Resource treatment process of 1-amino anthraquinone sulfurization reduction wastewater

A technology of aminoanthraquinone and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, inorganic chemistry, etc., and can solve problems such as inability to remove salt in wastewater, long treatment time, and large footprint , to achieve the effect of reducing organic matter, simple operation and lower operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

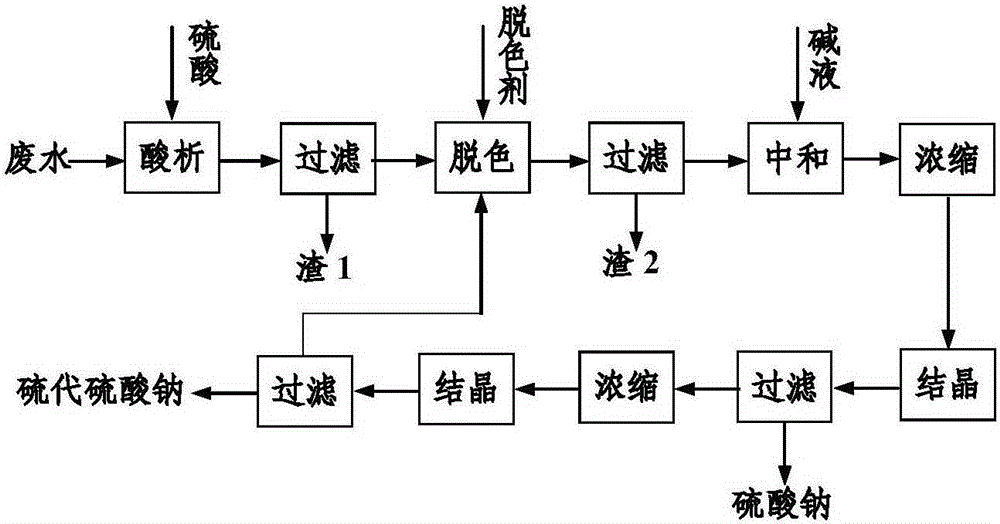

Image

Examples

Embodiment 1

[0024] 1-aminoanthraquinone sulfidation reduction wastewater from a chemical plant, COD is 33030mg / L, NH 3 -N is 620mg / L, salt content is 14%, pH=14, and the biodegradability is extremely poor. The sewage is treated as follows:

[0025] (1) Add sulfuric acid dropwise to the 1-aminoanthraquinone sulfidation reduction waste water to adjust the pH to 2, and absorb the harmful acid gas produced during the acid addition process with 10% sodium hydroxide. The waste water is filtered to remove the precipitated anthraquinone residue 1;

[0026] (2) Add 1% powdered activated carbon to waste water, stir and decolorize for 30 minutes, remove residue 2 by filtration to obtain purified waste water;

[0027] (3) adjust the pH of the purified waste water to 11 with 30% sodium hydroxide, then evaporate and concentrate to remove moisture, concentrate until the sodium sulfate content reaches 42%, and crystallize and filter to obtain sodium sulfate solid;

[0028] (4) The step (3) filter mothe...

Embodiment 2

[0030] 1-aminoanthraquinone sulfidation reduction wastewater from a chemical plant, COD is 28010mg / L, NH 3 -N is 530mg / L, salt content is 12%, pH=14, and the biodegradability is extremely poor. The sewage is treated as follows:

[0031] (1) Add sulfuric acid dropwise to the 1-aminoanthraquinone sulfidation-reduction wastewater to adjust the pH to 3, and absorb the harmful acid gas generated during the acid addition with 10% sodium hydroxide. The waste water is filtered to remove the precipitated anthraquinone residue 1;

[0032] (2) Add 1.5% powdered activated carbon to waste water, stir and decolorize for 50 minutes, remove residue 2 by filtration to obtain purified waste water;

[0033] (3) adjust the pH of purified waste water to 12 with 40% sodium hydroxide, then evaporate and concentrate to remove moisture under a vacuum of 0.85 MPa, concentrate until the sodium sulfate content reaches 50%, and crystallize and filter to obtain sodium sulfate solid;

[0034] (4) The moth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com