Neodymium-doped bismuth ferrite nanometer photocatalyst and preparation method thereof

A nano-photocatalyst and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of low photon quantum efficiency and high photo-generated electron-hole recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

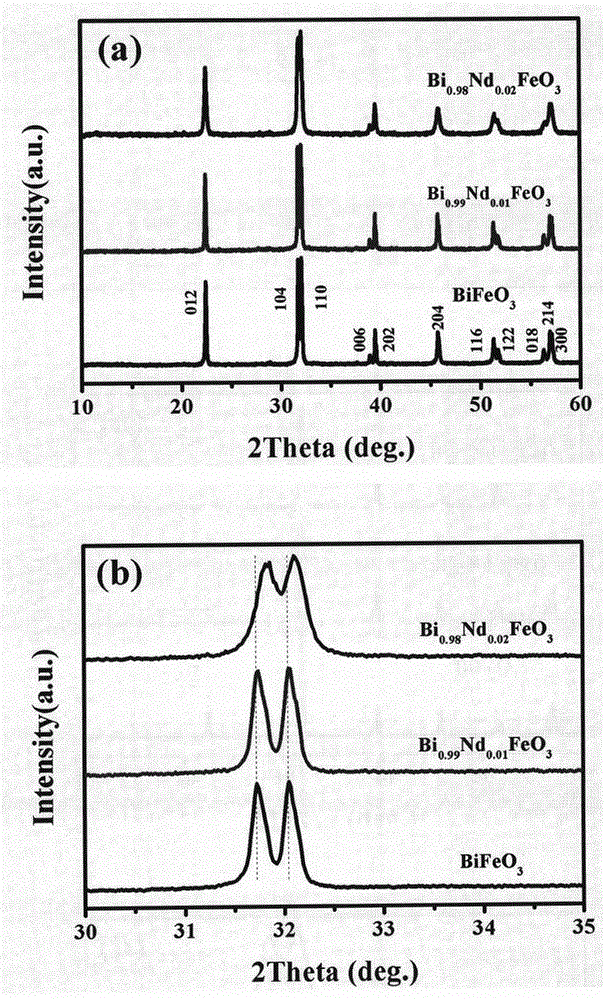

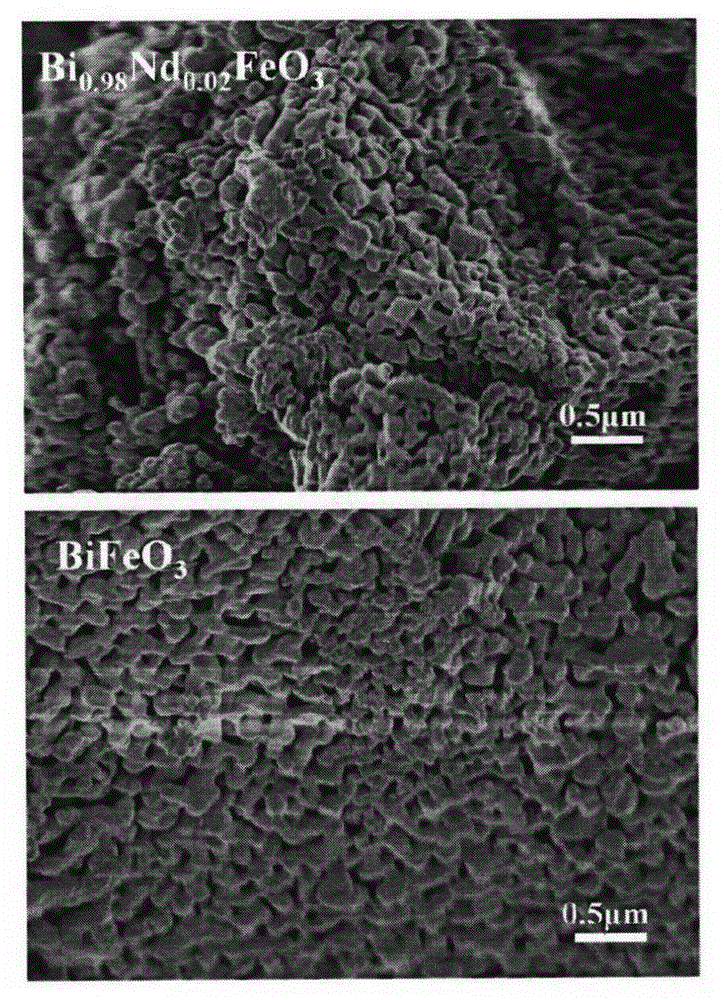

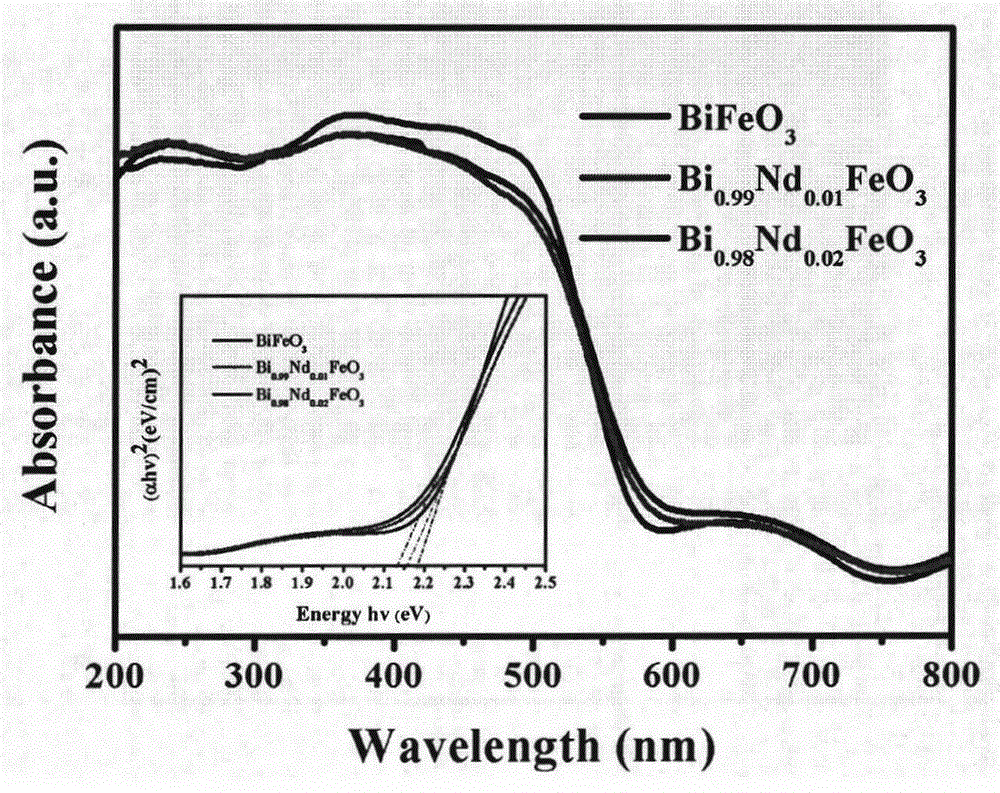

Embodiment 1

[0020] According to the chemical formula Bi 0.99 Nd 0.01 FeO 3 Weigh 4.802g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), 0.043g neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), 4.04g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), according to the chemical formula Bi 0.98 Nd 0.02 FeO 3 Weigh 4.753g bismuth nitrate pentahydrate, 0.087g neodymium nitrate hexahydrate, 4.04g ferric nitrate nonahydrate and according to the chemical formula BiFeO 3 Weigh 4.850g of bismuth nitrate pentahydrate and 4.04g of ferric nitrate hexahydrate and dissolve them in 130ml of 0.2mol / L tartaric acid ethylene glycol solution, mix and stir evenly, and the total molar concentration of cations in the solution is 0.15mol / L L; The obtained three different precursor solutions were heated to 80°C respectively, and kept heating for 2 hours to obtain three different sols; the obtained three sols were respectively placed in an oven at 110°C, and dried continuously to obtain three diff...

Embodiment 2

[0027] According to the chemical formula Bi 0.99 Nd 0.01 FeO 3 Weigh 4.802g bismuth nitrate pentahydrate (Bi(NO 3 )3 ·5H 2 O), 0.043g neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), 4.04g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), according to the chemical formula Bi 0.98 Nd 0.02 FeO 3 Weigh 4.753g bismuth nitrate pentahydrate, 0.087g neodymium nitrate hexahydrate, 4.04g ferric nitrate nonahydrate and according to the chemical formula BiFeO 3 Weigh 4.850g of bismuth nitrate pentahydrate and 4.04g of ferric nitrate hexahydrate and dissolve them in 200ml of 0.1mol / L tartaric acid ethylene glycol solution, mix and stir evenly, and the total molar concentration of cations in the solution is 0.1mol / L L; The obtained three different precursor solutions were heated to 70°C, and kept heating for 1.5h to obtain three different sols; the obtained three sols were respectively placed in an oven at 100°C, and dried continuously to obtain three different xerogels; Th...

Embodiment 3

[0030] According to the chemical formula Bi 0.99 Nd 0.01 FeO 3 Weigh 4.802g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), 0.043g neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), 4.04g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), according to the chemical formula Bi 0.98 Nd 0.02 FeO 3 Weigh 4.753g bismuth nitrate pentahydrate, 0.087g neodymium nitrate hexahydrate, 4.04g ferric nitrate nonahydrate and according to the chemical formula BiFeO 3 Weigh 4.850g of bismuth nitrate pentahydrate and 4.04g of ferric nitrate hexahydrate and dissolve them in 100ml of 0.3mol / L tartaric acid ethylene glycol solution, mix and stir evenly, and the total molar concentration of cations in the solution is 0.2mol / L L; The obtained three different precursor solutions were heated to 90°C respectively, and kept heating for 2.5h to obtain three different sols; the obtained three sols were respectively placed in an oven at 120°C, and dried continuously to obtain three differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com