Preparation method of shepherd's-purse edible film

A technology of shepherd's purse and mixed slurry, which is applied in food preparation, sustainable manufacturing/processing, food science and other directions, can solve problems such as low utilization rate, and achieve the effects of convenient operation, good social and economic benefits, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

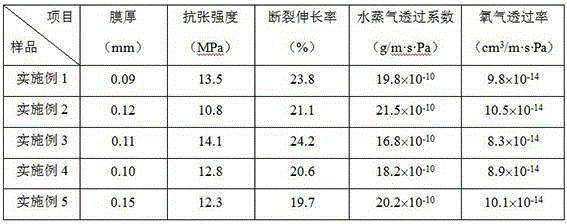

Examples

Embodiment 1

[0025] A preparation method of shepherd's purse edible film, comprising the following steps:

[0026] (1) Pretreatment of shepherd's purse: select fresh shepherd's purse, remove rotten leaves, withered yellow leaves, keep the roots, and clean them;

[0027] (2) Color protection treatment: cut the shepherd's purse washed in step (1) into 1cm long sections, and boil it with 0.2% Na 2 SO 3 After blanching in the solution for 3 minutes, remove and drain;

[0028] (3) Pulping: mashing the shepherd's purse after draining in step (2) into a shepherd's purse pulp with a tissue masher, and then refining the shepherd's purse pulp with a colloid mill to obtain a shepherd's purse pulp with an average particle size of 100 μm;

[0029] (4) Preparation of thickener mixture: Add tapioca starch into water, the mass fraction of which is 1.0%; bathe in water at 85°C for 90 minutes to obtain tapioca starch paste, then add fish skin gelatin, and fully dissolve to obtain Thickener mixed solution...

Embodiment 2

[0034] A preparation method of shepherd's purse edible film, comprising the following steps:

[0035] (1) Pretreatment of shepherd's purse: select fresh shepherd's purse, remove rotten leaves, withered yellow leaves, keep the roots, and clean them;

[0036] (2) Color protection treatment: cut the shepherd's purse washed in step (1) into 1.5cm long sections, and boiled with 0.5% Na 2 SO 3 After blanching in the solution for 1.5 minutes, remove and drain;

[0037] (3) Pulping: mashing the shepherd's purse after draining in step (2) into a shepherd's purse pulp with a tissue masher, and then refining the shepherd's purse pulp with a colloid mill to obtain a shepherd's purse pulp with an average particle size of 100 μm;

[0038] (4) Preparation of thickener mixture: Add tapioca starch into water, the mass fraction of which is 1.5%; bathe in water at 90°C for 80 minutes to obtain tapioca starch paste, then add fish skin gelatin, and fully dissolve to obtain Thickener mixed solut...

Embodiment 3

[0043] A preparation method of shepherd's purse edible film, comprising the following steps:

[0044] (1) Pretreatment of shepherd's purse: select fresh shepherd's purse, remove rotten leaves, withered yellow leaves, keep the roots, and clean them;

[0045] (2) Color protection treatment: cut the shepherd's purse washed in step (1) into 2cm long segments, and use boiled 0.4% Na 2 SO 3 After blanching in the solution for 1 min, remove and drain;

[0046] (3) Pulping: mashing the shepherd's purse after draining in step (2) into a shepherd's purse pulp with a tissue masher, and then refining the shepherd's purse pulp with a colloid mill to obtain a shepherd's purse pulp with an average particle size of 100 μm;

[0047] (4) Preparation of thickener mixture: add tapioca starch into water, the mass fraction of which is 2.0%; bathe in water at 80°C for 90 minutes to obtain tapioca starch paste, then add fish skin gelatin, and dissolve fully to obtain Thickener mixed solution, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com