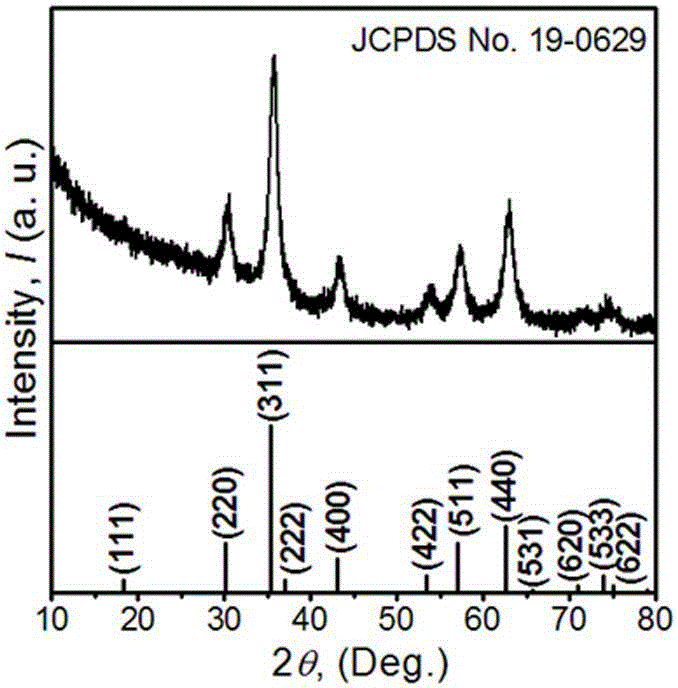

Method for preparing porous flower-shape-structured ferroferric oxide wave absorbing material

A technology of triiron tetroxide and flower-like structure, which is applied in the direction of iron oxide/iron hydroxide, ferrous iron oxide, etc., can solve the problems of toxicity, hazards, yields, etc., and achieve improved wave-absorbing performance, reduced material density, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) the anhydrous ferric chloride of 10mmol, i.e. FeCl 3 and 100mmol urea were added to 50ml of ethylene glycol solution, wherein the molar ratio of anhydrous ferric chloride and urea was 1:10, and the molar concentration of urea was 2.0mol / L, and mixed solution A was obtained after fully stirring and dissolving;

[0038](2) Put the mixed solution A described in step (1) into the reaction kettle, react at 220°C for 2 hours, wash and dry to obtain the granular precursor B;

[0039] (3) Under the protection of inert gas nitrogen, the granular precursor B obtained in step (2) is heated to 380° C. and kept for 5 hours, and then cooled to room temperature;

[0040] (4) a porous flower-like structure ferric oxide material, prepared by the above method, such as figure 2 shown.

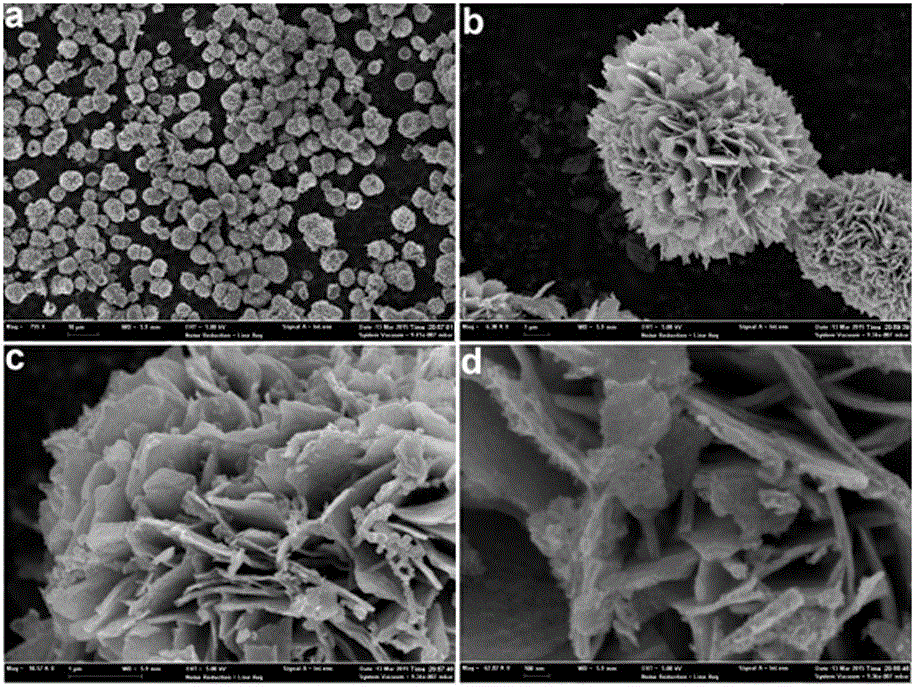

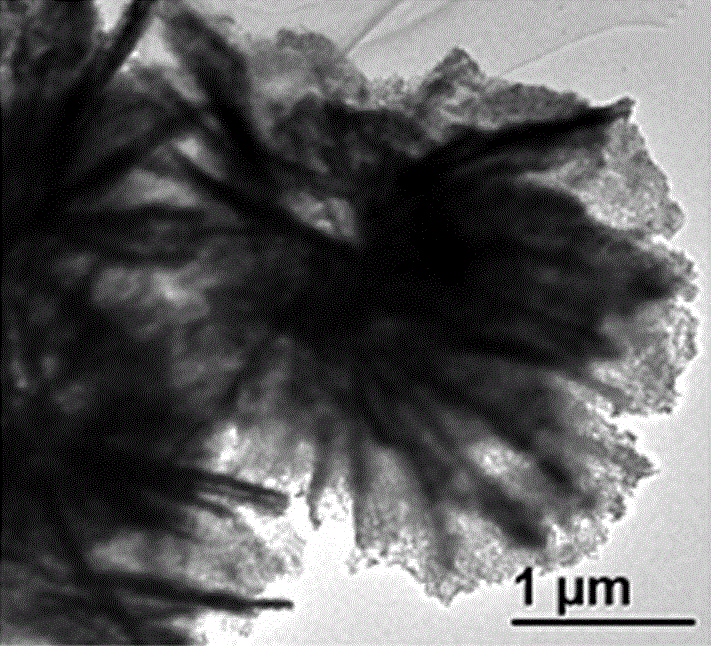

Embodiment 2

[0042] (1) the anhydrous ferric chloride of 10mmol, i.e. FeCl 3 And 160mmol urea is joined in the ethylene glycol solution of 100ml, wherein the molar ratio of anhydrous ferric chloride and urea is 1:16, and the molar concentration of urea is 1.6mol / L, obtain mixed solution A after fully stirring and dissolving;

[0043] (2) Put the mixed solution A described in step (1) into the reaction kettle, react at 200°C for 4 hours, wash and dry to obtain the granular precursor B;

[0044] (3) Under the protection of inert gas nitrogen, the granular precursor B obtained in step (2) is heated to 400°C and kept for 1.5h, and then cooled to room temperature;

[0045] (4) a porous flower-like structure ferric oxide material, prepared by the above method, such as Figure 3~6 shown.

Embodiment 3

[0047] (1) the anhydrous ferric chloride of 15mmol, i.e. FeCl 3 And 180mmol urea is added in the ethylene glycol solution of 100ml, wherein the molar ratio of anhydrous ferric chloride and urea is 1:12, and the molar concentration of urea is 1.8mol / L, obtain mixed solution A after fully stirring and dissolving;

[0048] (2) Put the mixed solution A described in step (1) into the reaction kettle, react at 180°C for 6 hours, wash and dry to obtain the granular precursor B;

[0049] (3) Under the protection of inert gas nitrogen, the granular precursor B obtained in step (2) was heated up to 450° C. and kept for 3 hours, and then cooled to room temperature.

[0050] (4) A ferric oxide material with a porous flower-like structure, which is prepared by the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com