Preparation method of sulfuryl fluoride compound

A technology of sulfonyl fluorides and compounds, which is applied in the field of chemical synthesis, can solve the problems such as the difficulty in preparing the raw material sodium sulfinate, and achieve the effects of easy large-scale production, good compatibility, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] More specifically, the invention discloses a method for preparing sulfonyl fluoride compounds, comprising the following steps:

[0056] a), dispersing the sulfonyl hydrazide compound with the structure (I) and the fluorine reagent in a solvent;

[0057]

[0058] b), to the mixture obtained in step a) at 0-100 o Reaction at temperature of C for 2-18h to obtain sulfonyl fluoride compounds containing even structure (II);

[0059]

[0060] Among them, R 1 is aryl, substituted aryl, alkyl or substituted alkyl;

[0061] Preferably, the R 1 When it is an aryl group, it can be divided into phenyl, naphthyl or thienyl;

[0062] Preferably, the R 1 For substituted aryl, p-chlorophenyl, p-methylphenyl, p-nitrophenyl, p-methoxyphenyl, p-trifluoromethylphenyl, p-tert-butylphenyl, p-fluorophenyl , p-acetamidophenyl, 4-chloro-3-nitrophenyl, p-iodophenyl, p-trifluoromethoxyphenyl, p-n-propylphenyl, nitrophenyl, mesityl, 4-methyl-3-fluorophenyl or 3-bromo-5-trifluoromethylp...

Embodiment 1

[0071] In a clean and dry 10 ml Schlenk reaction tube, add 46.5 mg of p-toluenesulfonyl hydrazide, 1-chloromethyl-4-fluoro-1,4-diazobicyclo2.2.2-octanebis( Tetrafluoroborate) 177 mg, and use 2 milliliters of water as reaction solvent, 25 o C stirred the reaction for 2 hours. After the reaction, it was extracted by adding ethyl acetate, and the upper organic phase was directly spin-dried and dissolved with a small amount of petroleum ether and ethyl acetate (volume ratio: 30:1), and separated by a short silica gel column to obtain 34.8 mg of white solid , 80% yield.

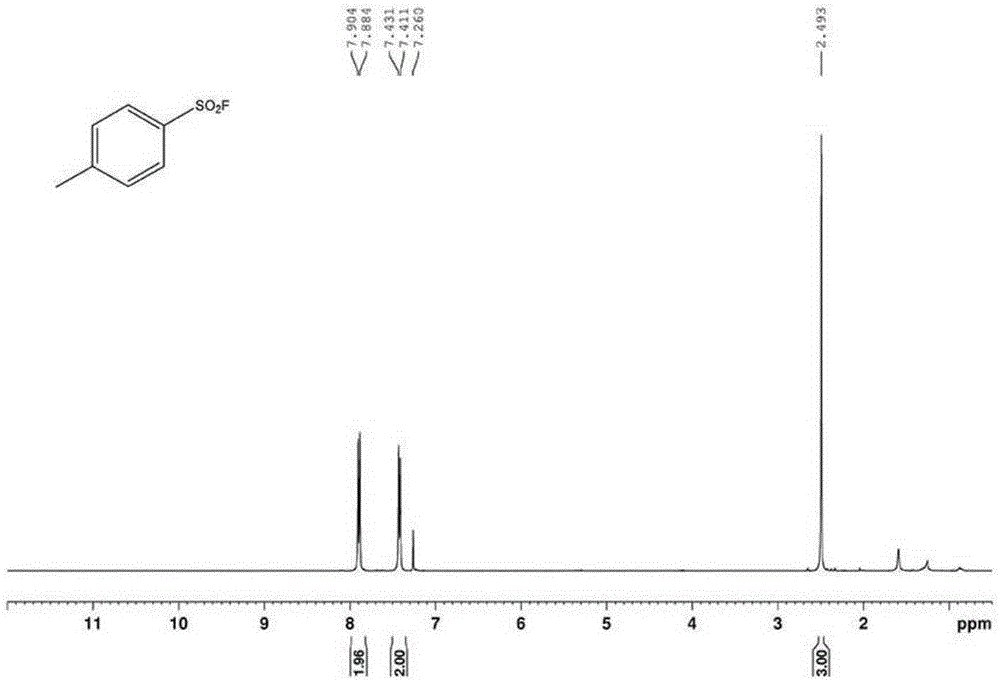

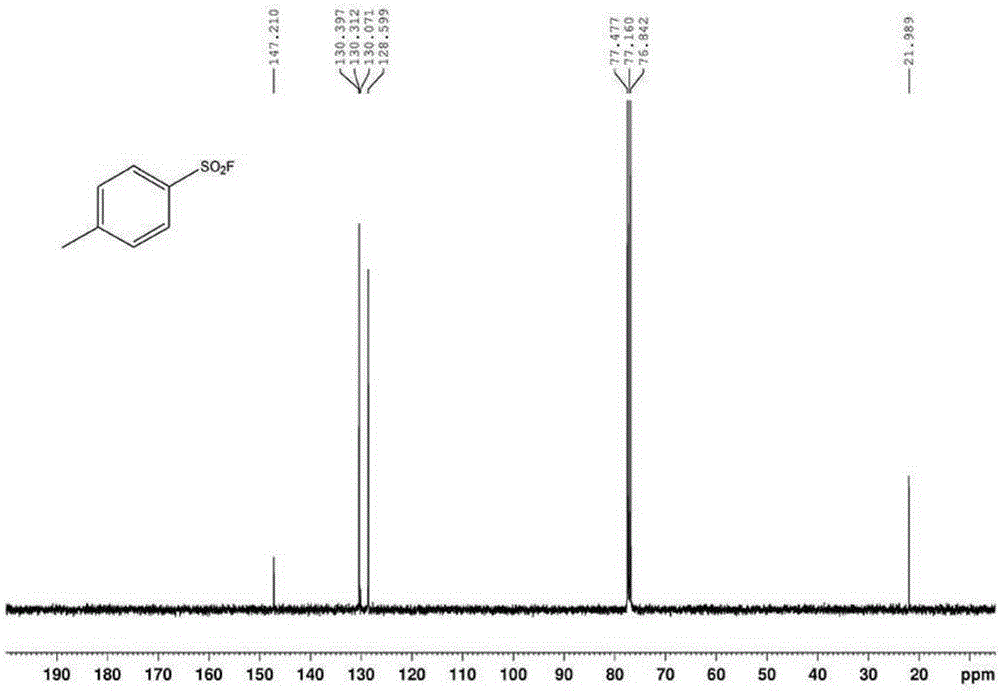

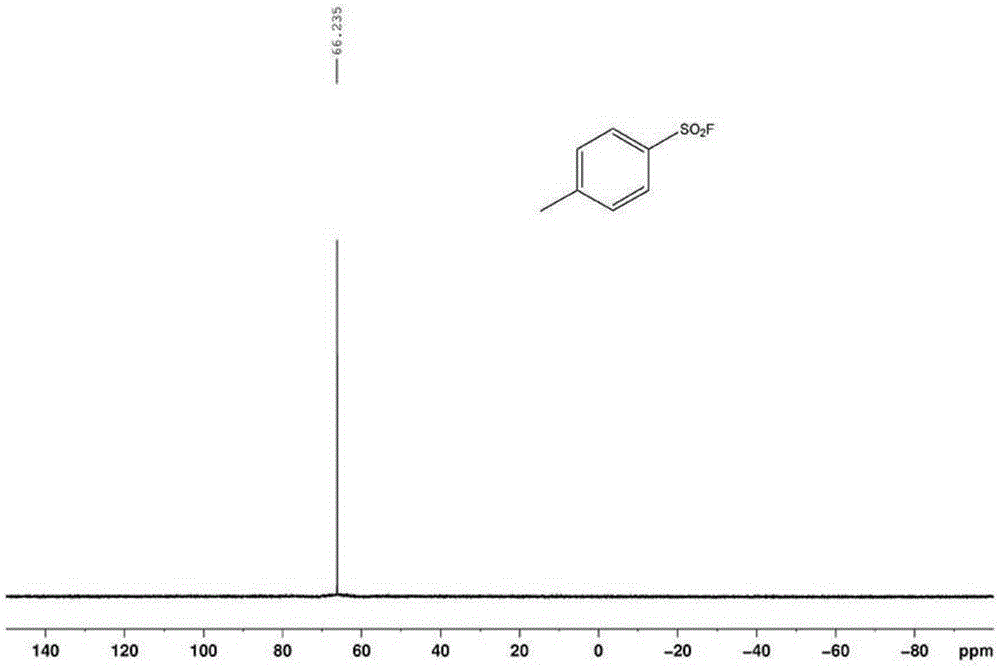

[0072] The proton nuclear magnetic resonance spectrum of the product prepared in this embodiment is as follows: Figure 1a As shown, the carbon NMR spectrum is as Figure 1b As shown, the NMR fluorine spectrum is shown as Figure 1c Shown; It can be confirmed from the spectrum that the product obtained is p-toluenesulfonyl fluoride.

Embodiment 2

[0074] In a clean and dry 10 ml Schlenk reaction tube, add 46.5 mg of p-toluenesulfonyl hydrazide, 1-chloromethyl-4-fluoro-1,4-diazobicyclo2.2.2-octanebis( Tetrafluoroborate) 97 mg, and use 2 milliliters of water as reaction solvent, 25 o C stirred the reaction for 8 hours. After the reaction, it was extracted by adding ethyl acetate, the upper organic phase was directly spin-dried and dissolved with a small amount of petroleum ether and ethyl acetate (volume ratio: 30:1), separated by a short silica gel column to obtain 30.5 mg of white solid , yield 70%.

[0075] The proton nuclear magnetic resonance spectrum of the product prepared in this embodiment is as follows: Figure 1a As shown, the carbon NMR spectrum is as Figure 1b As shown, the NMR fluorine spectrum is shown as Figure 1c shown. It can be confirmed from the spectrum that the obtained product is p-toluenesulfonyl fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com