Passivated emitter region back surface partial diffused crystalline silicon solar cell preparation method

A solar cell, passivation emission technology, applied in the field of solar cells, can solve problems such as poor utilization of sunlight energy, low reflectivity, and decrease in reverse saturation current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

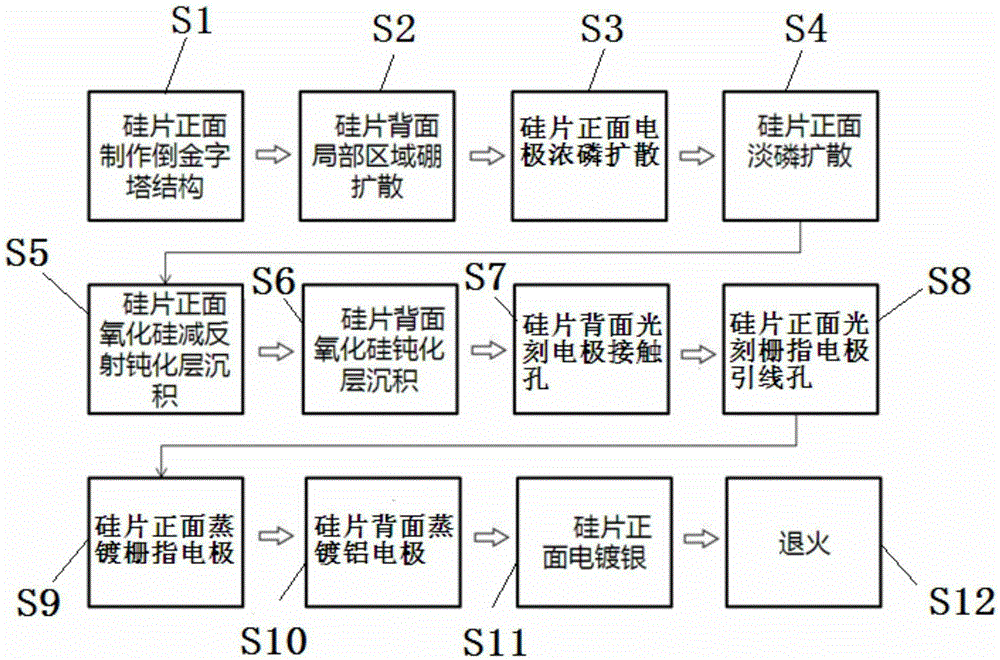

[0033] Such as figure 1 A method for preparing a partially diffused crystalline silicon solar cell on the back side of a passivated emission region comprises the following steps: step S1: making an inverted pyramid structure on the front side of the silicon wafer; step S2: diffusion of boron in a local area on the back side of the silicon wafer; step S3: silicon wafer Diffusion of concentrated phosphorus on the front electrode; step S4: light phosphorus diffusion on the front side of the silicon wafer; step S5: deposition of a silicon oxide anti-reflection passivation layer on the front side of the silicon wafer; step S6: deposition of a silicon oxide passivation layer on the back side of the silicon wafer; step S7: the back side of the silicon wafer Photoetching electrode contact holes; step S8: photoetching grid finger electrode lead holes on the front side of the silicon wafer; step S9: evaporating grid finger electrodes on the front side of the silicon wafer; step S10: evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com