Technology for extracting insoluble dietary fiber from bean dregs by enzyme process

A soluble dietary fiber and enzymatic extraction technology, applied in the field of food deep processing, can solve the problems of low purity of insoluble dietary fiber, inability to separate insoluble dietary fiber from soluble dietary fiber, etc., and achieve easy operation, easy operation and control, and reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

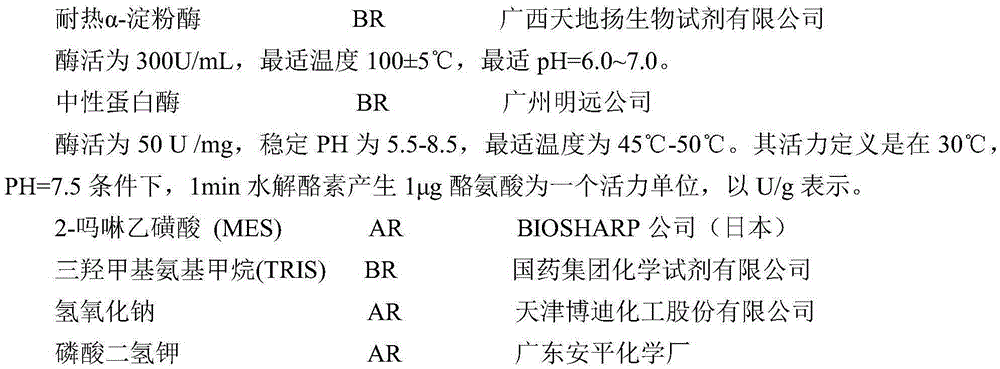

[0028] The reagents used in this embodiment are as follows:

[0029]

[0030] Utilize above-mentioned reagent to prepare solution as follows:

[0031] (1) 0.05mol / LMES-TRIS buffer:

[0032] Weigh 4.3021g MES and 2.6928g TRIS, dissolve them in 374mL of water, adjust the pH to 8.17 with 6mol / L sodium hydroxide (preparation temperature is 25°C, calculated by interpolation method), add water to dilute to 440mL.

[0033] (2) Neutral protease solution:

[0034] Use 0.05mol / LMES-TRIS buffer to prepare a 50mg / mL neutral protease solution, ready for immediate use, and the corresponding enzyme activity is 2500U / mL.

[0035] (3) Phosphate buffer solution of PH=6.8:

[0036] Take 250 mL of 0.2 mol / mL potassium dihydrogen phosphate, add 118 mL of 0.2 mol / mL sodium hydroxide solution, and dilute to 1000 mL with water.

[0037] The process of enzymatic extraction of insoluble dietary fiber in bean dregs of the present embodiment comprises the following steps:

[0038] (1) Dry the bea...

Embodiment 2

[0073] A process for enzymatically extracting insoluble dietary fiber from bean dregs, comprising the steps of:

[0074] (1) drying and pulverizing the bean dregs to obtain bean dregs powder;

[0075] (2) Add 5 ml of distilled water and 5 ml of phosphate buffer solution of pH6.5 to every gram of bean dregs powder to obtain bean dregs slurry;

[0076] (3) add neutral protease to bean dregs slurry and carry out enzymolysis for the first time, the add-on of neutral protease is step (1) described bean dregs powder: neutral protease=1g:0.7mg, obtain the first enzymatic hydrolysis bean dregs slurry ;

[0077] (4) Carrying out the first enzymatic deactivation treatment on the first enzymolysis bean dregs pulp to obtain the first deenzyme bean dregs pulp;

[0078] (5) adding heat-resistant α-amylase to the first enzyme-removing bean dregs slurry for the second enzymolysis, the amount of heat-resistant α-amylase is the bean dregs powder described in step (1): heat-resistant α-amylase...

Embodiment 3

[0085] A process for enzymatically extracting insoluble dietary fiber from bean dregs, comprising the steps of:

[0086] (1) drying and pulverizing the bean dregs to obtain bean dregs powder;

[0087] (2) Add 7 ml of distilled water and 7 ml of phosphate buffer solution of pH7.0 to every gram of okara powder to obtain okara powder;

[0088] (3) adding neutral protease to bean dregs slurry for the first enzymolysis, the addition of neutral protease is the bean dregs powder described in step (1): neutral protease=1g:1mg, to obtain the first enzymolysis bean dregs slurry;

[0089] (4) Carrying out the first enzymatic deactivation treatment on the first enzymolysis bean dregs pulp to obtain the first deenzyme bean dregs pulp;

[0090] (5) adding heat-resistant α-amylase to the first enzyme-removing bean dregs slurry for the second enzymolysis, the amount of heat-resistant α-amylase is the bean dregs powder described in step (1): heat-resistant α-amylase =1g:20 μl, obtain the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com