UV curing grid exhaust glue and preparation method thereof

A grid and adhesive layer technology, applied in the field of UV curing grid venting adhesive and its preparation, can solve the problems of poor fit, generation of air bubbles, and poor anti-drop performance of stretch-reducing adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

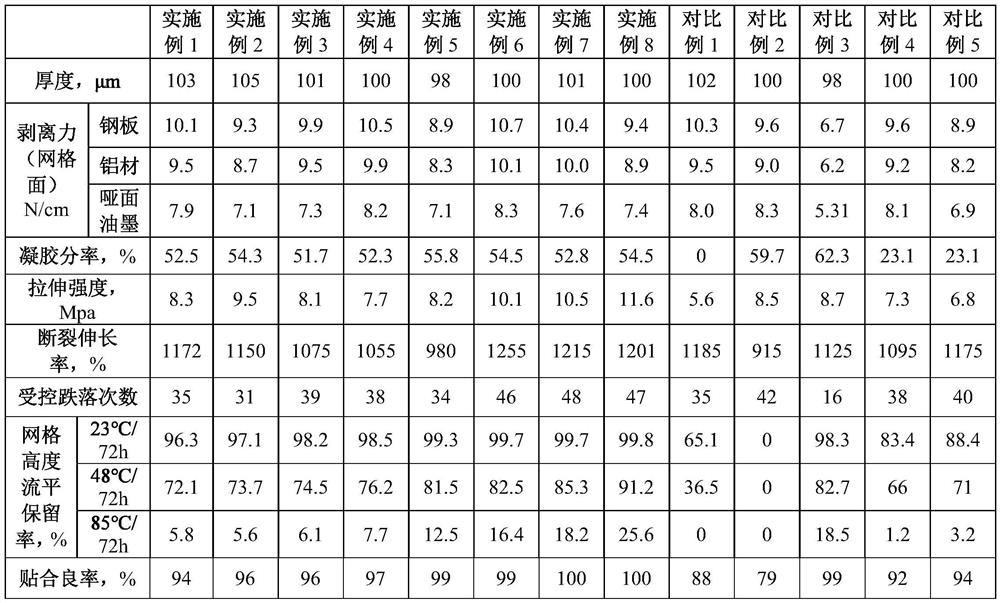

Examples

Embodiment 1

[0049] A preparation method of UV curing grid exhaust glue, comprising the steps of:

[0050] (1) The raw materials of the adhesive layer: styrene block copolymer modified by vinyl grafting, tackifying resin, aging agent, free radical photoinitiator, and expansion ball are dissolved in toluene / heptane with a solid content of 45%. Stir and dissolve in the alkane system, and then let stand to defoam to obtain stretched viscose-reducing glue;

[0051] In terms of parts by mass, the component content of the adhesive layer raw material is: vinyl graft modified styrene-butadiene-styrene block copolymer (U.S. Kraton DX0222, 20% styrene block, 18% diblock content) 50 parts, tackifying resin (39.6 parts Crayville Wingtack Extra, ring and ball softening point temperature 100°C; 5 parts Crayville Wingtack W140, ring and ball softening point temperature 140°C; 2.8 parts of liquid rosin resin (GA-AT) from Arakawa, Japan) 47.4 parts, aging agent (tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphe...

Embodiment 2

[0054] A preparation method of UV curing grid exhaust glue, comprising the steps of:

[0055] (1) The raw materials of the adhesive layer: styrene block copolymer modified by vinyl grafting, tackifying resin, aging agent, free radical photoinitiator, and expansion ball are dissolved in toluene / heptane with a solid content of 45%. Stir and dissolve in the alkane system, and then let stand to defoam to obtain stretched viscose-reducing glue;

[0056] In terms of parts by mass, the component content of the adhesive layer raw material glue is: vinyl graft modified styrene-butadiene-styrene block copolymer (U.S. Kraton DX0222, 20% benzene Ethylene block, 18% diblock content) 54.4 parts, tackifying resin (36.9 parts Crayville Wingtack Extra, ring and ball softening point temperature 100°C; 3.5 parts Crayville Wingtack W140, ring and ball softening point temperature 140°C ; 2.6 parts of liquid rosin resin (GA-AT) of Arakawa, Japan) 43 parts, aging agent (β-(3,5-di-tert-butyl-4-hydro...

Embodiment 3

[0059] A preparation method of UV curing grid exhaust glue, comprising the steps of:

[0060] (1) The raw materials of the adhesive layer: styrene block copolymer modified by vinyl grafting, tackifying resin, aging agent, free radical photoinitiator, and expansion ball are dissolved in toluene / heptane with a solid content of 45%. Stir and dissolve in the alkane system, and then let stand to defoam to obtain stretched viscose-reducing glue;

[0061]In terms of parts by mass, the component content of the adhesive layer raw material is: vinyl graft modified styrene-butadiene-styrene block copolymer (U.S. Kraton DX0222, 20% styrene Block, 18% diblock content) 51 parts, tackifying resin (39 parts of Crayville Wingtack Extra, ring and ball softening point temperature 100°C; 4.6 parts of Crayville Wingtack W140, ring and ball softening point temperature 140°C; 2.8 parts of liquid rosin resin GA-AT of Arakawa, Japan) 46.4 parts, aging agent (butylmalonate mixture) 1.08 parts, photoin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com