Method and device for preparing high-purity tungsten hexachloride

A technology of pure tungsten hexachloride and tungsten hexachloride, which is applied in the field of preparation of high-purity tungsten hexachloride, can solve problems affecting the purity of tungsten hexachloride, low output of tungsten hexachloride, and affecting quality, and achieve effective It is conducive to the maximum utilization of resources, significant economic and social benefits, and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

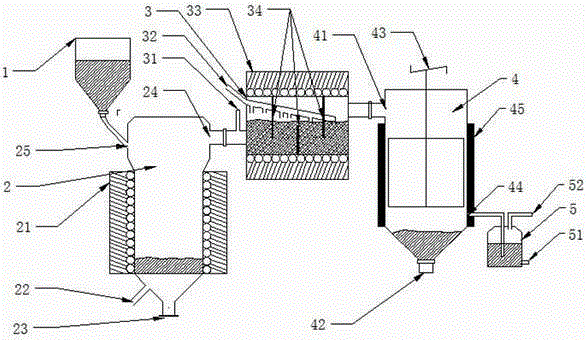

[0026] Such as figure 1 , a preparation device for high-purity tungsten hexachloride, comprising a chlorination furnace 2, a receiver 4 and an absorption tank 5, a tungsten powder inlet 25 at a position of 1 / 6 to 1 / 4 of the upper end of the chlorination furnace 2, and The tungsten powder chamber 1 is connected, there is a crude tungsten hexachloride vapor outlet 26 at the other side of the upper end at 1 / 8~1 / 6, the purified chlorine gas inlet 22 at the lower end at 1 / 8~1 / 6, and dust at the bottom Outlet 23, there is a resistance furnace 21 on the outside for heating and temperature control, the top of the receiver 4 is connected to a scraper 43, there is a cooling water layer 45 outside the receiver 4, and 1 / 8~1 / 4 of the upper end of the receiver 4 is connected to tungsten hexachloride The steam inlet 11, the waste gas outlet 44 is set at 1 / 3~1 / 2 of the lower end of the receiver 4, which is connected to the absorption tank 5, and the bottom end of the receiver 4 is connected t...

Embodiment 2

[0029] Tungsten powder and activated carbon powder with a particle size >75um are obtained by sintering and sieving. Chlorine gas is purified and preheated at the same time. The amount of tungsten added and the output of tungsten hexachloride are used as standards to adjust the flow rate of chlorine gas and the amount of activated carbon added to make tungsten powder and chlorine gas The ratio is 100:400, the amount of chlorine gas entering the chlorination furnace is 90% of the total intake of chlorine gas, tungsten powder reacts with chlorine gas at a temperature of 800°C, steam enters the refining furnace to react with activated carbon and chlorine gas at a temperature of 750°C, and the reaction consumes activated carbon The molar ratio of tungsten powder and chlorine gas is 5:100:400, the refined steam enters the receiver, the temperature of the cooling water is controlled at 30-250°C, and tungsten hexachloride is obtained at the bottom, which is absorbed by the sodium hydro...

Embodiment 3

[0031] Tungsten powder and activated carbon powder with a particle size >75um are obtained by sintering and sieving. Chlorine gas is purified and preheated at the same time. The amount of tungsten added and the output of tungsten hexachloride are used as standards to adjust the flow rate of chlorine gas and the amount of activated carbon added to make tungsten powder and chlorine gas The ratio is 100:500, the amount of chlorine gas entering the chlorination furnace is 90% of the total intake of chlorine gas, tungsten powder reacts with chlorine gas at a temperature of 900°C, steam enters the refining furnace to react with activated carbon and chlorine gas at a temperature of 850°C, and the reaction consumes The molar ratio of activated carbon to tungsten powder and chlorine gas is 8:100:500. Refined steam enters the receiver, the temperature of cooling water is controlled at 30-250°C, and tungsten hexachloride is obtained at the bottom, which is absorbed by sodium hydroxide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com