Method for comprehensively utilizing yellow phosphorus tail gas

A yellow phosphorus tail gas and gas technology, applied in separation methods, chemical instruments and methods, using solid contact hydrogen separation, etc., can solve problems such as the complex composition of yellow phosphorus tail gas, reduce operating costs, reduce production costs, and significantly reduce social costs. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A factory produces yellow phosphorus by-product yellow phosphorus tail gas 63000Nm 3 / h, gas composition: 86.3% CO, 5.1% H 2 , 0.5% O 2 , 2%CO 2 , 0.2%CH 4 , containing trace impurity H 2 S500ppm, organic sulfur 2ppm, cyanide 30ppm, arsenide 0.7ppm, phosphide 600ppm, fluoride 0.4ppm, chloride 0.8ppm, metal carbonyl 1ppm, the rest is N 2 . The method of described dephosphorization is to use adsorption method dephosphorization to make pH 3 content 3 <0.1ppm.

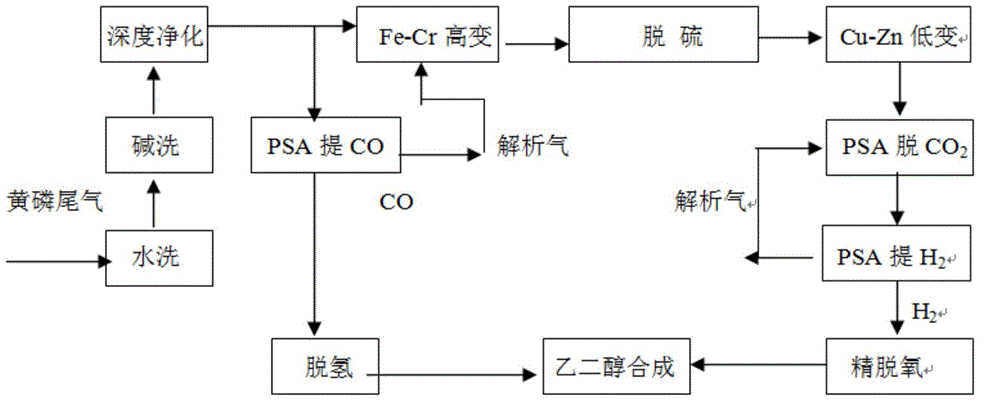

[0032] Such as figure 1As shown, after the yellow phosphorus tail gas is washed with water and alkali, it is composed of commercially available industrial fine desulfurizers, dephosphorization agents, arsenic removal agents, defluorination agents, dechlorination agents, decarbonylation metal catalysts, HCN removal catalysts, and deoxidizers. The deep purification section removes the impurity content in the tail gas to H 2 S2 3 3 2 <200ppm. The removal of phosphorus adopts the method of adsorption plus cata...

Embodiment 2

[0037] A factory produces yellow phosphorus by-product yellow phosphorus tail gas 40000Nm 3 / h, gas composition: 83.1% CO, 7.8% H 2 , 0.3% O 2 , 1.8%CO 2 , 0.4%CH 4 , containing trace impurity H 2 S380ppm, organic sulfur 2.6ppm, cyanide 20ppm, arsenide 0.9ppm, phosphide 560ppm, fluoride 0.3ppm, chloride 0.5ppm, metal carbonyl 1ppm, the rest is N 2 . The method of described dephosphorization is to use adsorption method dephosphorization to make pH 3 content 3 <0.1ppm.

[0038] Such as figure 1 As shown, after the yellow phosphorus tail gas is washed with water and alkali, it is composed of commercially available industrial fine desulfurizers, dephosphorization agents, arsenic removal agents, defluorination agents, dechlorination agents, decarbonylation metal catalysts, HCN removal catalysts, and deoxidizers. The deep purification section removes the impurity content in the tail gas to H 2 S2 3 3 2 <200ppm. The removal of phosphorus adopts the method of adsorption plus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com