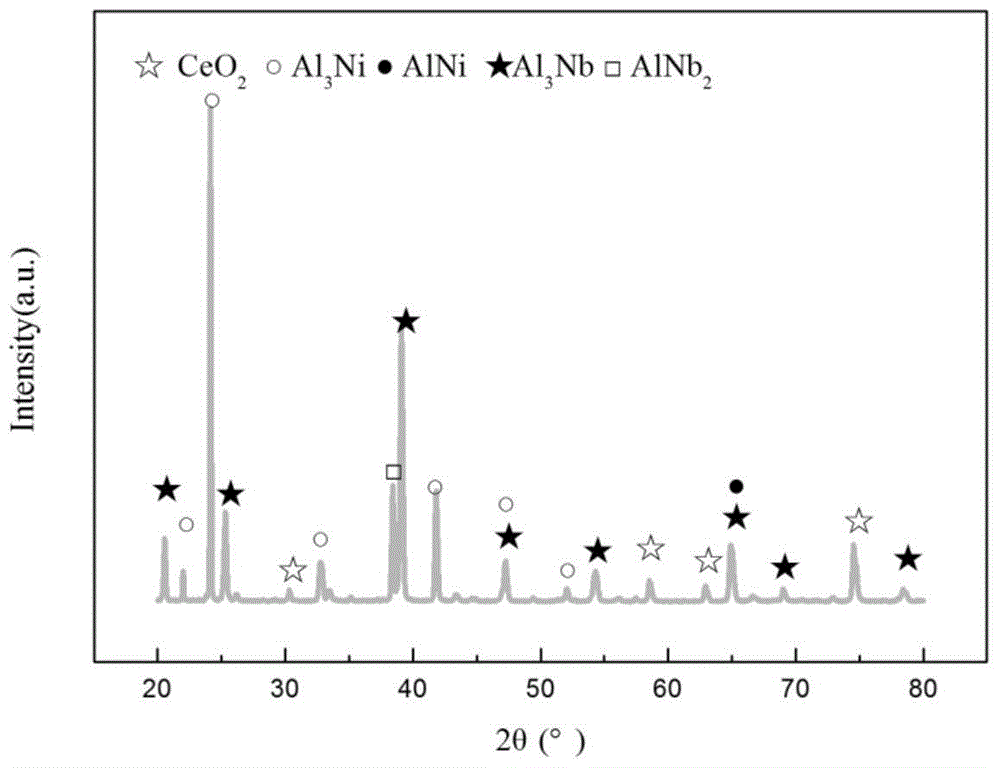

Method for preparing micrometer-particle-contained high-temperature-oxidation-resistant composite coating on surface of niobium alloy

A high-temperature oxidation-resistant, micro-particle technology, applied in metal material coating process, coating, superimposed layer plating, etc. Degradation, uniform and dense coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

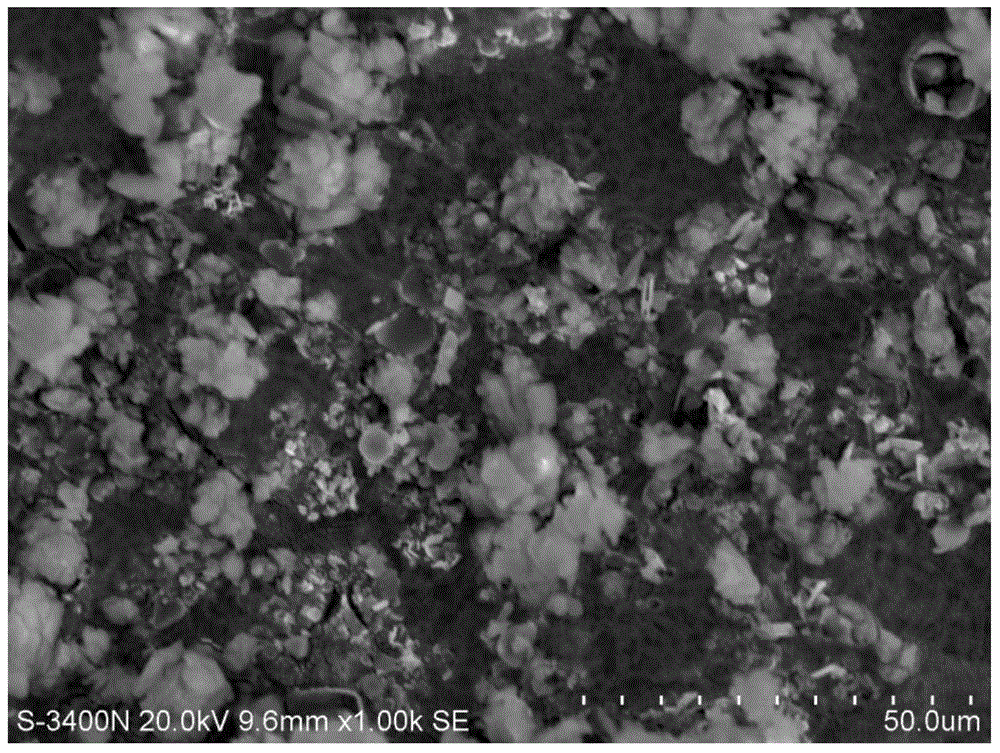

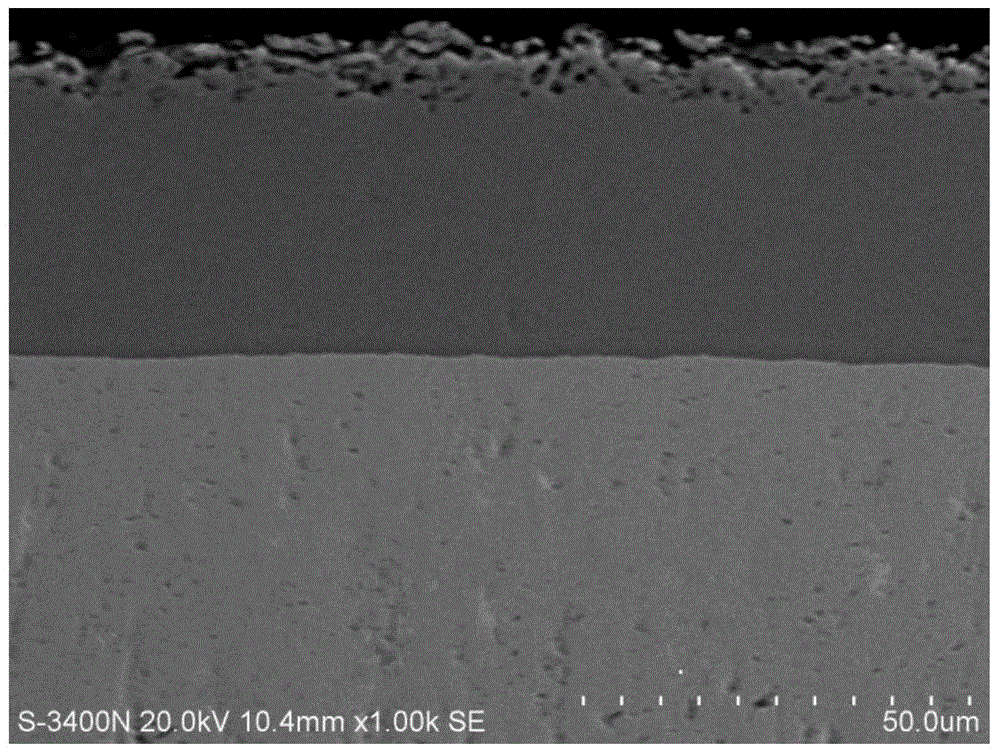

Examples

Embodiment 1

[0033] A method for preparing a high-temperature oxidation-resistant composite coating containing micron particles on the surface of a niobium alloy, comprising the following steps:

[0034] 1. Pretreatment: The base material is niobium alloy, and the base material is ultrasonically cleaned in acetone and absolute ethanol with a mass concentration of 99.9% respectively for 10 minutes, and dried;

[0035] 2. Coating pretreatment:

[0036] Substrates are pretreated in turn as follows:

[0037] Chemical degreasing, degreasing agent formula: 25g / LNa 3 PO 4 12H 2 O,30g / LNa 2 CO 3 , 10g / LNa 2 SiO 3 ;

[0038] Pickling, mixed acid proportioning is: water: sulfuric acid volume ratio=1:1, wherein sulfuric acid mass concentration is 95%;

[0039] One-time zinc dipping, the formula of zinc dipping solution is: 50g / LNaOH, 2g / LKNaC 4 h 4o 6 ·H 2 O,5g / LZnO,2g / LFeCl 3 ·6H 2 O,1g / LNaNO 3 ;

[0040] Zinc stripping, zinc stripping solution is water: nitric acid volume ratio=1:1...

Embodiment 2

[0051] 1, pretreatment is the same as embodiment 1.

[0052] 2. Coating pretreatment:

[0053] Substrates are pretreated in turn as follows:

[0054] Chemical degreasing is the same as in Example 1.

[0055] Pickling, mixed acid proportioning is: water: sulfuric acid volume ratio=1:1, wherein sulfuric acid concentration is 97%;

[0056] One-time galvanizing and two-time galvanizing are all the same as in Example 1.

[0057] Zinc stripping, zinc stripping solution is water: nitric acid volume ratio=1:1, wherein nitric acid mass concentration is 66%;

[0058] Wash with distilled water;

[0059] 3. Particle activation: the CeO 2 Micron particles are soaked in an alcohol solution with a mass concentration of 99.9%, and 2g / L of OP-21 is added to stir and soak. After the alcohol solution is clarified, pour off the alcohol solution and add deionized water to soak; soak in alcohol solution and deionized water for activation treatment 10 minutes each.

[0060] 4. Preparation of ...

Embodiment 3

[0066] 1, pretreatment is the same as embodiment 1.

[0067] 2. Coating pretreatment:

[0068] The samples were pretreated sequentially as follows:

[0069] Chemical degreasing is the same as in Example 1.

[0070] Pickling, mixed acid proportioning is: water: sulfuric acid volume ratio=1:1, wherein sulfuric acid concentration is 98%;

[0071] One-time galvanizing and two-time galvanizing are all the same as in Example 1.

[0072] Zinc stripping, zinc stripping solution is water: nitric acid volume ratio=1:1, wherein nitric acid mass concentration is 68%;

[0073] 3. Particle activation: the CeO 2 Micron particles are soaked in an alcohol solution with a mass concentration of 99.9%, and 2g / L of OP-21 is added to stir and soak. After the alcohol solution is clarified, pour off the alcohol solution and add deionized water to soak; soak in alcohol solution and deionized water for activation treatment 10 minutes each.

[0074] 4. Preparation of Ni-CeO 2 Plating:

[0075] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com