Nosiheptide finemeal extracting method

An extraction method, nosiheptide technology, applied in the field of veterinary drug preparation, can solve problems such as unsuitability for industrial production, difficulty in extraction work, and reduced product yield, and achieve the effects of reducing waste water pollution, reducing production costs, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

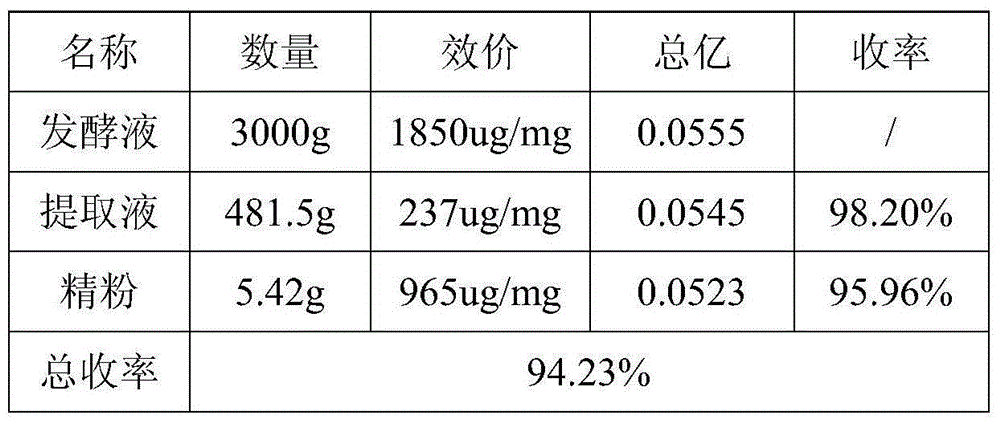

Embodiment 1

[0022] (1) Get inactivated nosiheptide fermentation broth 3000g, add diatomaceous earth 30g, adopt horizontal spiral sedimentation centrifuge centrifugal treatment, obtain the filter residue (containing water) of 120g containing nosiheptide;

[0023] (2) Take the nosiheptide filter residue obtained in step (1), add 360g dichloroethane solvent therein, and stir at 45°C for 0.5 hour, filter, separate layers, take the organic phase, and obtain 364g nosiheptide extract and 116g Mycelium filter residue;

[0024] (3) Take the local mycelium filter residue obtained in step (2), add 116g of dichloroethane therein, and stir at 45°C for 0.5 hours, filter, separate layers, take the organic phase, and obtain 117.5g of nosiheptide extract;

[0025] (4) Combine step (2) and (3) obtained cetide extracts, distill under reduced pressure to dryness, add deionized water 481.5g deionized water to it at room temperature, filter, filter cake is washed with water, dried, ground to obtain 5.42g nosi...

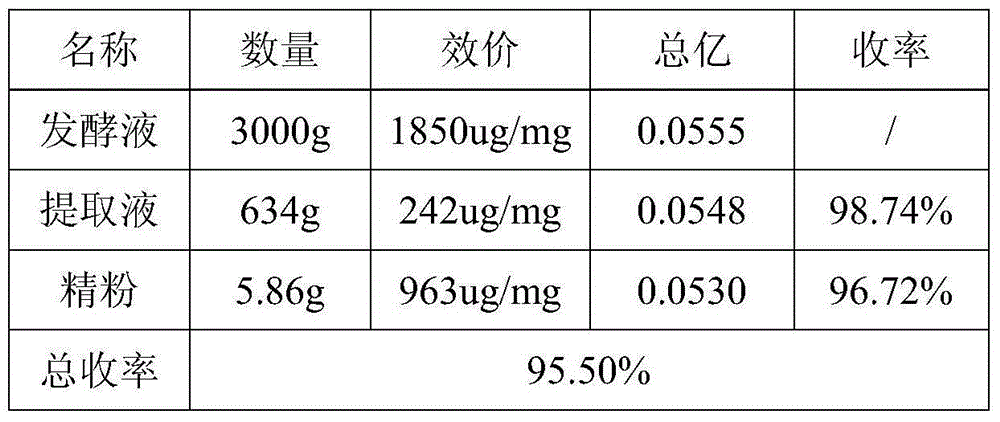

Embodiment 2

[0030] (1) Get inactivated nosiheptide fermentation broth 3000g, add diatomaceous earth 30g, adopt horizontal spiral sedimentation centrifuge centrifugal treatment, obtain the filter residue (containing water) of 120g containing nosiheptide;

[0031] (2) Take the nosiheptide filter residue obtained in step (1), add 480g dichloroethane solvent therein, and stir at 48°C for 0.8 hours, filter, separate layers, take the organic phase, and obtain 512g nosiheptide extract and 88g Mycelium filter residue;

[0032] (3) Take the local mycelium filter residue obtained in step (2), add 132g dichloroethane therein, and stir at 48°C for 0.8 hours, filter, separate layers, take the organic phase, and obtain 122g nosiheptide extract;

[0033] (4) Combine step (2), (3) obtained cetide extracts, distill under reduced pressure to dryness, add deionized water 698g deionized water to it at room temperature, filter, filter cake is washed with water, dried, ground to obtain 5.86 g nosiheptide powd...

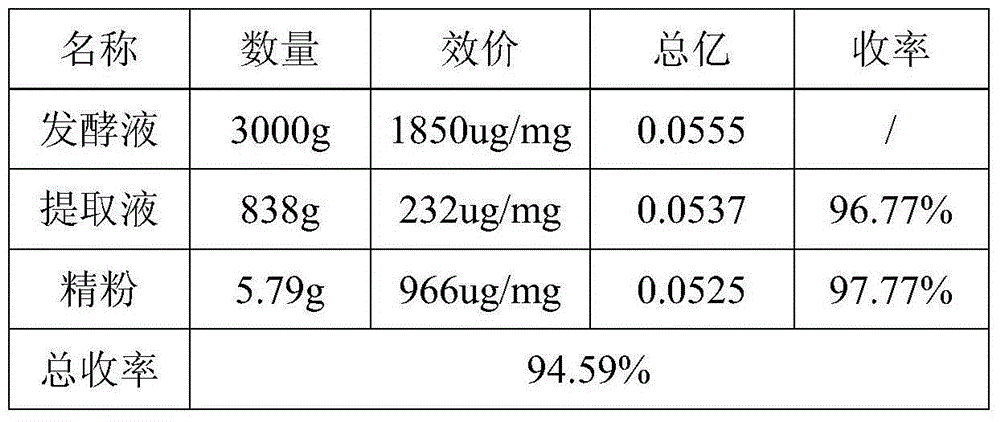

Embodiment 3

[0038] (1) Get inactivated nosiheptide fermentation broth 3000g, add diatomaceous earth 30g, adopt horizontal spiral sedimentation centrifuge centrifugal treatment, obtain the filter residue (containing water) of 120g containing nosiheptide;

[0039] (2) Take the nosiheptide filter residue obtained in step (1), add 600g dichloroethane solvent therein, and stir for 1 hour at 50°C, filter, separate layers, take the organic phase, and obtain 615g nosiheptide extract and 105g Mycelium filter residue;

[0040] (3) Take the mycelium filter residue obtained in step (2), add 210g of dichloroethane therein, and stir at 50°C for 1 hour, filter, separate layers, take the organic phase, and obtain 223g of nosiheptide extract;

[0041] (4) Combine the cetide extracts obtained in steps (2) and (3), distill to dryness under reduced pressure, add 1257g of deionized water to it at room temperature, filter, and wash the filter cake with water, dry and grind to obtain 5.79g of cetide Peptide po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com