A large-scale solvent-free electrospinning method for preparing photocurable material micro-nano fibers

A technology of light-curing materials and micro-nano fibers, which can be used in spinning solution preparation, fiber treatment, textiles and papermaking, etc. It can solve problems such as inability to produce on a large scale, complex configuration process, and incomplete curing, so as to avoid oxygen-inhibited polymerization Phenomenon, good continuity, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

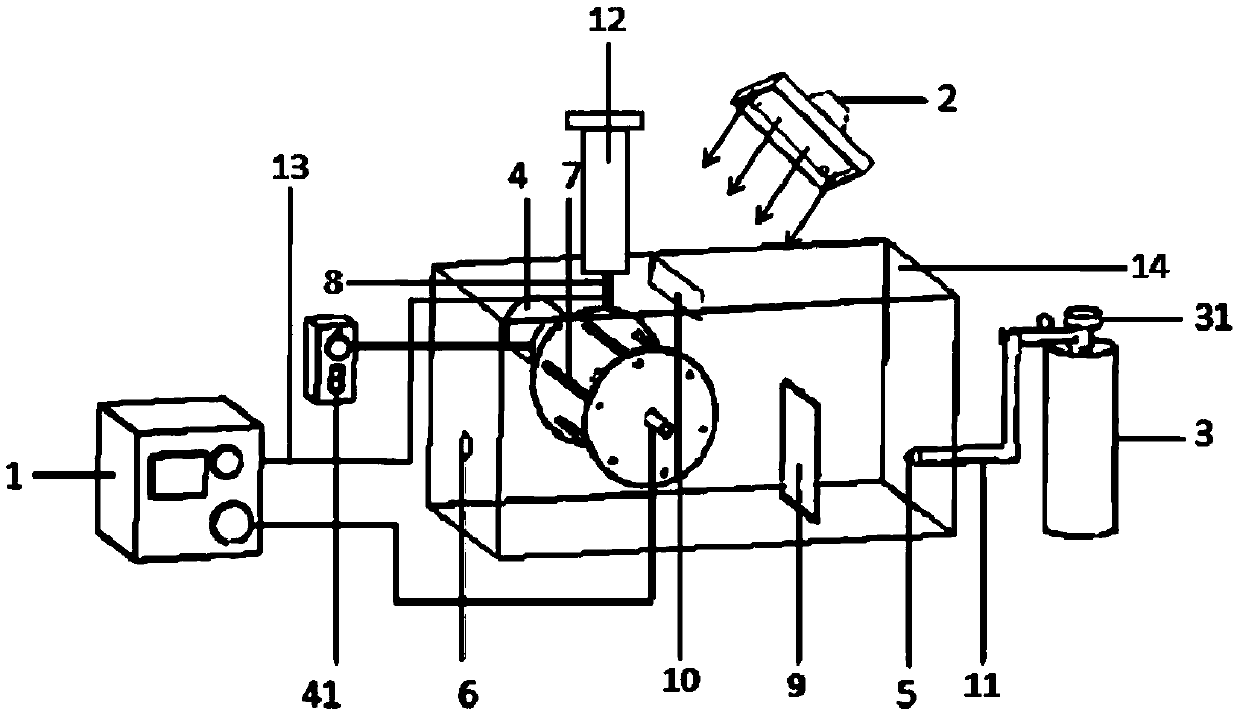

[0036] A method for preparing ordered polyurethane acrylate micro-nano fibers by large-scale solvent-free electrospinning, the method uses an electrospinning device such as figure 1 As shown, it includes a high-voltage power supply 1, a liquid storage mechanism 12, a spinning nozzle 8, an oxygen barrier mechanism, an ultraviolet light source 2 and a collector. The positive pole of the high-voltage power supply 1 is connected to the spinning nozzle 8, and the spinning nozzle 8 is connected to store the spinning precursor The liquid storage mechanism 12 of the liquid, the liquid storage mechanism 12 is a plastic syringe needle tube, the collector is connected to the negative pole of the high voltage power supply 1, the oxygen isolation mechanism includes an oxygen-free or oxygen-poor sealed box 14 inside, and the spinning nozzle 8 and the collecting pole are positioned in the sealed box 14, and the ultraviolet light source 2 is positioned outside the sealed box 14, and the ultrav...

Embodiment 2

[0041] A method for preparing ordered urethane acrylate micro-nano fibers by large-scale solvent-free electrospinning. The device used in this method is similar to that of Example 1, except that the gas cylinder 3 used in Example 2 is filled with carbon dioxide gas. The method includes the following steps:

[0042] (1) Configure the spinning precursor solution: add 0.5 gram of solid-state photoinitiator (184,1-hydroxy-cyclohexyl-phenyl ketone, Aldrich) in the Erlenmeyer flask, then add 9 grams of polyurethane acrylate (DR -U301, Changxing Chemical Industry Co., Ltd. (Taiwan)), carried out shading stirring with a magnetic stirrer, adopted 50 degree water bath heating, and stirred for 1 hour to make the solid-state photoinitiator and polyurethane acrylate mix and dissolve evenly; statically under natural light at room temperature Place it for 1 day to prepolymerize the polyurethane acrylate to a certain extent to obtain a precursor solution;

[0043] (2) Electrospinning micro-n...

Embodiment 3

[0045] A method for preparing ordered urethane acrylate micro-nano fibers by large-scale solvent-free electrospinning. The device used in this method is similar to that of Example 1, except that the gas cylinder 3 used in Example 2 is filled with helium. The method includes the following steps:

[0046] (1) Configure the spinning precursor solution: add 0.1 gram of liquid photoinitiator (photoinitiator1173, 2-hydroxyl-2-methyl-1-phenyl-1-acetone, Aldrich) in the Erlenmeyer flask, then add 2 grams Polyurethane acrylate (Sartomer704, Sartomer (Guangzhou) Chemical Co., Ltd.), carry out shading stirring with a magnetic stirrer, adopt 40 degree of water bath heating, stir for 1.5 hours, make photoinitiator and polyurethane acrylate mix and dissolve evenly, at room temperature Stand under natural light for 1.5 days, so that the polyurethane acrylate undergoes a certain degree of prepolymerization to obtain a precursor solution;

[0047] (2) Electrospinning micro-nanofibers: inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com