A kind of high elongation silicone sealant and preparation method thereof

A silicone sealant, high elongation technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc. problems, to achieve the effect of long service life, strong weather resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

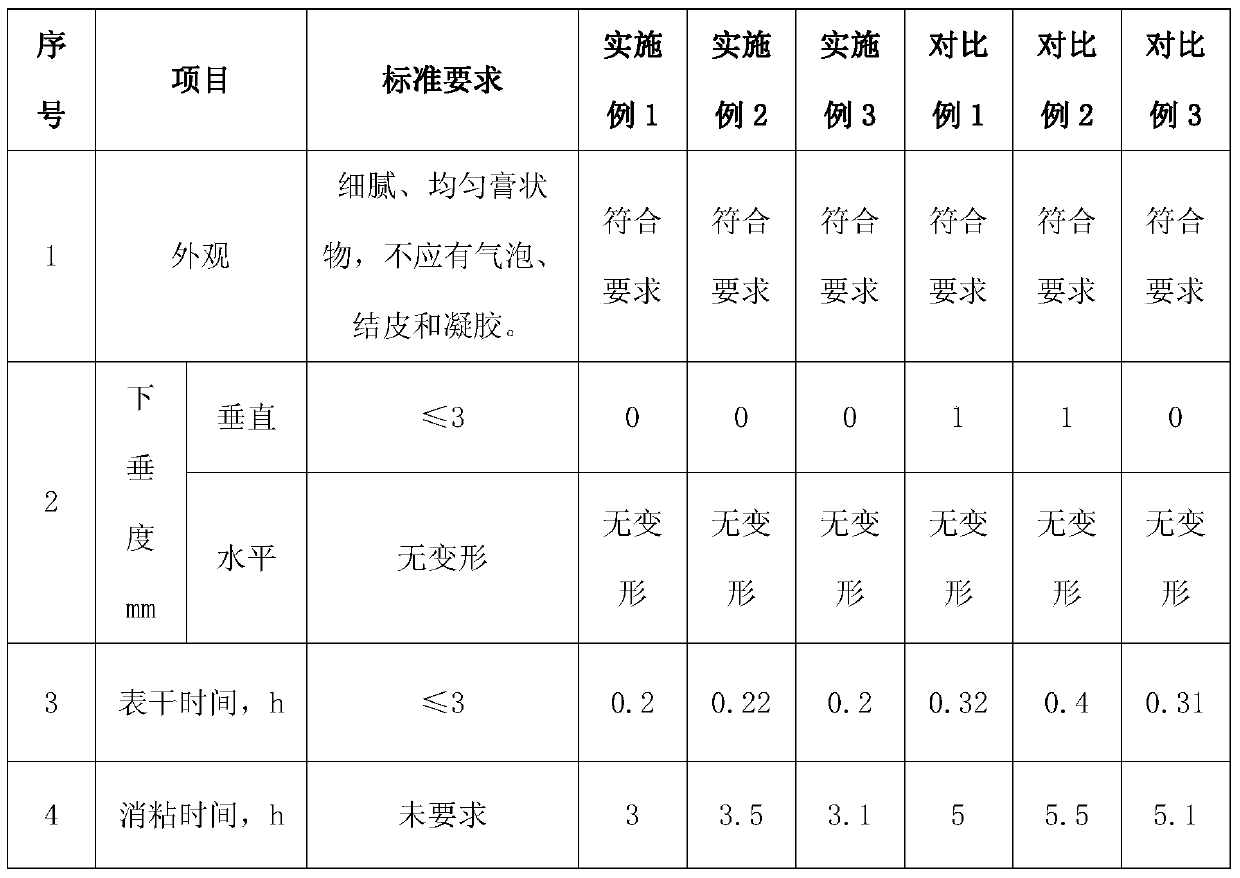

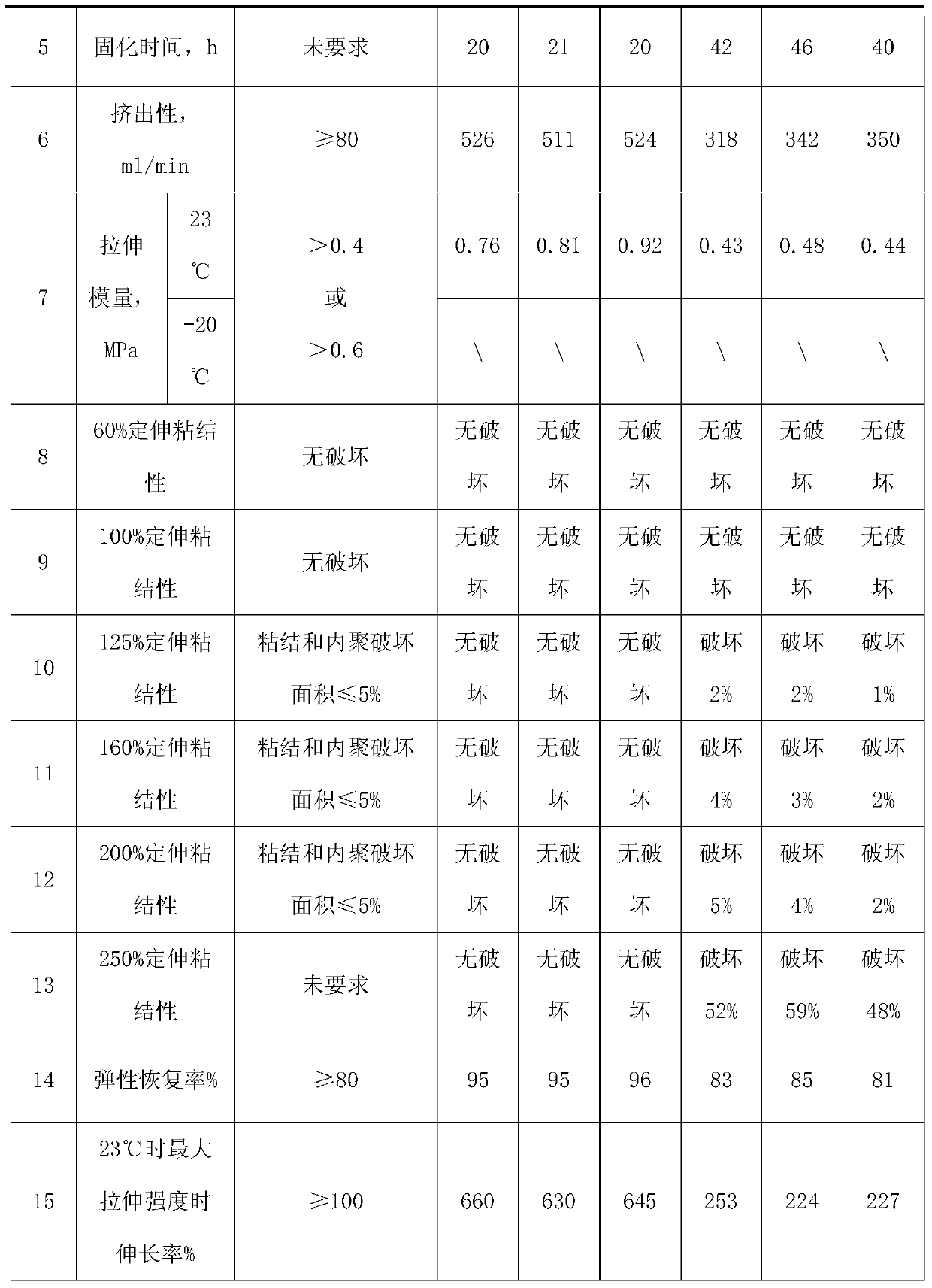

Examples

Embodiment 1

[0031] A high-elongation silicone sealant, in parts by mass, comprising the following raw materials: 25 parts of α, ω-dimethoxy polydimethylsiloxane with a viscosity of 0.5 million centipoise, and a viscosity of 60 centipoise 1.8 parts of DL-400, 22 parts of base material, 6.5 parts of fumed silica, 39 parts of quartz powder, 4.2 parts of methyltrimethoxysilane, 0.8 parts of primary titanium, 0.5 parts of secondary titanium, γ-(2,3 - 0.14 parts of glycidyloxy) propyltrimethoxysilane, 0.06 part of dibutyltin dilaurate, the silicone sealant proposed by the present invention can greatly improve the displacement resistance, and can be used for long-term aluminum curtain wall joints, highways, Bridges, airports and other concrete pavement gaps, caulking and sealing of expansion joints and other construction occasions, and the effective use period of the sealant is longer.

[0032] In parts by mass, the base material is composed of 50 parts of methyl silicone oil with a viscosity of...

Embodiment 2

[0043] A high-elongation silicone sealant, in parts by mass, comprising the following raw materials: 65.4 parts of α, ω-dimethoxy polydimethylsiloxane with a viscosity of 250,000 centipoise and a viscosity of 600 centipoise 0.2 parts of DL-30000, 8 parts of base material, 2.5 parts of fumed silica, 18 parts of quartz powder, 2.5 parts of vinyltrimethoxysilane, 1.6 parts of primary titanium, 1.2 parts of secondary titanium, γ-(2,3 -Glycidoxy) propylmethyl dimethoxysilane, γ-aminopropyltriethoxysilane, 0.58 parts of mixed coupling agent of γ-aminopropylmethyldimethoxysilane, dibutyl Tin diacetate 0.02 parts, the silicone sealant proposed by the present invention can greatly improve the displacement resistance, and can be used for long-term use in aluminum curtain wall joints, gaps in concrete roads such as expressways, bridges, airports, caulking and sealing of expansion joints, etc. Construction occasions, and the effective use period of the sealant is longer.

[0044] In part...

Embodiment 3

[0055] A high-elongation silicone sealant, in parts by mass, comprising the following raw materials: 39.2 parts of α, ω-dimethoxy polydimethylsiloxane with a viscosity of 50,000 centipoise and a viscosity of 70 centipoise 0.55 parts of DL-4000, 19.6 parts of base material, 2.9 parts of fumed silica, 32.4 parts of quartz powder, 2.9 parts of vinyl triethoxysilane and methyl triethoxysilane mixed crosslinking agent, 1.2 parts of primary titanium , 0.9 parts of secondary titanium, 0.3 parts of γ-mercaptopropyl trimethoxysilane, 0.3 parts of mixed coupling agent of γ-mercaptopropyl triethoxysilane, 0.05 parts of stannous octoate, the silicone sealant proposed by the present invention, greatly It can improve the anti-displacement ability, and can be used for long-term construction occasions such as joints of aluminum curtain walls, joints of concrete roads such as highways, bridges, and airports, and caulking of expansion joints, and the effective use period of the sealant is longer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com