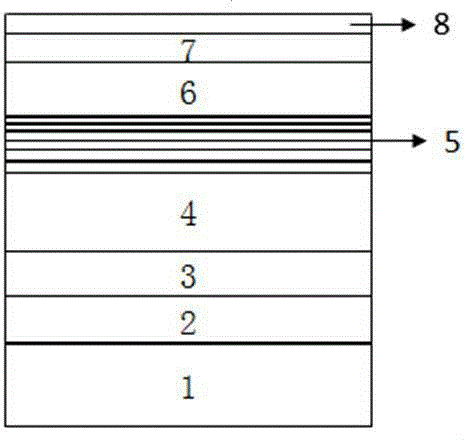

[0036] LED with N-type AlInGaN contact layer of the present invention such as figure 1 As shown, it includes substrate 1, nucleation layer 2, buffer layer 3, N-type GaN layer 4, multi-quantum well light-emitting layer 5 and P-type structure from bottom to top, and the P-type structure is P-type AlGaN layer 6, P-type GaN layer 7 and N-type AlInGaN contact layer 8 .

[0037] In this embodiment, the substrate 1 is a silicon carbide substrate. The nucleation layer 2 is an aluminum nitride layer with a thickness of 30 nm. The buffer layer 3 is a non-doped GaN layer with a thickness of 2 μm. The thickness of the N-type GaN layer 4 is 2 μm. The multi-quantum well light-emitting layer 5 is composed of 15 cycles of InGaN potential well layers and GaN barrier layers alternately superimposed, with a total thickness of 225nm. In a single cycle, the thickness of the InGaN potential well layer is 3nm, and the thickness of the GaN barrier layer is 12nm. The Mg doping concentration in the...

Embodiment 2

[0049] In this embodiment, the substrate 1 is a sapphire substrate. The nucleation layer 2 is an AlGaN layer with a thickness of 120nm. The buffer layer 3 is a non-doped GaN layer with a thickness of 1.8 μm. The thickness of the N-type GaN layer 4 is 2.5 μm. The multi-quantum well light-emitting layer 5 is composed of 18 periods of InGaN potential well layers and GaN barrier layers alternately superimposed, with a total thickness of 270nm. In a single period, the thickness of the InGaN potential well layer is 2nm, and the thickness of the GaN barrier layer is 14nm. . The Mg doping concentration in the P-type AlGaN layer 6 is 9.8×10 18 / cm -3 . The Mg doping concentration in the p-type GaN layer 7 is 8×10 19 / cm -3 . The thickness of the N-type AlInGaN contact layer 8 is 80 nm.

[0050] The preparation process of the above-mentioned LED having an N-type AlInGaN contact layer specifically includes the following steps:

[0051] (1) Put the sapphire substrate in the reac...

Embodiment 3

[0061] In this embodiment, the substrate 1 is a sapphire substrate. The nucleation layer 2 is a gallium nitride layer with a thickness of 600nm. The buffer layer 3 is a non-doped GaN layer with a thickness of 1.5 μm. The thickness of the N-type GaN layer 4 is 1.5 μm. The multi-quantum well light-emitting layer 5 is composed of 12 periods of InGaN potential well layers and GaN barrier layers alternately superimposed, with a total thickness of 210nm. In a single period, the thickness of the InGaN potential well layer is 3.5nm, and the thickness of the GaN barrier layer is 14nm. The Mg doping concentration in the P-type AlGaN layer 6 is 1.2×10 18 / cm -3 . The Mg doping concentration in the p-type GaN layer 7 is 5×10 19 / cm -3 . The thickness of the N-type AlInGaN contact layer 8 is 2 nm.

[0062] The preparation process of the above-mentioned LED having an N-type AlInGaN contact layer specifically includes the following steps:

[0063] (1) Put the sapphire substrate in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com