Application of lithium niobate pyroelectric material in atmospheric particulate adsorption on basis of temperature control

A technology of atmospheric particulate matter and lithium niobate, applied in the direction of electrostatic effect separation, electrode cleaning, electrostatic separation, etc., can solve the problems of reduced adsorption efficiency, complicated electrification process, and restrictions on the application of organic electret filter materials, and achieve wear resistance Effects of performance improvement and simplification of charging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

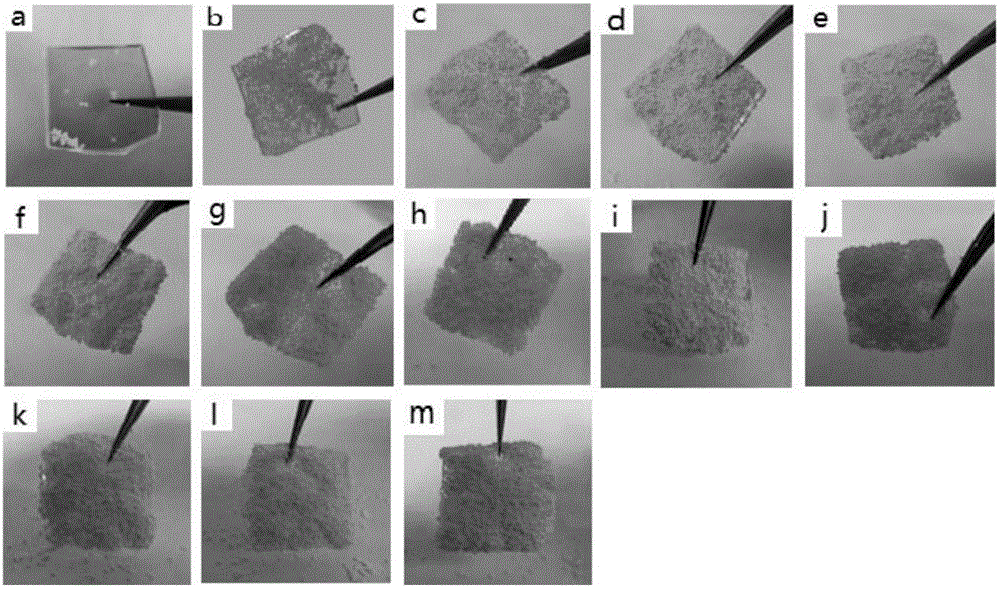

[0040] Embodiment 1, determination of optimum adsorption temperature of lithium niobate

[0041] The strength of the pyroelectric effect can be expressed by the pyroelectric coefficient. The formula for the change of polarization and the change of pyroelectric temperature is as follows: ΔP=pΔT (p is the pyroelectric coefficient, ΔT is the change of crystal temperature, and ΔP is the change of polarization). In principle, as long as there is a temperature difference, the surface of the lithium niobate material can be charged. Due to the large thickness of the lithium niobate wafer, the surface potential of the lithium niobate wafer cannot be directly characterized by the electrostatic force microscope. Therefore, the surface potential can be indirectly characterized by the amount of adsorption on the negatively charged PS balls at different temperatures, and the best Optimum pyroelectric temperature.

[0042] Cut the lithium niobate pyroelectric material into 13 small pieces ...

Embodiment 2

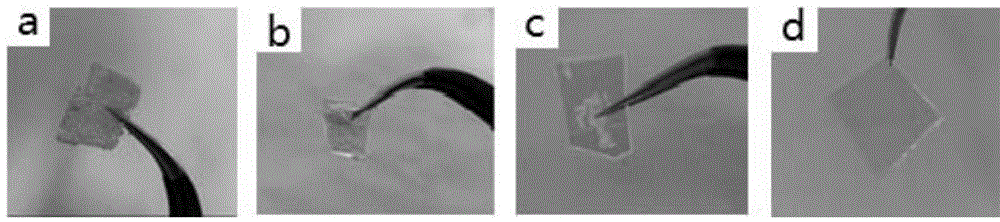

[0045] Embodiment 2, lithium niobate storage capacity

[0046] Cut several pieces of lithium niobate wafers with the same area (1cm×2cm), clean them, put them in a clean Petri dish, and put them in an oven at the same time. After heating to 100°C, take them out after the oven temperature drops to room temperature. Then take out one piece every 24 hours for adsorption experiment, and record and observe the change of adsorption amount. This method ensures that each piece of lithium niobate is naturally attenuated under the same initial conditions.

[0047] image 3 It is the adsorption graph of PS pellets on lithium niobate wafers with the same initial heating condition (100°C) after heating for 1h (the time for cooling to room temperature in the oven), 25h, 73h and 121h. Among them, Figures (a) to (d) correspond to the adsorption diagrams of lithium niobate wafers on PS pellets at 1h, 25h, 73h and 121h after heating, respectively.

[0048] It can be seen from the figure that ...

Embodiment 3

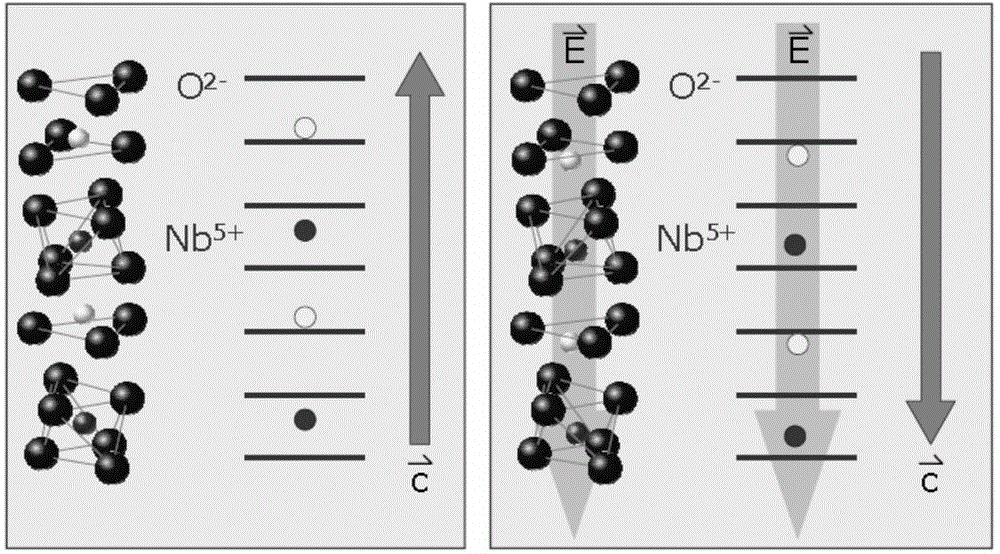

[0049] Embodiment 3, pyroelectric properties of lithium niobate wafer

[0050] Due to the large thickness of lithium niobate crystals, the surface charge generated by pyroelectricity cannot be characterized by the method of measuring the surface potential by atomic force. Therefore, the present invention uses lithium niobate for the adsorption of negatively charged polystyrene pellets Indirectly characterize its surface potential. Under different heating conditions, lithium niobate can adsorb PS pellets with a particle size of 300 μm.

[0051] Figure 4 It is the adsorption diagram of lithium niobate heated to different temperatures on PS pellets. Wherein, a, b, and c correspond to the temperatures of the heated lithium niobate being 100° C., 150° C. and 200° C., respectively.

[0052] It can be seen from the figure that the heated lithium niobate has a large amount of positive charge on the surface, has a strong Coulomb effect, and shows a strong adsorption effect on PS pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com