Long-acting and environmental-protection release agent and preparation method thereof

An environmentally friendly, release agent technology, applied in the field of materials, can solve problems such as reducing production efficiency and increasing production processes, and achieve the effects of improving production efficiency, reducing production processes, and eliminating hidden dangers in production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

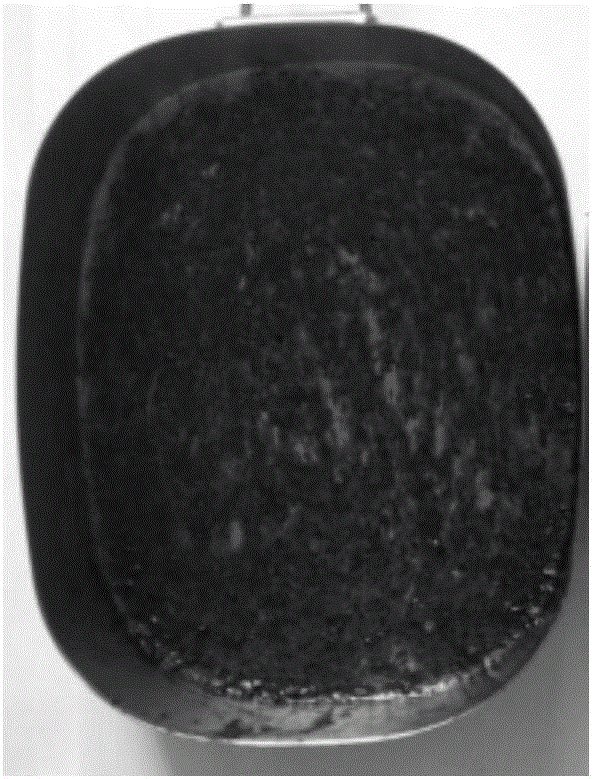

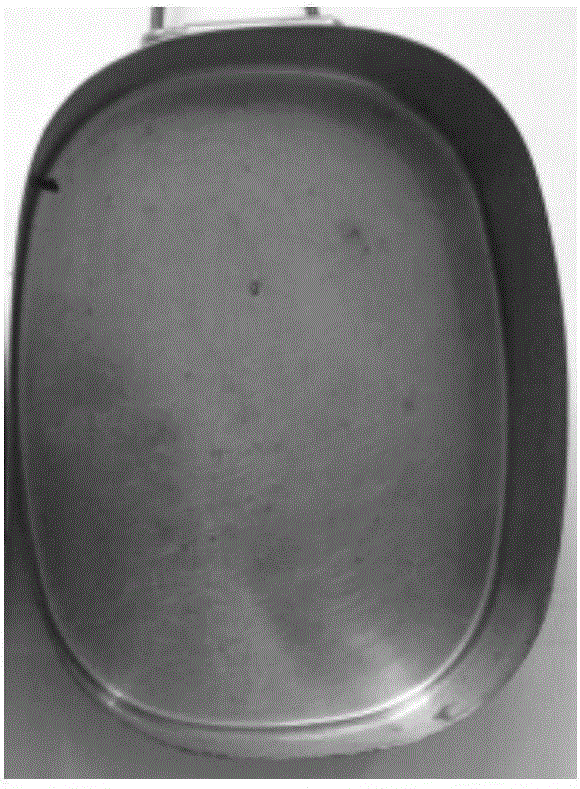

Image

Examples

Embodiment 1

[0024] 1. Preparation of emulsion system of chloroacetic acid

[0025] Add 40g of polyethylene glycol 400 and 3g of Carboresin 940 into 250g of distilled water, heat and dissolve evenly, add 10g of sodium lignosulfate, stir evenly, then add 100g of chloroacetic acid, and emulsify with a shearing machine to form a uniform emulsion to obtain Emulsion system of chloroacetic acid.

[0026] 2. Preparation of long-acting environment-friendly release agent

[0027] Under normal temperature conditions, add 150 g of hexamethylenediamine dropwise to the emulsion system of chloroacetic acid obtained in step 1. After the dropwise addition, react at room temperature for 2 hours to obtain a long-acting environmentally friendly isolation product with a light yellow viscosity of 1.58 Pa·s. agent.

Embodiment 2

[0029] 1. Preparation of emulsion system of chloroacetic acid

[0030] Add 20g of polyethylene glycol 300 and 2g of Carboresin 934 into 200g of distilled water, heat and dissolve evenly, add 5g of sodium lauryl sulfate, stir evenly, then add 100g of chloroacetic acid, emulsify with a shearing machine until a uniform emulsion is formed , to obtain the emulsion system of chloroacetic acid.

[0031] 2. Preparation of long-acting environment-friendly release agent

[0032] Under normal temperature conditions, add 100 g of hexamethylenediamine dropwise to the emulsion system of chloroacetic acid obtained in step 1. After the dropwise addition, react at room temperature for 2 hours to obtain a long-acting environment-friendly isolation product with a light yellow viscosity of 1.53 Pa s. agent.

Embodiment 3

[0034] 1. Preparation of emulsion system of chloroacetic acid

[0035] Add 30g of polyethylene glycol 200 and 5g of Carboresin 940 into 400g of distilled water, heat and dissolve evenly, add 10g of sodium dodecylbenzene sulfate, stir evenly, then add 100g of chloroacetic acid, emulsify with a shearing machine until uniform Emulsion, to obtain the emulsion system of chloroacetic acid.

[0036] 2. Preparation of long-acting environment-friendly release agent

[0037] Under normal temperature conditions, add 150 g of hexamethylenediamine dropwise to the emulsion system of chloroacetic acid obtained in step 1. After the dropwise addition, react at room temperature for 2 hours to obtain a long-acting environment-friendly isolation product with a light yellow viscosity of 1.51 Pa·s. agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com