Material surface modification method by combination of plasma and chemical method

A plasma and surface modification technology, applied in textiles and papermaking, fiber treatment, physical treatment, etc., can solve the problem of low shear strength of materials, improve reactivity and efficiency, improve the degree of modification, and high-efficiency chemical treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

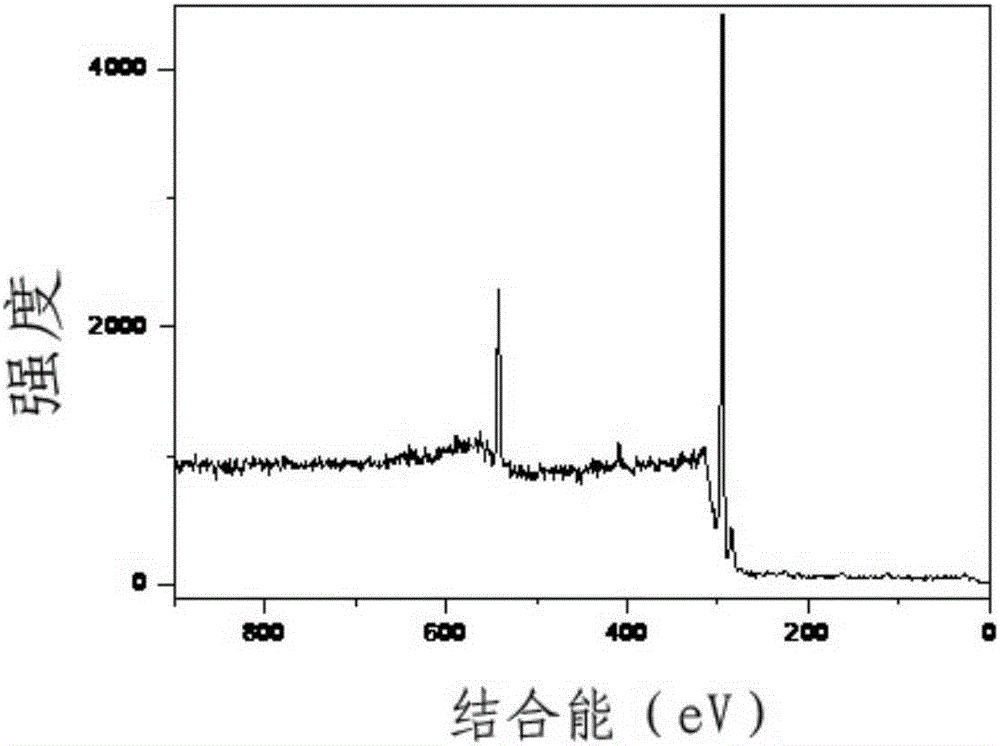

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: The method for surface modification of materials combined with plasma and chemical methods in this embodiment is carried out in the following steps:

[0017] 1. Plasma activation treatment: 1g~100g of material is placed in a plasma processor for treatment;

[0018] 2. Preparation of benzophenone hydrazone derivatives: Add 2g to 20g of benzophenone derivatives into a container, add 50mL to 1000mL of absolute ethanol and 1g to 50g of hydrazine hydrate with a mass fraction of 85% in turn, and stir Reflux reaction for 1d to 5d; then use the vacuum distillation method to concentrate the ethanol in the reaction solution, cool and crystallize the remaining reaction solution in an ice-water bath for 10min to 60min, filter the product under reduced pressure with a sand core funnel, and wash with distilled water for 3~ 5 times. After vacuum drying, the benzophenone hydrazone derivatives are obtained.

[0019] 3. Preparation of bisaryldiazomethane derivatives: Take...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is different from Embodiment 1 in that the material described in Step 1 is a polymer material or an inorganic non-metallic material. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the material described in step 1 is a carbon material. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com