Polymer solar battery based on solvent doping, and preparation method thereof

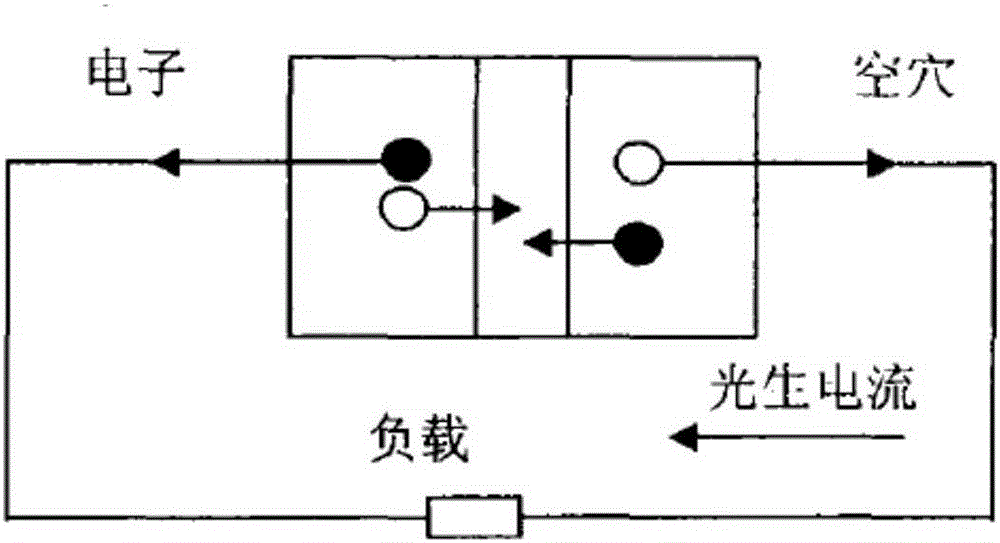

A solar cell and polymer technology, applied in the field of polymer solar cells based on solvent doping, can solve the problems of low carrier mobility and low light absorption efficiency, and achieve the effect of improving efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

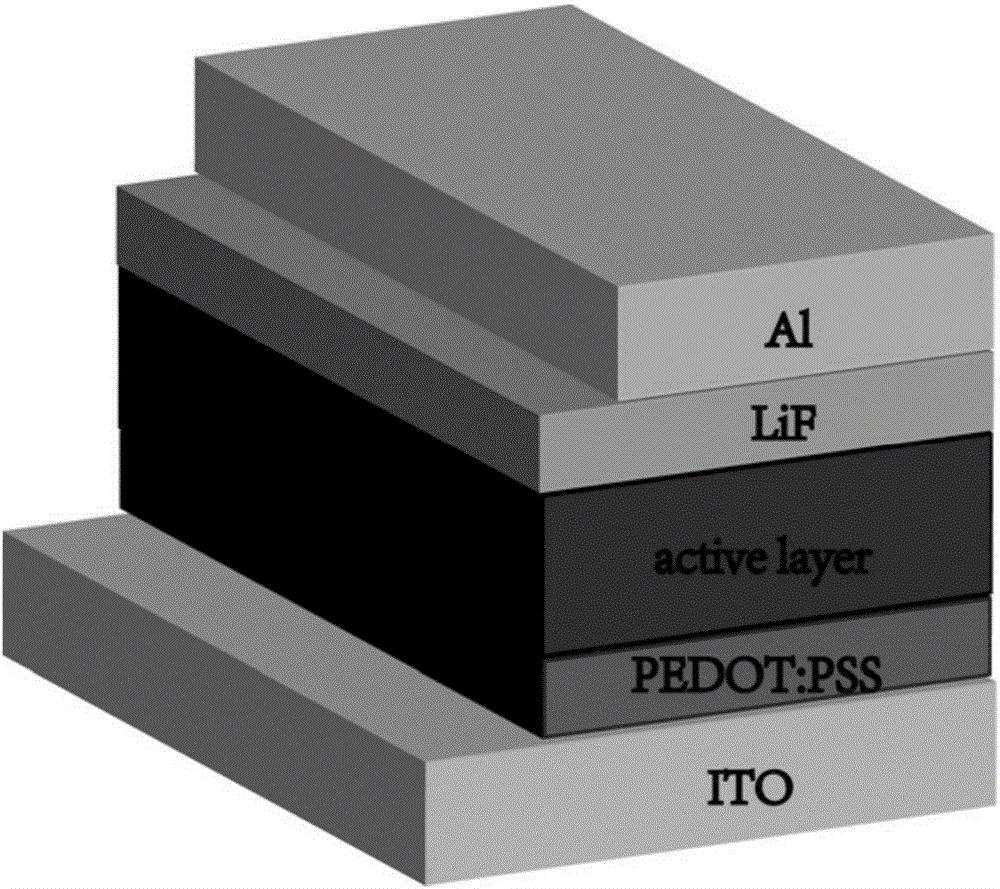

[0030] The polymer solar cell based on P3HT:PCBM system is provided in this embodiment, its structure is as follows figure 2 As shown, the glass substrate is followed by an anode electrode, a hole transport layer, an active layer, an electron transport layer, and a cathode; it is prepared by the following process:

[0031] 1. Prepare the mixed solution two days in advance. The mixed solution configuration process is as follows:

[0032] a. The volume of the mixed solvent is 1ml, including 0.95ml of o-dichlorobenzene and 0.05ml of 1-chloro-4-pentylbenzene, that is, the volume ratio of 1-chloro-4-pentylbenzene to the total solvent is 5%;

[0033] b. Weigh 20mgP3HT and 20mgPCBM and dissolve in the mixed solvent;

[0034] c. The mixed solution was stirred and heated for 48 hours;

[0035] 2. The anode is indium tin oxide (ITO), and its square resistance is 15Ω / cm 2 . Wash the ITO with a special ITO cleaning agent, rinse it with deionized water, and then dry it in an oven for ...

Embodiment 2

[0044] In this embodiment, a polymer solar cell based on the P3HT:PCBM system is provided, and the solvent additive in the active layer mixed material solution is 1-bromo-4-pentylbenzene. During the preparation process, 0.99ml of Chlorobenzene, 0.01ml 1-bromo-4-pentylbenzene, that is, 1-bromo-4-pentylbenzene accounts for 1% of the total solvent volume.

[0045] The performance parameters of the polymer solar cell in the present embodiment tested under the same conditions are shown in the following table:

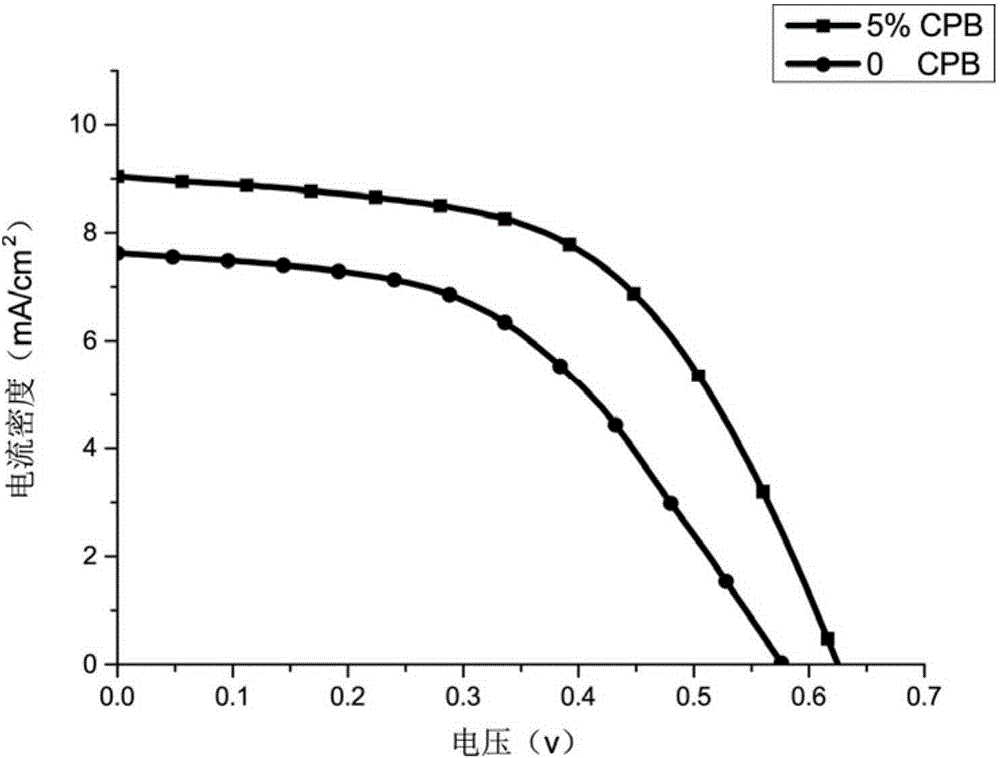

[0046] add ratio

[0047] It can be seen from the table that the efficiency of the device of the present invention is significantly improved compared with that of the original device. Adding 1% 1-bromo-4-pentylbenzene in the mixed solution of the active layer increases the open-circuit voltage to a certain extent, and the short-circuit current increases from 7.62mA / cm 2 increased to 10.94mA / cm 2 , the final conversion efficiency increased by 41.7%. I-V curve such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com