Preparation method of colorless transparent polyimide film with low yellowness and high mechanical property

A technology of transparent polyimide and polyimide resin, applied in the field of polymer materials, can solve the problems of poor stability, unsuitable for mass addition of cellulose, compatibility limitation, etc., so as to eliminate internal stress and improve optical transparency. Sex, the effect of eliminating yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

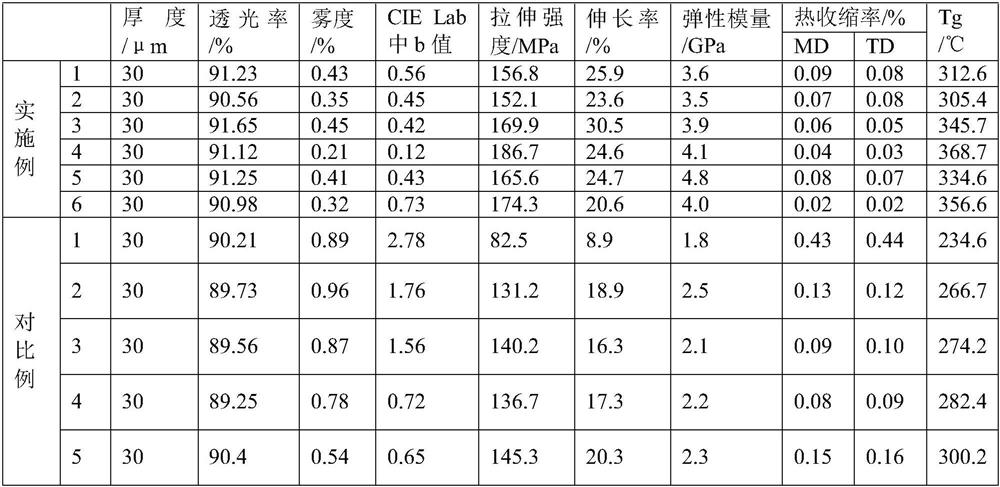

Examples

preparation example Construction

[0044] A preparation method of a colorless and transparent polyimide film with low yellowness and high mechanical properties, comprising the following steps:

[0045] (1) Dissolve alicyclic diamine in polar aprotic organic solvent A, add aminated nanocellulose (amino content is 1.3-1.8mmol / g, molecular weight is 5000-8000, diameter is 10-20nm, long 100-300nm), stirring continuously at 100-1500r / min for 5-20min, then adding alicyclic dianhydride in 2-10 times, stirring continuously for 5-24h at 0-10°C under nitrogen protection to obtain a polyamic acid solution. The molar ratio of the alicyclic diamine to the alicyclic dianhydride is 1.1-1:1-1.1, and the mass of the aminated nanocellulose is 1-10% of the alicyclic dianhydride. in:

[0046] Described cycloaliphatic diamine comprises 1,3-cyclohexanediamine, 1,4-cyclohexanediamine, 1,3-cyclobutanediamine, 4,4-diaminodicyclohexylmethane (PACM ) and one or more of 3,3-dimethyl-4,4-diaminodicyclohexylmethane (DMDC).

[0047] The c...

Embodiment 1

[0057] Add 11.4189g (0.1mol) of 1,4-cyclohexanediamine and 150g of N,N-dimethylacetamide (DMAC) into a 500mL three-necked flask equipped with a mechanical stirrer, a thermometer and a reflux condenser. Introduce nitrogen gas, and mechanically stir at 500 r / min for 20 min to obtain a clear solution. Then add 1.1209g of aminated nanocellulose (amino content is 1.3-1.8mmol / g, molecular weight is 5000-8000, diameter is 10-20nm, length is 100-300nm), continue to stir at 500r / min for 20min and divide into 5 times 22.4170 g (0.1 mol) of hydrogenated pyromellitic dianhydride (HPMDA) were added. Under the reaction condition of 5° C., stirring was continued at 500 r / min for 6 h to obtain a polyamic acid solution. Add 1.1209g carboxylated nanocellulose (carboxyl content is 1.2-3mmol / g, molecular weight is 5000-8000, diameter is 10-20nm, length is 100-300nm), 0.5g pyridine and 0.5g Acetic anhydride, continue stirring at 500 r / min for 6 h under nitrogen protection and reaction conditions...

Embodiment 2

[0060] The specific operations and conditions of Example 2 are the same as in Example 1, except that the used alicyclic diamine and alicyclic dianhydride are replaced by 1,3-cyclobutanediamine and 1,2,3,4-cyclobutanediamine respectively. Butane tetracarboxylic dianhydride (CBDA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com