Preparation method of acid-reduction solid actinidia chinensis planch fruit granule drink

A technology of kiwi fruit and kiwi fruit is applied in the field of beverage preparation, which can solve the problems of acidity and the like, and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

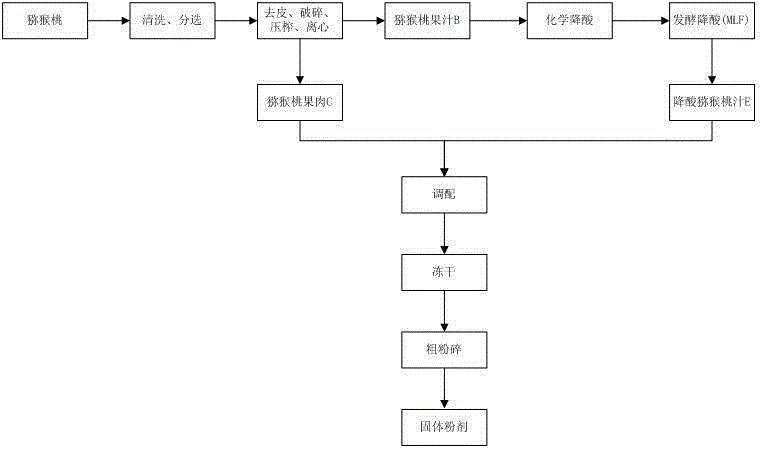

Method used

Image

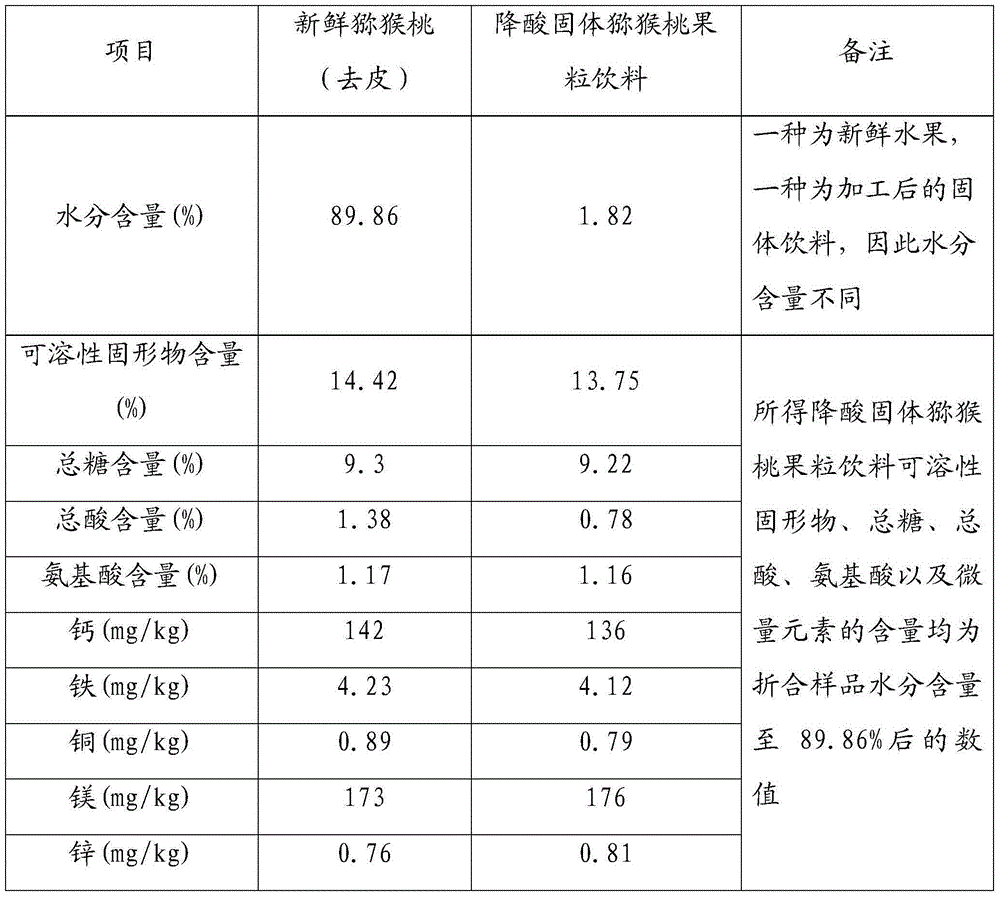

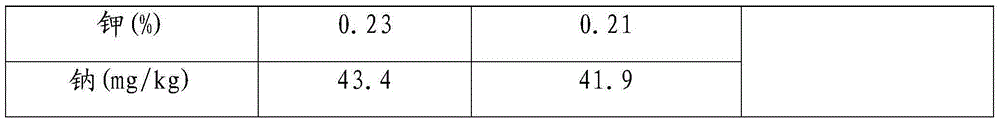

Examples

Embodiment 1

[0017] Fresh kiwi fruit is washed, sorted, peeled, crushed, and squeezed to obtain kiwi fruit juice A. After kiwi fruit juice A is centrifuged to obtain kiwi fruit juice B and kiwi fruit pulp C, the centrifugal speed is 3000r / min. The pH value is 2.9, and the pH value of the fruit juice D obtained after the chemical reduction of acid is 4.0 after being adjusted by 0.8mol / L sodium bicarbonate solution, then the fruit juice D is sterilized and cooled at 121°C, and then inserted into Lactobacillus plantarum No.: SICC1.372), the inoculum size is 10 8 CFU / g, malolactic-lactic fermentation (MLF, 48h) occurs at a temperature of 25°C, so that the pH value of the fermented and acid-reduced fruit juice E is 4.8. The ratio is fully mixed and evenly prepared, freeze-dried and coarsely crushed to obtain kiwi fruit solid powder (ie, acid-reduced solid kiwi fruit drink).

Embodiment 2

[0019] Fresh kiwi fruit is cleaned, sorted, peeled, crushed, and squeezed to obtain kiwi fruit juice A. After kiwi fruit juice A is centrifuged to obtain kiwi fruit juice B and kiwi fruit pulp C, the centrifugal speed is 3600r / min. The pH value is 3.2, and the pH value of the fruit juice D obtained after the chemical acid reduction is 3.9 after being regulated by 0.5mol / L sodium bicarbonate solution, then after the fruit juice D is sterilized and cooled at 121°C, it is inserted into Lactobacillus plantarum No.: SICC1.372), the inoculum size is 10 9 CFU / g, malolactic fermentation (MLF, 36h) occurs at a temperature of 25°C, so that the pH value of the fermented and acid-reduced fruit juice E is 4.7. The ratio is fully mixed and evenly prepared, freeze-dried and coarsely crushed to obtain kiwi fruit solid powder (ie, acid-reduced solid kiwi fruit drink).

Embodiment 3

[0021] Fresh kiwi fruit is washed, sorted, peeled, crushed, and squeezed to obtain kiwi fruit juice A. After kiwi fruit juice A is centrifuged to obtain kiwi fruit juice B and kiwi fruit pulp C, the centrifugal speed is 4000r / min. The pH value is 3.0, and the pH value of the fruit juice D obtained after the chemical acid reduction is 3.8 after being adjusted by 0.7mol / L sodium bicarbonate solution, and then the fruit juice D is sterilized and cooled at 121°C, and then inserted into Lactobacillus plantarum No.: SICC1.372), the inoculum size is 10 9 CFU / g, malic acid-lactic acid fermentation (MLF, 40h) occurs at a temperature of 25°C, thereby obtaining a pH value of 4.6 in the fermented and acid-reduced fruit juice E. The ratio is fully mixed and evenly prepared, freeze-dried and coarsely crushed to obtain kiwi fruit solid powder (ie, acid-reduced solid kiwi fruit drink).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com