Surface imprinting chitosan microspheres for efficiently selecting heavy-metal ions and preparation method for surface imprinting chitosan microspheres

A technology of chitosan microspheres and heavy metal ions, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of complex synthesis operations and harsh conditions, and achieve simple synthesis operations , Mild cross-linking conditions and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

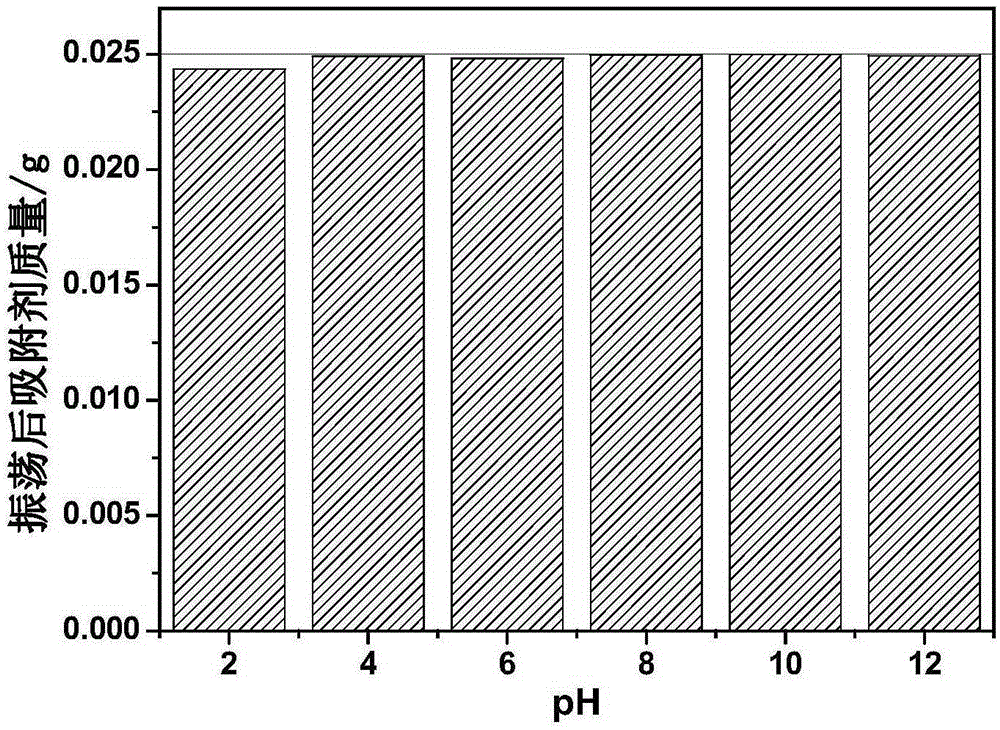

[0034] A kind of surface imprinted chitosan microsphere of ultrahigh selective separation Cu (II), its step is:

[0035] (1) Preparation of chitosan microspheres: accurately weigh 4g chitosan powder and dissolve in 100mL volume concentration of 2% acetic acid solution, then drip the chitosan solution into a 250mL coagulation bath with a peristaltic pump and solidify into a ball , the coagulation bath is prepared by 200mL distilled water, 16g sodium hydroxide and 50mL ethanol, after standing for 30min, chitosan microspheres (referred to as CS) are filtered out, washed and placed in distilled water for preservation;

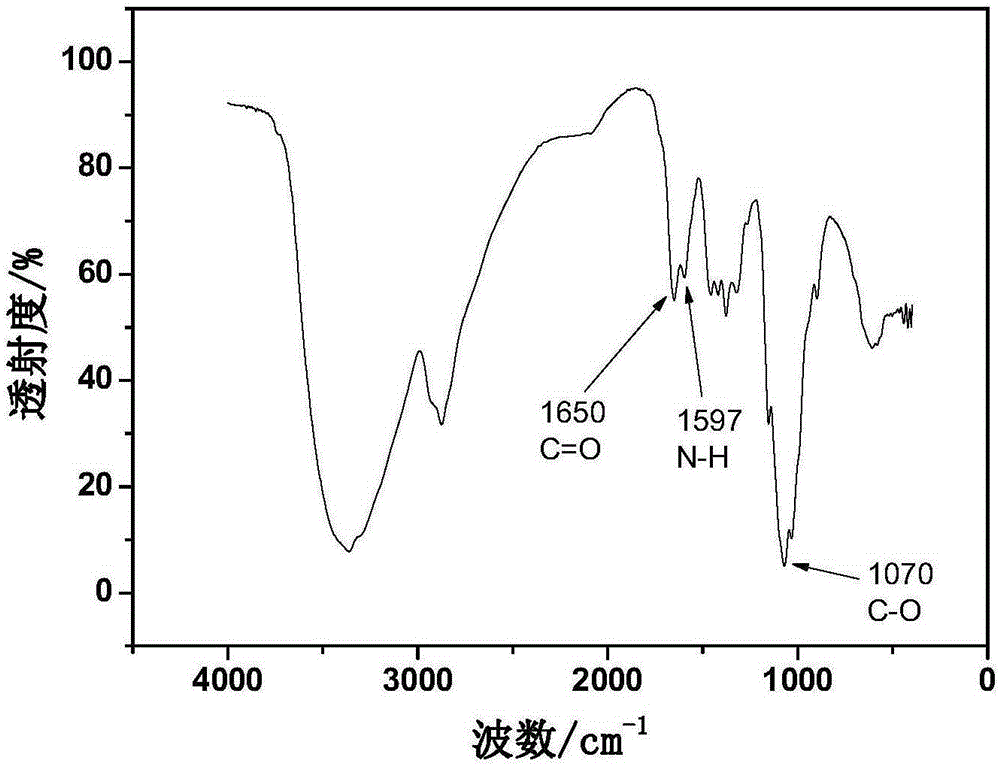

[0036] (2) Preparation of carboxylated chitosan microspheres: Weigh the chitosan microspheres gained in step (1) and place 100 mL of mass concentration in 8% sodium chloroacetate aqueous solution, adjust pH=13 with NaOH, at 80° C. Heated and stirred in an oil bath for 10 hours to obtain chloromethylated chitosan microspheres (referred to as CS-COONa), took out the ...

Embodiment 2

[0047] With embodiment 1, difference is:

[0048] The volume fraction of acetic acid is 8% in the step (1), and the mass fraction of chitosan solution is 2%, and coagulation bath is prepared by 200mL distilled water, 8g sodium hydroxide and 10mL ethanol;

[0049] The mass concentration of sodium chloroacetate in step (2) is 2%, adjust pH=8 with alkaline solution, heat to 60°C and stir for 5h;

[0050] In step (3), the molecular weight of polyethyleneimine is 7500, and the molar ratio of polyethyleneimine to heavy metal ions is 4:1. After adding copper nitrate solution (concentration is 20mmol / L) and shaking for 10h, add chloromethylation Chitosan microspheres (dosing amount is 50g / L) are shaken and adsorbed at 60°C for 60h; Cross-linking reaction at 80℃ for 10h;

[0051] The mass concentration of the EDTA solution in the step (4) is 20%, and the alkali solution is a 1 mmol / L NaOH solution.

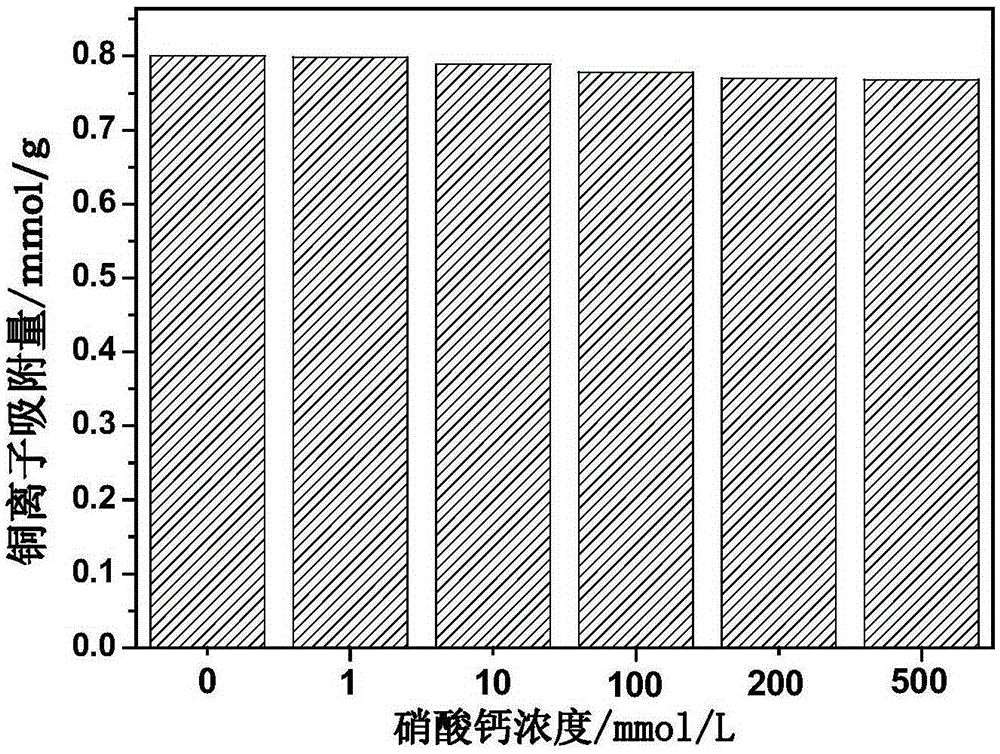

[0052] Gained microspheres have an adsorption capacity of 0.61mmol / g under the same...

Embodiment 3

[0054] With embodiment 1, difference is:

[0055] The volume fraction of acetic acid is 6% in the step (1), and the mass fraction of chitosan solution is 3%, and coagulation bath is prepared by 200mL distilled water, 32g sodium hydroxide and 80mL ethanol;

[0056] The mass concentration of sodium chloroacetate in step (2) is 20%, adjust pH=14 with alkaline solution, heat to 20°C and stir for 8h;

[0057] In step (3), the molecular weight of polyethyleneimine is 9000, and the molar ratio of polyethyleneimine to heavy metal ion is 3:1. After adding copper nitrate solution (concentration is 1mmol / L) and shaking for 8h, add chloromethylation Chitosan microspheres (dosing amount is 20g / L) are shaken and adsorbed at 40°C for 10h; Cross-linking reaction at 20°C for 3 hours;

[0058] The mass concentration of the EDTA solution in the step (4) is 4%, and the alkali solution is a 0.5 mmol / L NaOH solution.

[0059] Gained microspheres have an adsorption capacity of 0.84mmol / g under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com