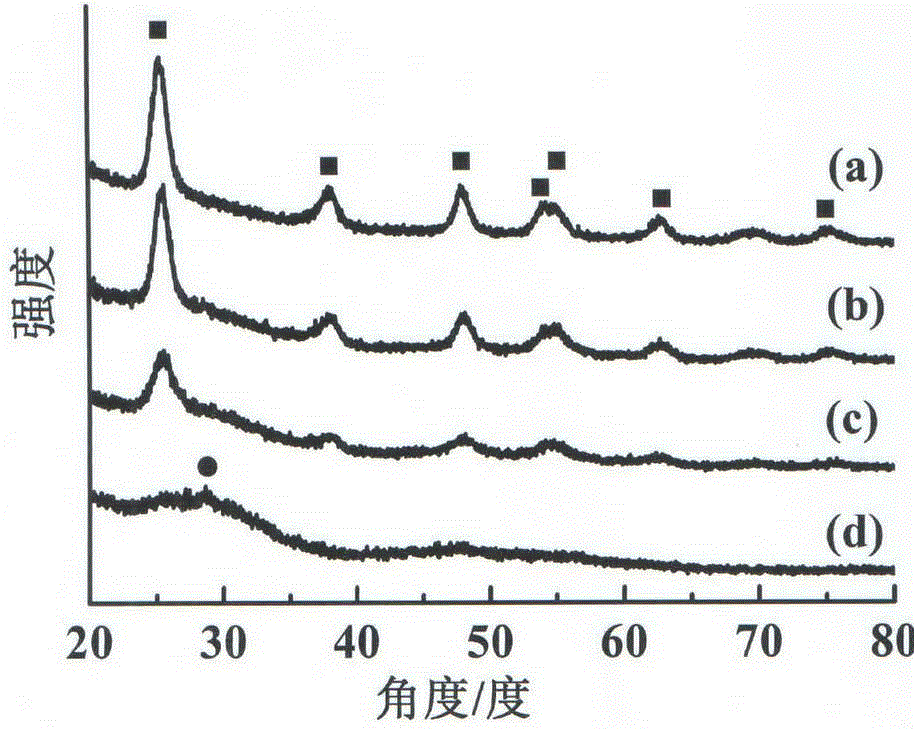

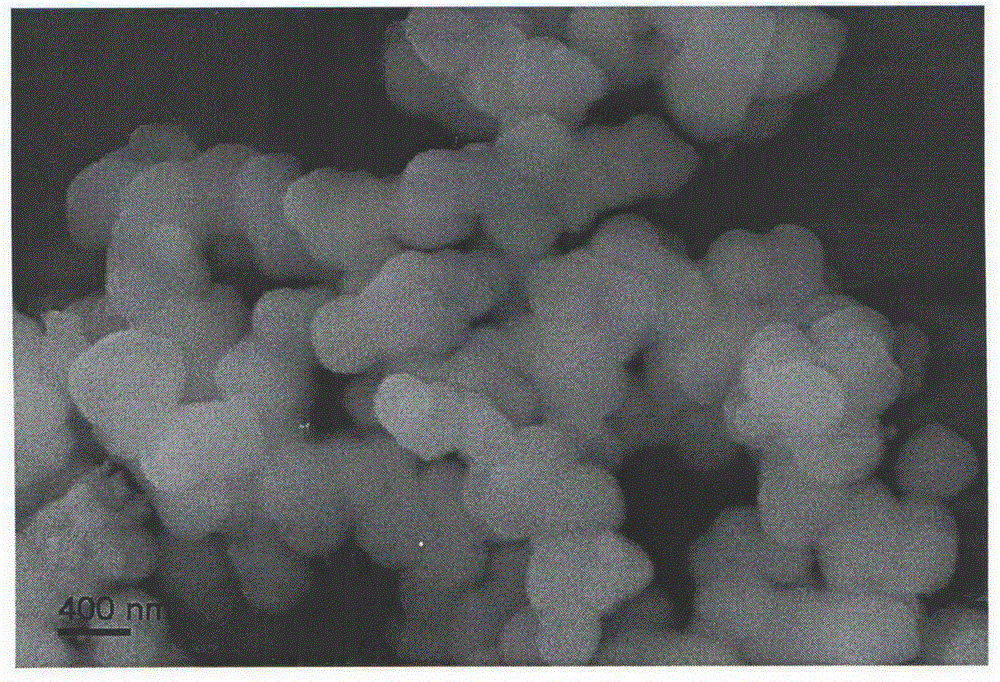

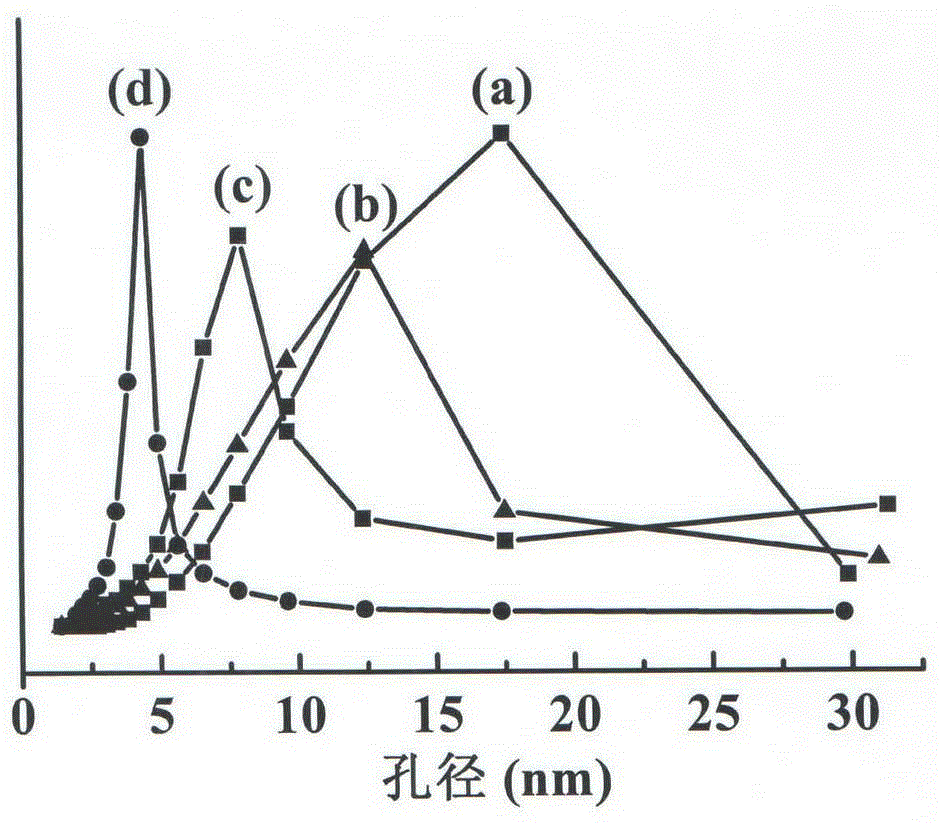

Preparation method and application of high-dispersion CeO2 modified TiO2 meso-porous photocatalyst

A photocatalyst and high-dispersion technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. gender issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]a. Disperse 0.4 g of a water-soluble titanium source di(2-hydroxypropionic acid) diammonium titanium hydroxide solution with a mass percentage of 50% in 120 ml of deionized water;

[0029] b. Weigh the cerium source as 0.045g cerium nitrate hexahydrate solid, add it to the aqueous solution in step a, and stir at room temperature to completely dissolve the cerium nitrate hexahydrate to obtain a mixed solution;

[0030] c. Add 0.1 g of polyethylene glycol (W=6000) to the mixed solution in step b, and stir at room temperature until it is completely dissolved;

[0031] d. Transfer the mixed solution obtained in step c into a high-pressure hydrothermal reaction kettle, and react for 2 hours at a temperature of 250° C. under stirring conditions to obtain a slurry;

[0032] e. Centrifuge the slurry obtained in step d at 11,000 rpm for 5 minutes to obtain a pale yellow precipitate;

[0033] f. Wash the precipitate obtained in step e twice with deionized water and once with abso...

Embodiment 2

[0036] a. Disperse 0.3 g of a titanium source of 50% by mass percentage in 120 ml of deionized water;

[0037] b. Weigh the cerium source as 0.09 cerium nitrate hexahydrate solid, add it to the aqueous solution in step a, stir at room temperature to completely dissolve the cerium nitrate hexahydrate, and obtain a mixed solution;

[0038] c. Add 0.3 g of polyethylene glycol (W=2000) to the mixed solution obtained in step b, and stir at room temperature to completely dissolve the polyethylene glycol to obtain a mixed solution;

[0039] d. Transfer the mixed solution obtained in step c into an autoclave, heat it for 1 hour at a temperature of 180° C. under stirring conditions, and perform a hydrothermal decomposition reaction to obtain a slurry;

[0040] e. Centrifuge the slurry obtained in step d at 11,000 rpm for 5 minutes to obtain a pale yellow precipitate;

[0041] f. Wash the precipitate obtained in step e twice with deionized water and once with absolute ethanol, and then...

Embodiment 3

[0044] a. Disperse 0.5 g of a titanium source of 50% by mass percentage in 120 ml of deionized water;

[0045] b. Weigh the cerium source as 0.0002 cerium nitrate hexahydrate solid, add it to the aqueous solution in step a, stir at room temperature to completely dissolve the cerium nitrate hexahydrate, and obtain a mixed solution;

[0046] c. Add 0.15 g of polyethylene glycol (W=2000) to the mixed solution obtained in step b, and stir at room temperature to completely dissolve the polyethylene glycol to obtain a mixed solution;

[0047] d. Transfer the mixed solution obtained in step c into an autoclave, heat it for 2 hours at a temperature of 200° C. under stirring conditions, and perform a hydrothermal decomposition reaction to obtain a slurry;

[0048] e. Centrifuge the slurry obtained in step d at 11,000 rpm for 5 minutes to obtain a pale yellow precipitate;

[0049] f. Wash the precipitate obtained in step e twice with deionized water and once with absolute ethanol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com