Method for preparing Yunnan pine bark procyanidine

A bark proanthocyanidin and proanthocyanidin technology, which is applied in the field of extraction and purification of Yunnan pine bark proanthocyanidin preparation, can solve the problems of insufficient extraction efficiency and single means, and achieve the effects of simple and easy operation, accelerated mass transfer process, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

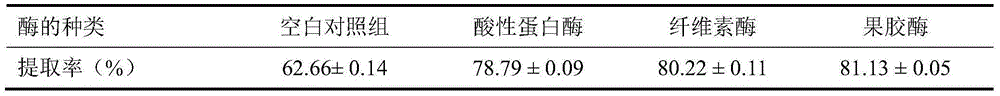

[0066] Embodiment 1, the influence of different enzymes on the extraction rate of proanthocyanidins from Yunnan pine bark

[0067] 1) Pulverize the bark of pine bark after cleaning and removing impurities, pass through a 60-mesh sieve, and add normal temperature water as an extraction solvent. The enzyme is one of acid protease (pepsin), cellulase or pectinase, and 1g of acid protease with enzyme activity of 1500U / mg or 1g of enzyme activity of 0.8 U / mg of cellulase or 1g of pectinase with an enzyme activity of 1.0U / mg. The pH of the mixed solution after adding the enzyme was adjusted to 3.5, and placed in a water bath constant temperature oscillator at 45° C. for 120 min to obtain an enzymatic hydrolysis solution. No enzyme was added to the blank control group, and other conditions remained unchanged.

[0068] 2) Centrifuge the mixed solution after enzymolysis in step 1) at a centrifugal force of 4000g-6000g (specifically 5000g) for 10min-30min (specifically 15min) to obtai...

Embodiment 2

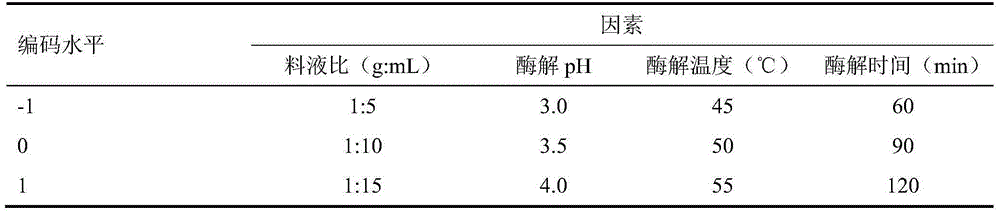

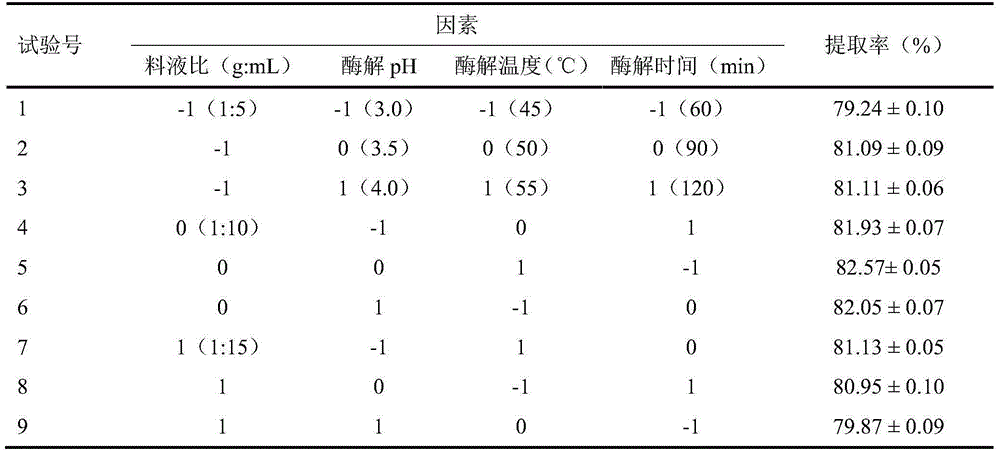

[0073] Embodiment 2, the influence of enzymolysis conditions on the extraction rate of proanthocyanidins from Yunnan pine bark

[0074] 1) Crush the bark of pine bark after cleaning and removing impurities, pass through a 60-mesh sieve, add room temperature water as an extraction solvent, and then add enzymes, add 1 g of enzymes to every 100 g of raw materials (crushed pine bark), the activity of which is 1.0 U / mg of pectinase, carry out enzymatic hydrolysis under certain conditions to obtain enzymatic hydrolyzate. According to the author's research, four factors, such as solid-liquid ratio, enzymatic hydrolysis pH, enzymatic hydrolysis temperature and enzymatic hydrolysis time, which have a great influence on the extraction rate of proanthocyanidins were selected for L 9 (3 4 ) orthogonal experiment, the designed four-factor three-level code is shown in Table 2, that is: the solid-liquid ratio of crushed Yunnan pine bark and normal temperature water is 1g: 5mL, 1g: 10mL or ...

Embodiment 3

[0082] Embodiment 3, the impact of high-voltage pulsed electric field treatment pulse number on the extraction rate of proanthocyanidins from Yunnan pine bark

[0083] 1) Crush the bark of Pine yunnanensis after cleaning and removing impurities, pass through a 60-mesh sieve, add normal temperature water as the extraction solvent, the ratio of solid to liquid between the bark of pine yunnanensis after crushing and clean water at normal temperature is 1g: 10mL, and then add enzyme, every 100g Add 1 g of pectinase with an enzyme activity of 1.0 U / mg to the raw material (crushed Yunnan pine bark). The pH of the mixed solution after adding the enzyme was adjusted to 3.5, and placed in a water bath constant temperature oscillator at 55° C. for 60 min to obtain an enzymatic solution.

[0084] 2) Homogenize the enzymolysis solution obtained in step 1) with a rubber mill for 15min-30min (specifically 20min), pump the mixed solution after the homogenized rubber mill into a high-voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com