Bolt surface corrosion prevention method

An anti-corrosion and bolting technology, applied in the field of electrochemical surface treatment, can solve problems such as unsatisfactory adhesion and difficult peeling of the oxide layer, and achieve the effects of good surface strength, outstanding corrosion resistance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 In 45# bolt surface ionic liquid electrodeposition aluminum-manganese alloy coating, concrete steps are as follows:

[0038] (1): Use one-step degreasing method to degrease and degrease 45# bolts. The degreasing agent is sodium hydroxide 20g / L, sodium carbonate 10g / L, trisodium phosphate 15g / L and the rest of deionized water. Put the 45# bolt workpiece as the cathode, and the 304 stainless steel plate as the anode, put it into the electrolyte at a temperature of 60°C, and apply a current density of 10mA / cm 2 , electrolytic degreasing 30s. Subsequently, the 45# bolt workpiece that has been electrolytically degreased is immersed in 20% HCl and cleaned for 5 minutes to preliminarily remove the oxide film on the surface of the substrate.

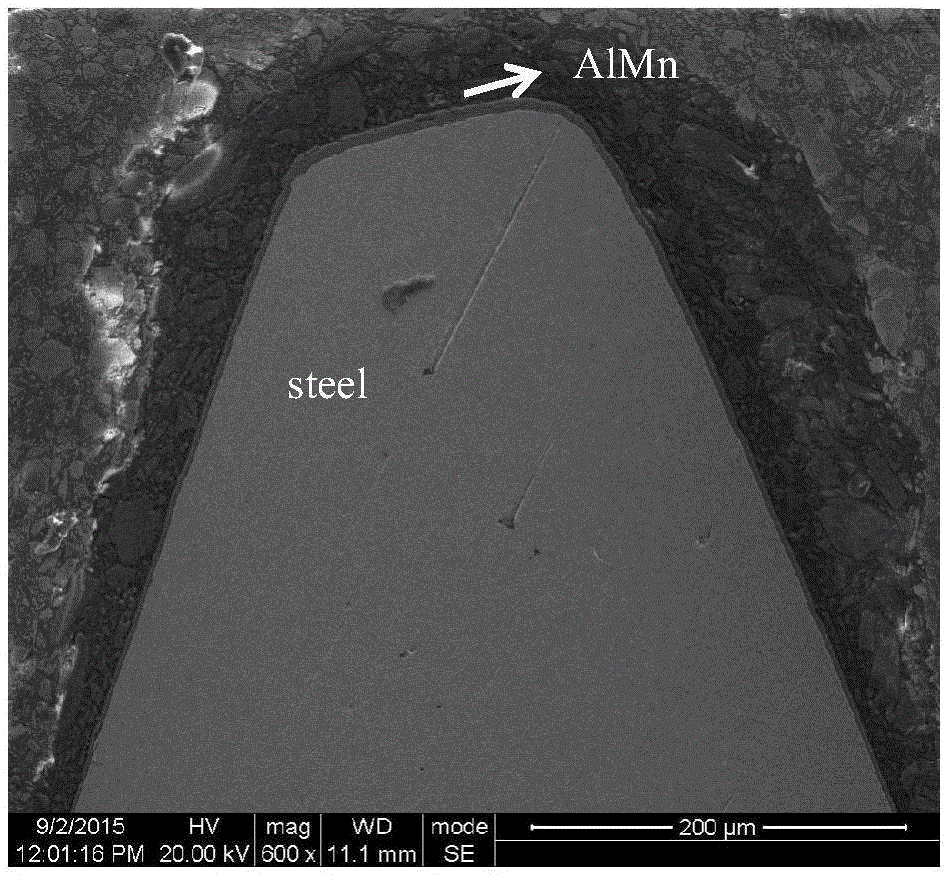

[0039] (2) The above-mentioned 45# bolts processed through the steps are immersed in the activation solution to carry out anodic activation treatment, with the 45# bolt workpiece as the anode, and the Al plate (purity 99.9wt...

Embodiment 2

[0046] Embodiment 2: ionic liquid electrodeposits aluminum-manganese alloy coating on the surface of 304 stainless steel bolts, the specific steps are as follows:

[0047] (1): Use one-step degreasing method to degrease and degrease 304 stainless steel bolts. The degreasing agent is sodium hydroxide 30g / L, sodium carbonate 30g / L, trisodium phosphate 5g / L and the rest of deionized water. Put the 304 stainless steel bolt workpiece as the cathode, and the 304 stainless steel plate as the anode, put it into the electrolyte at a temperature of 60°C, and apply a current density of 5mA / cm 2 , electrolytic degreasing 1min. Subsequently, the 304 stainless steel bolt workpiece that has been electrolytically degreased is immersed in 10% HCl and cleaned for 10 minutes to initially remove the oxide film on the surface of the substrate.

[0048] (2) The above-mentioned 304 stainless steel bolts processed through the steps are immersed in the activation solution to carry out anodic activati...

Embodiment 3-6

[0054] The 304 stainless steel bolt workpiece was treated with the same pretreatment method as in Example 2, and then the surface deposition electroplating was performed using the same electroplating method. There are only some differences in the temperature and composition ratio of the ionic liquid during the electroplating process, the current density and time of electroplating, etc., see Table 1 below for details.

[0055] Table 1

[0056]

[0057] *The composition ratio is the molar ratio of 1-methyl-3-ethylimidazole chloride and AlCl3

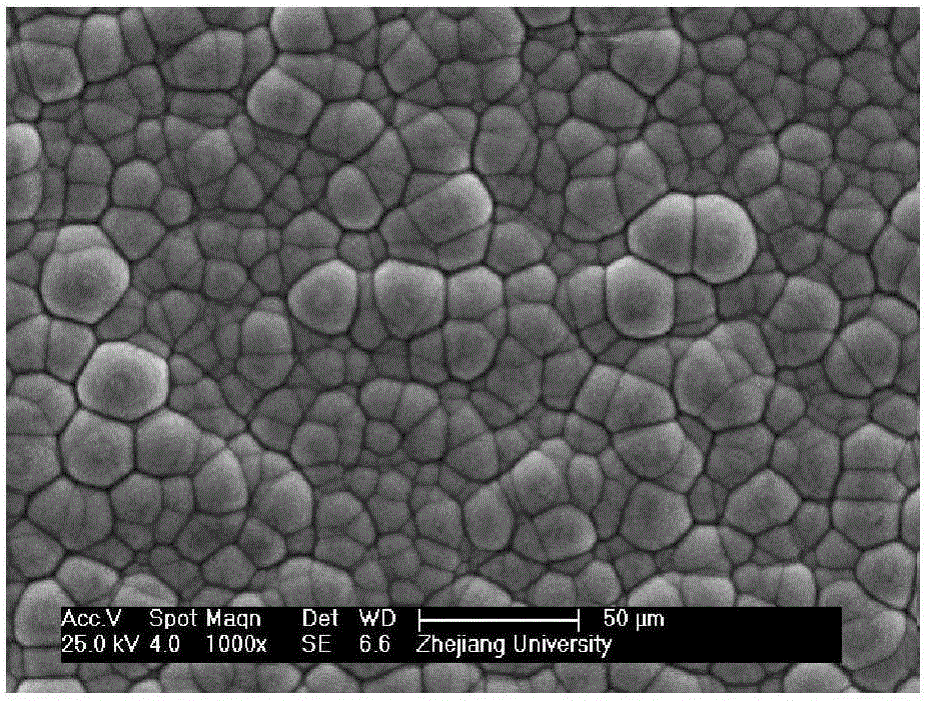

[0058] As can be seen from the above examples, when the control current density 6-10mA / cm 2 , when the ratio of aluminum trichloride and EMIC in the selected ionic liquid is 1 to 2:1, when MnCl 2 The concentration is 0.2-0.3mol / L, and the obtained coating is amorphous. When the MnCl2 concentration is 0.1mol / L, 20mA / cm 2 High-current electroplating can obtain a crystalline phase coating. Control the current density at 6-10mA / cm 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com