Clopyralid salt active compound, preparation method for water-soluble granules of clopyralid salt active compound and applications

A technology of dichloropyridine salt and dichloropyridine acid, applied in the field of pesticide chemical industry, can solve the problems of easy dusting of soluble powder, low utilization rate of water-dispersible granules, environmental and human harm, etc., and meet the requirements of low cost and equipment Low, good safety and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

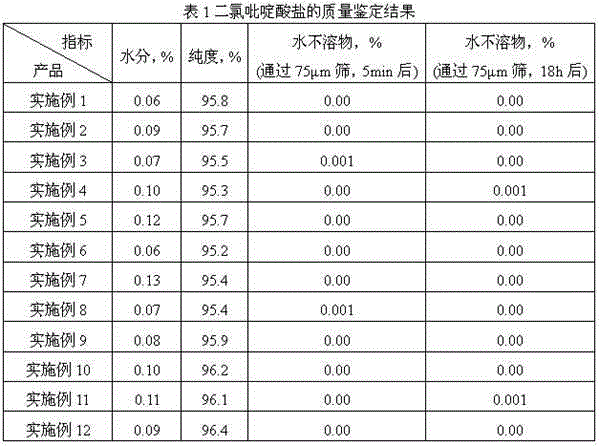

[0031] The preparation of embodiment 1 clopyralid potassium salt

[0032] In a 1L kneader with a heating device, put 400g of clopyralid (purity 95%) and 202g potassium bicarbonate (purity 99%) together, mix and stir under normal temperature and pressure at a speed of 60rpm 10 minutes, then heat up to 60°C, control the stirring speed to 40rpm, continue mixing at this temperature and stirring speed, detect the reaction degree of the material in about 1 hour, it shows that the reaction system has changed from the original drug of clopyralid which is insoluble in water to complete The clopyralid potassium salt technical drug dissolved in water, the prepared clopyralid potassium salt technical drug was dried at 80° C. to obtain 475 g of dry product, the analyzed content was 95.8%, and the yield was 99.8%.

Embodiment 2 2

[0033] The preparation of embodiment 2 clopyralid potassium salt

[0034] In a 1L kneader with a heating device, put 430g of clopyralid (purity 95%) and 121g of potassium hydroxide (purity 99%) together, mix and stir at 80rpm under normal temperature and pressure conditions After 15 minutes, the temperature was raised to 70°C, the stirring speed was controlled to 40rpm, and the mixing was continued at this temperature and stirring speed, and the degree of reaction of the materials was detected in about 1 hour, which showed that the reaction system changed from the original drug of clopyralid which was insoluble in water to complete The clopyralid potassium salt technical drug dissolved in water, the prepared clopyralid potassium salt technical drug was dried at 85° C. to obtain 510 g of dry product, the analyzed content was 95.7%, and the yield was 99.9%.

Embodiment 3 2

[0035] The preparation of embodiment 3 clopyralid potassium salt

[0036] In a 1L kneader with a heating device, 450g of clopyralid (purity 95%) and 158g of potassium carbonate (purity 99%) were put in together, and mixed and stirred at a speed of 70rpm for 12 Minutes, then heat up to 60°C, control the stirring speed to 50rpm, continue mixing at this temperature and stirring speed, detect the reaction degree of the materials in about 1 hour, it shows that the reaction system changes from the original drug of clopyralid which is insoluble in water to completely soluble The clopyralid potassium salt technical drug in water, the prepared clopyralid potassium salt technical drug was dried at 80° C. to obtain 535 g of dry product, the analyzed content was 95.5%, and the yield was 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com