Glass fiber reinforced plastic complete equipment for purifying yellow phosphorus tail gas

A technology of yellow phosphorus tail gas and complete equipment, applied in the direction of carbon monoxide, air quality improvement, chemical instruments and methods, etc., can solve the problems of waste of resources, failure to recycle, pollute the environment, etc., to prevent corrosion, increase concentration, and increase exposure area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

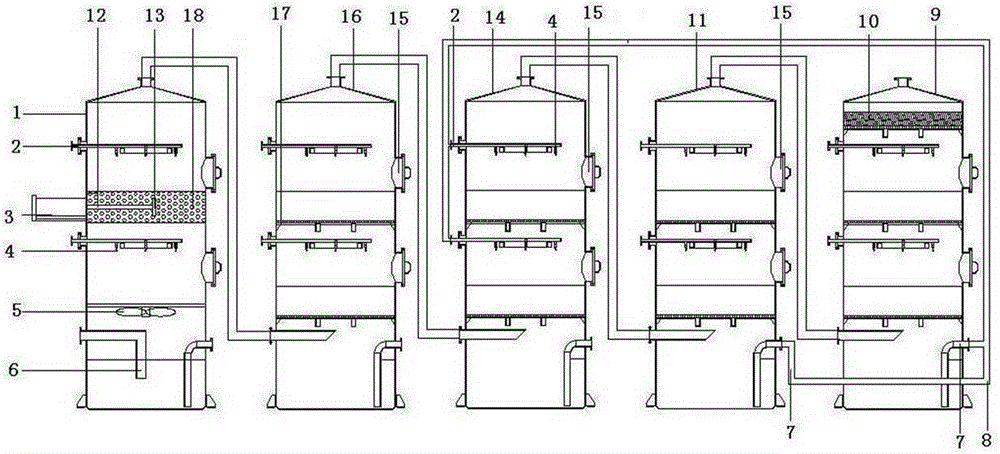

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] like figure 1 A complete set of equipment for purifying FRP for yellow phosphorus tail gas is shown, including a water washing tower 1, an alkali washing tower 16, a first salt washing tower 14, a second salt washing tower 11, a third salt washing tower 9, a liquid inlet pipe 2, and a nozzle 4 , packing plate 17, air inlet 6, it is characterized in that: washing tower 1 right side is provided with alkali washing tower 16, the first salt washing tower 14, the second salt washing tower 11, the 3rd salt washing tower 9 successively, water washing tower 1. Alkali washing tower 16, the first salt washing tower 14, the second salt washing tower 11, and the third salt washing tower 9 are respectively provided with liquid inlet pipes 2 in the middle and upper parts, and a number of nozzles 4 are arranged at the lower part of the liquid inlet pipe 2. Tower 1, alkali washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com