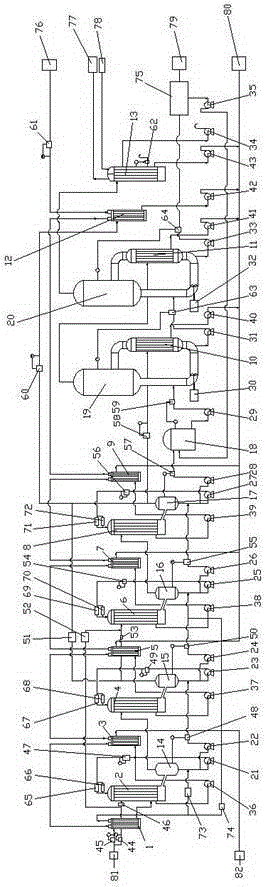

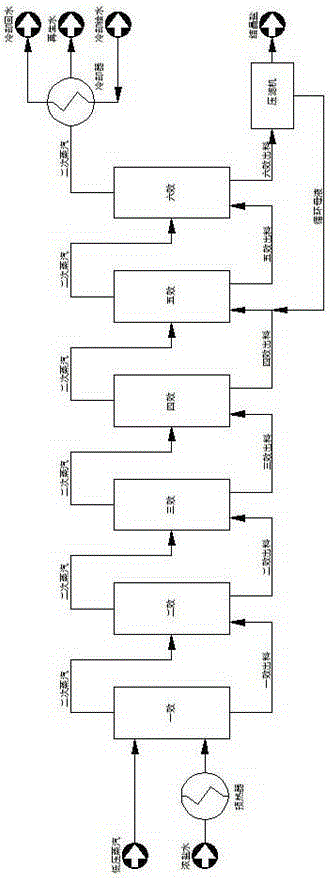

Six-effect evaporative crystallization device and process applied to zero discharge of industrial wastewater

A technology of industrial waste water and crystallization device, which is applied in the direction of general water supply saving, heating water/sewage treatment, etc., and can solve problems such as large volume, small number of effects, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Through this equipment and process, a kind of industrial wastewater containing inorganic salts (mainly composed of NaCl, Na2SO4, NaCO3, etc.) is treated, and this wastewater is concentrated brine; The regulating pool is pumped to the device of the present invention for processing through the regulating pool afterwards; the heat used comes from outside the world through the 0.5MPaG low-pressure saturated steam buffered and stabilized by the steam drum; after evaporation, there are two kinds of condensate, which are respectively saturated steam condensate and The temperature of the secondary steam condensate is about 80-90°C and 30-40°C. The saturated steam condensate is sent to the desalination station outside the boundary, and the secondary steam condensate is sent to the reuse water station outside the boundary; the device is equipped with an emergency pool. It is a comprehensive recovery of chemical washing wastewater, accident drainage and other wastewater, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com