3-ethoxy-4-methoxy benzonitrile preparing method

A technology of methoxybenzonitrile and methoxybenzaldehyde, which is applied in the field of preparation of 3-ethoxy-4-methoxybenzonitrile, can solve the problems of high risk factor, high cost, large pollution and the like, and achieves Low environmental pollution, low production cost and easy post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

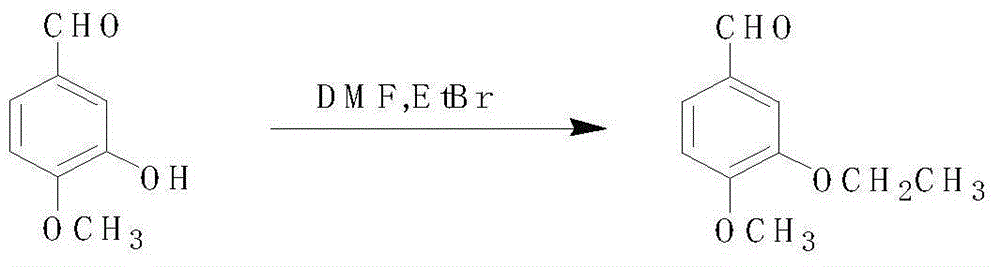

[0023] Put 0.5mol potassium carbonate, 0.5mol isovanillin and 100ml DMF into the reaction flask, stir and heat to 80°C, then slowly add 0.6mol (1.2eq) of bromoethane dropwise, and keep warm until the reaction of the raw materials is completed. Dissolving, extracting, concentrating, and drying to obtain 0.5 mol of white solid 3-ethoxy-4-methoxybenzaldehyde, 1.2% moisture, 98.9% purity, and 98.8% yield.

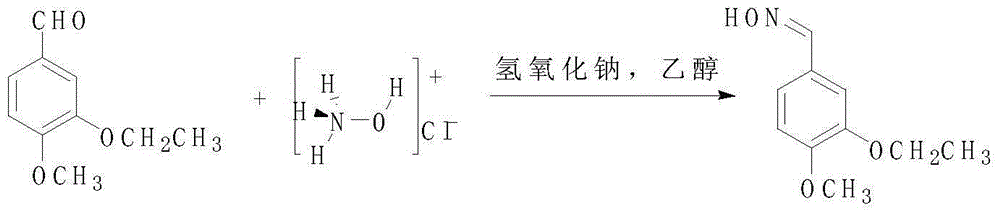

[0024] Drop into ethanol in reaction flask, hydroxylamine hydrochloride 0.6mol (1.5eq), sodium hydroxide 0.6mol (1.5eq) and above-mentioned 3-ethoxy-4-methoxybenzaldehyde 0.4mol that make, be warming up to 30- 40°C, heat-retaining reaction until the reaction of the raw materials is complete, add water to precipitate the product, and drain to obtain off-white solid 3-ethoxy-4-methoxybenzaldehyde oxime, dry 0.382mol, moisture 0.62%, purity 95.3%, yield 94.9%.

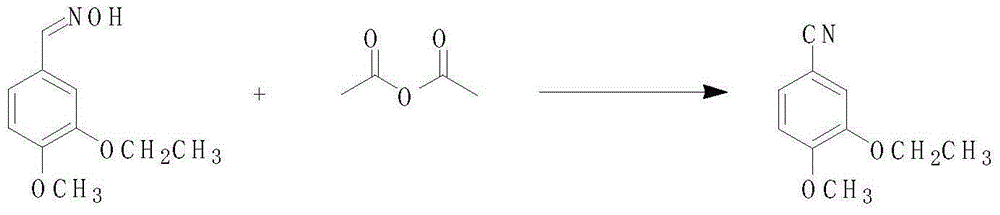

[0025] Put 1.05mol (3.5eq) of acetic anhydride and 0.3mol of the 3-ethoxy-4-methoxybenzaldehyde oxime prepared above in...

Embodiment 2

[0028] Put 0.5mol of potassium carbonate, 0.5mol of isovanillin and 100ml of DMF into the reaction bottle, stir and heat to 90°C, slowly add 0.5mol (1.0eq) of bromoethane dropwise, and keep the reaction until the raw materials are reacted , extraction, concentration, and drying to obtain 0.502mo of white solid 3-ethoxy-4-methoxybenzaldehyde, 1.3% moisture, 99.7% purity, and 99.1% yield.

[0029] Drop into ethanol, hydroxylamine hydrochloride 0.4mol (1.0eq) in reaction bottle, sodium hydroxide 0.4mol (1.0eq), the above-mentioned 3-ethoxy-4-methoxybenzaldehyde 0.4mol that makes, be warming up to 30- 40°C, keep warm until the reaction of the raw materials is complete, add water to precipitate the product, and drain to obtain off-white solid 3-ethoxy-4-methoxybenzaldehyde oxime, dry 0.368mol, moisture 0.5%, purity 94.2%, yield 91.5%.

[0030] Put 0.9 mol (3.0 eq) of acetic anhydride and 0.3 mol of the 3-ethoxy-4-methoxybenzaldehyde oxime prepared above into the reaction flask, he...

Embodiment 3

[0033] Put 0.5mol of potassium carbonate, 0.5mol of isovanillin and 100ml of DMF into the reaction bottle, stir and heat to 100°C, slowly add 0.75mol (1.5eq) of bromoethane dropwise, and keep the reaction until the raw materials are reacted Extraction, concentration, and pumping to dryness gave 0.498 mol of white solid 3-ethoxy-4-methoxybenzaldehyde, 1.1% moisture, 98.7% purity, and 98.5% yield.

[0034] Drop into ethanol, hydroxylamine hydrochloride 0.48mol (1.2eq) in reaction flask, sodium hydroxide 0.48mol (1.2eq), the above-mentioned 3-ethoxyl-4-methoxybenzaldehyde 0.4mol that makes is heated up to 30- 40°C, heat-retaining reaction, until the reaction of the raw materials is complete, add water to precipitate the product, and drain to obtain off-white solid 3-ethoxy-4-methoxybenzaldehyde oxime, dry 0.38mol, moisture 0.52%, purity 94.8%, yield 94.5%.

[0035] Put 1.2mol (4.0eq) of acetic anhydride and 0.3mol of the 3-ethoxy-4-methoxybenzaldehyde oxime prepared above into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com