Method for preparing anti-ultraviolet emulsion

An anti-ultraviolet and ultraviolet technology, applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve problems such as volatile, insufficient heat resistance, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

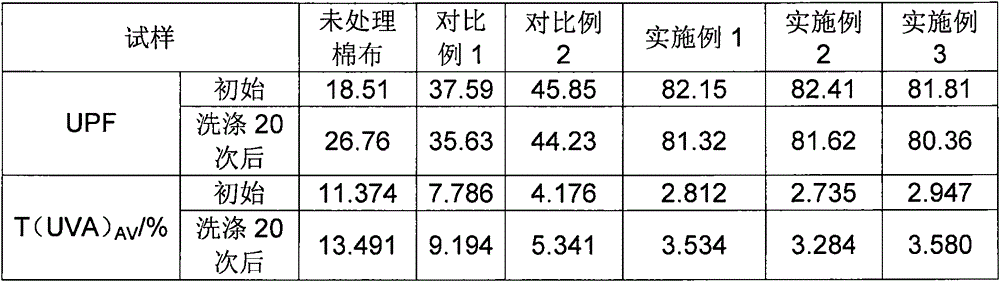

Examples

preparation example Construction

[0014] The invention discloses a preparation method of an anti-ultraviolet emulsion, comprising the following steps:

[0015] Firstly, the nano-titanium dioxide is surface-treated, and then the surface-treated nano-titanium dioxide, acrylate monomer, fluorine-containing monomer, emulsifier, deionized water, initiator, and polymerized ultraviolet absorber are mixed for emulsion polymerization to obtain Anti-UV lotion.

[0016] Nano-titanium dioxide has small particle size, high surface energy, strong polarity, is in a thermodynamically unstable state, and is easily agglomerated. In aqueous media, nanomaterials with high surface energy and specific surface area can strongly adsorb water and other media, and react to form R-OH group structures, which increase the interaction force between nanomaterials and the surface activity of materials; at the same time, the R-OH It is easy to polymerize or generate new linkers, which leads to the aggregation of nanomaterials and slurries, w...

Embodiment 1

[0039] A preparation method of an anti-ultraviolet emulsion, each component is measured in parts by mass, and the specific steps are:

[0040] Step 1. Surface pretreatment of nano-titanium dioxide:

[0041]Add 12 parts of nano-titanium dioxide and 600mL of absolute ethanol into the reaction flask, ultrasonically oscillate for 20min and then raise the temperature to 70°C, mix 5 parts of silane coupling agent, 3 parts of heptadecanylfluorodecyltrimethoxysilane and 50mL of absolute ethanol into the reaction flask , slowly drop into the above reaction flask under stirring, react for 4 hours, dry and grind at 80°C to obtain modified nano-titanium dioxide particles; wherein, the silane coupling agent is γ-methacryloxypropyltrimethoxysilane ;

[0042] Step 2, the synthesis of anti-ultraviolet emulsion:

[0043] 1) Add 300 parts of deionized water and 7 parts of emulsifier into the beaker, then add 7 parts of surface pretreated nano-titanium dioxide, and ultrasonically disperse for ...

Embodiment 2

[0050] A preparation method of an anti-ultraviolet emulsion, each component is measured in parts by mass, and the specific steps are:

[0051] Step 1. Surface pretreatment of nano-titanium dioxide:

[0052] Add 12 parts of nano-titanium dioxide and 600mL of absolute ethanol into the reaction flask, ultrasonically oscillate for 20min and then raise the temperature to 70°C, mix 5 parts of silane coupling agent, 3 parts of heptadecanylfluorodecyltrimethoxysilane and 50mL of absolute ethanol into the reaction flask , slowly drop into the above reaction flask under stirring, react for 4 hours, dry and grind at 80°C to obtain modified nano-titanium dioxide particles; wherein, the silane coupling agent is vinyl tris (β-methoxyethoxy) silane ; Step 2, the synthesis of UV-resistant emulsion:

[0053] 1) Add 320 parts of deionized water and 9 parts of emulsifier into the beaker, then add 9 parts of surface pretreated nano-titanium dioxide, and ultrasonically disperse for 20 minutes to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com