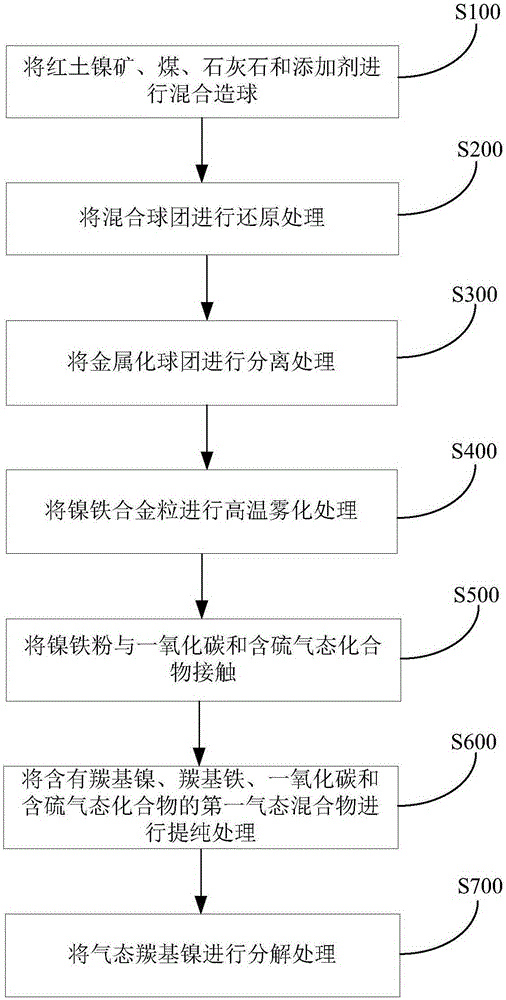

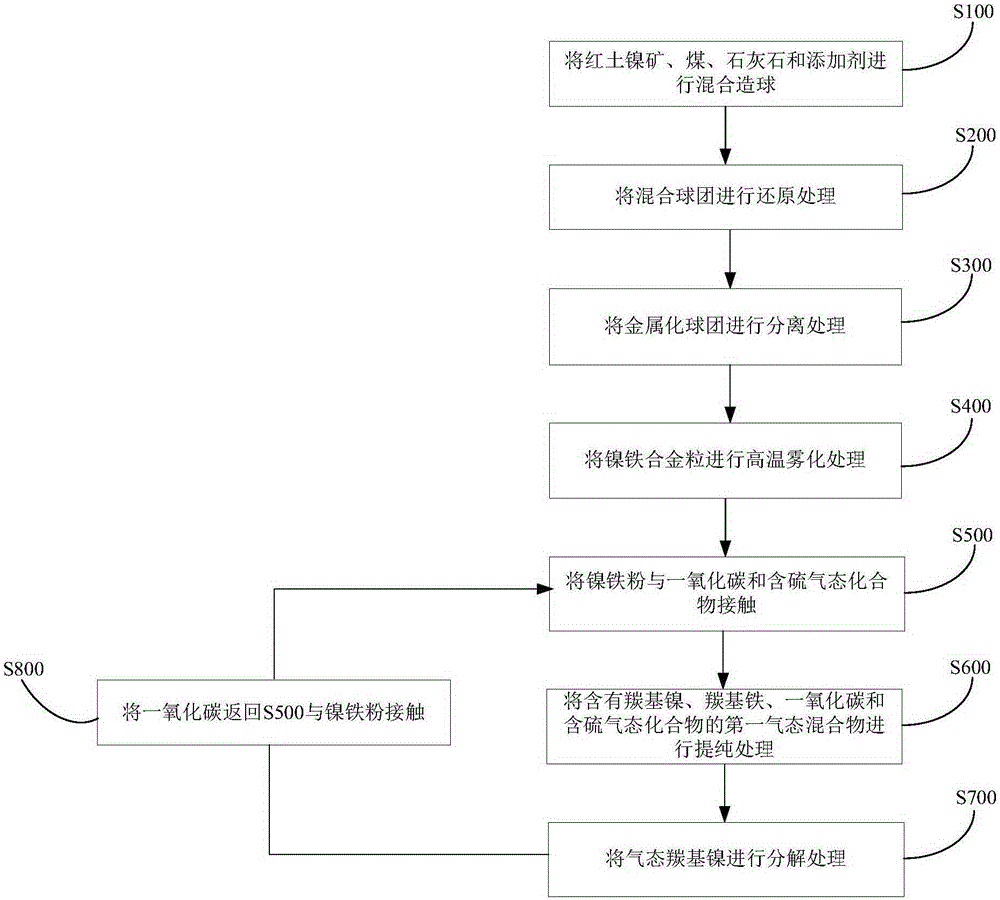

Method and system for preparing nickel carbonyl powder through laterite-nickel ore

A technology of laterite nickel ore and carbonyl nickel powder, which is applied in the field of metallurgy, can solve the problems of high production cost, long natural process flow, and affecting the purity of nickel powder, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

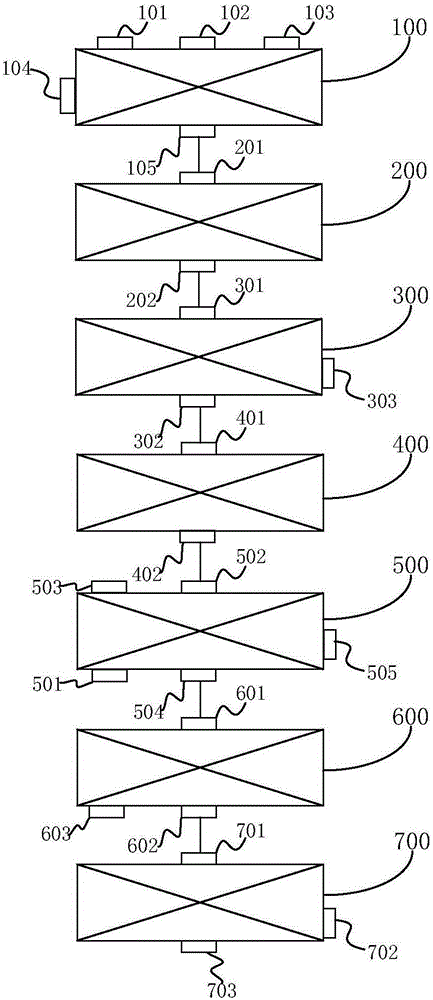

Method used

Image

Examples

Embodiment 1

[0094] Get the laterite nickel ore with a nickel content of 1.45wt%, mix it with coal, limestone and industrial alkali, and then make balls and dry it. Wherein, the mixing ratio of laterite nickel ore, coal, limestone, and industrial alkali is 100:22:20: 3. The dried mixed pellets are placed in a rotary hearth furnace for reduction, the reduction condition is 1300°C, and the time is 35 minutes. The reduced metallized pellets are separated by crushing and magnetic separation to obtain nickel-iron alloy particles and tailings, and then the obtained nickel Ferroalloy particles are subjected to high-temperature atomization treatment to obtain nickel-iron powder (nickel content 8wt%, average particle size 45 μm), and then in the carbonyl reactor, the nickel-iron alloy particles are contacted with carbon monoxide and hydrogen sulfide in countercurrent to generate carbonyl-containing nickel , carbonyl iron, carbon monoxide, hydrogen sulfide first gaseous mixture, carbonylation conditi...

Embodiment 2

[0096] Get nickel content and be the laterite nickel ore of 1.7wt%, blend into coal, limestone and sodium sulfate and mix and then pelletize and dry, wherein, the mixing ratio of laterite nickel ore, coal, limestone and sodium sulfate is 100:15:13: 2. The dried mixed pellets are placed in a rotary hearth furnace for reduction, the reduction condition is 1350°C, and the time is 45 minutes. The reduced metallized pellets are separated by crushing and magnetic separation to obtain nickel-iron alloy particles and tailings, and then the obtained nickel Ferroalloy particles are subjected to high-temperature atomization treatment to obtain nickel-iron powder (nickel content 11wt%, average particle size 30 μm), and then in the carbonyl reactor, the nickel-iron alloy particles are contacted with carbon monoxide and sulfur dioxide in countercurrent to generate carbonylation reaction to generate carbonyl nickel, The first gaseous mixture of carbonyl iron, carbon monoxide and sulfur dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com