Antibacterial oil-stain-resistant polypropylene material and preparation method thereof

A polypropylene material, oil-resistant technology, applied in the field of polypropylene materials, can solve the problems of reducing the surface tension of polypropylene-based composite materials, without involving antibacterial effects, etc., to achieve improved stiffness and surface hardness, excellent surface tension, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

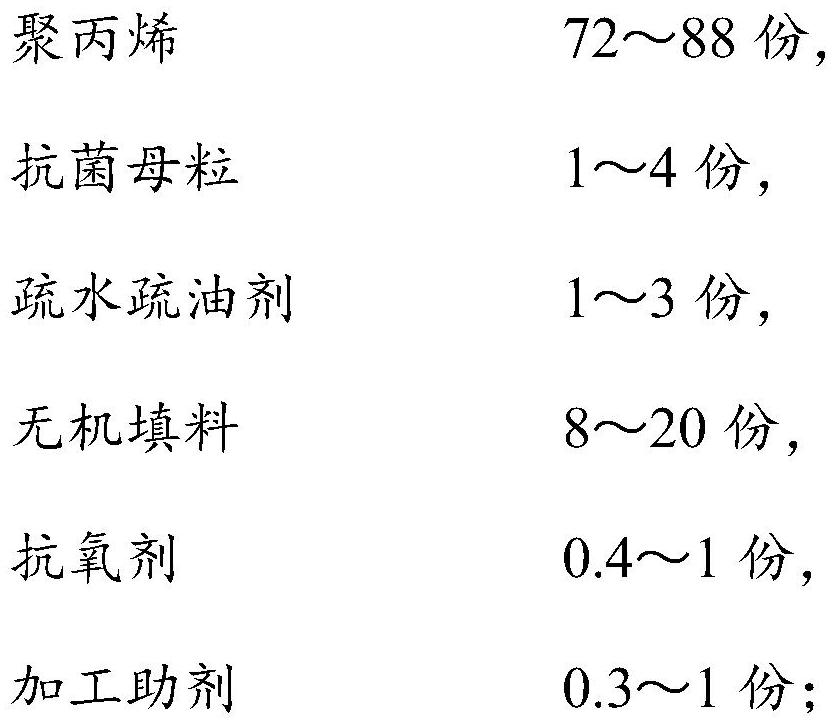

Method used

Image

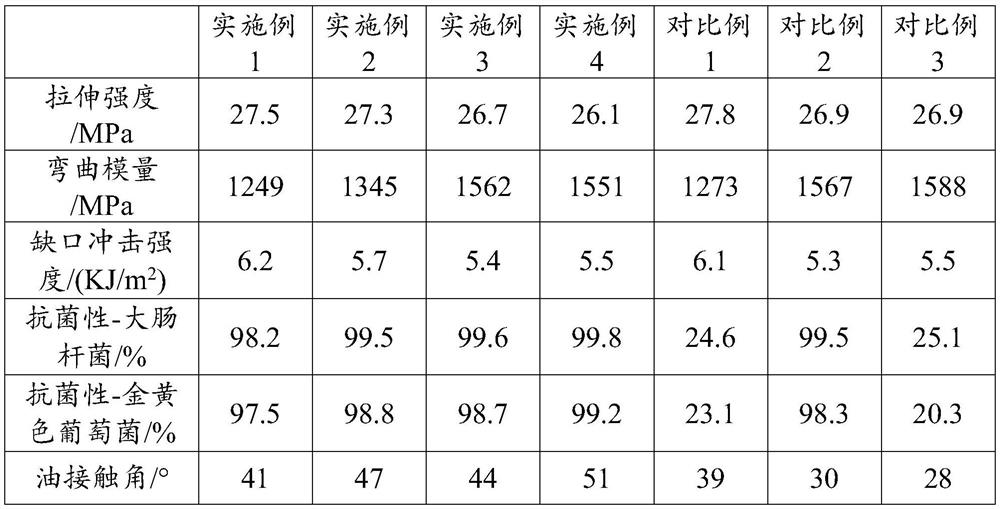

Examples

Embodiment 1

[0028] An antibacterial and oil-resistant polypropylene material, comprising the following raw materials in parts by weight: 87.2 parts of polypropylene, 1 part of antibacterial masterbatch, 1 part of hydrophobic and oleophobic agent, 10 parts of barium sulfate, 0.4 parts of antioxidant S2225, ultraviolet absorbing 0.3 part of agent, 0.1 part of dispersant;

[0029] Concrete preparation method comprises the following steps:

[0030] Add the polypropylene resin, antibacterial masterbatch, hydrophobic and oleophobic agent, inorganic filler, antioxidant and processing aid to a high-speed mixer and stir for 10 minutes to mix evenly, and then the premixed material is fed from the main feed of the twin-screw extruder Input into the mouth, the length-to-diameter ratio of the screw is 48:1, the screw speed is controlled within the range of 400r / min, the extrusion temperature is 200-220°C, the vacuum degree is -0.08MPa, after melting, extrusion, cooling and granulation, that is Antiba...

Embodiment 2

[0032] An antibacterial and oil-resistant polypropylene material, comprising the following raw materials in parts by weight: 79.7 parts of polypropylene, 2 parts of antibacterial masterbatch, 2 parts of hydrophobic and oleophobic agent, 15 parts of barium sulfate, 0.6 parts of antioxidant S2222, 5 parts of ultraviolet absorber 0.5 parts of agent, 0.08 parts of lubricant, 0.12 parts of dispersant;

[0033] Concrete preparation method comprises the following steps:

[0034] Add the polypropylene resin, antibacterial masterbatch, hydrophobic and oleophobic agent, inorganic filler, antioxidant and processing aid to a high-speed mixer and stir for 10 minutes to mix evenly, and then the premixed material is fed from the main feed of the twin-screw extruder Input into the mouth, the length-to-diameter ratio of the screw is 48:1, the screw speed is controlled within the range of 400r / min, the extrusion temperature is 200-220°C, the vacuum degree is -0.08MPa, after melting, extrusion, ...

Embodiment 3

[0036] An antibacterial and oil-resistant polypropylene material, comprising the following raw materials in parts by weight: 74.8 parts of polypropylene, 2 parts of antibacterial masterbatch, 2 parts of hydrophobic and oleophobic agent, 20 parts of barium sulfate, 50.5 parts of antioxidant S222, ultraviolet absorbing 0.5 parts of agent, 0.08 parts of lubricant, 0.12 parts of dispersant;

[0037] Concrete preparation method comprises the following steps:

[0038] Add the polypropylene resin, antibacterial masterbatch, hydrophobic and oleophobic agent, inorganic filler, antioxidant and processing aid to a high-speed mixer and stir for 10 minutes to mix evenly, and then the premixed material is fed from the main feed of the twin-screw extruder Input into the mouth, the length-to-diameter ratio of the screw is 48:1, the screw speed is controlled within the range of 500r / min, the extrusion temperature is 210-230°C, the vacuum degree is -0.08MPa, after melting, extrusion, cooling, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com