Preparation method of black phosphene nano sheet

A technology of nanosheets and black phosphorene, which is applied in the field of black phosphorene nanosheet preparation, can solve the problems of decreased electrical properties of two-dimensional materials, unsuitable for high-quality black phosphorene, limited peeling effect, etc., so as to avoid ultrasonic energy efficiency. Inadequate, Overcome Repeated Stripping Process, Wide Applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare a 0.01 mg / mL black phosphorus solution with 100 mL of dimethyl sulfoxide as an organic solvent.

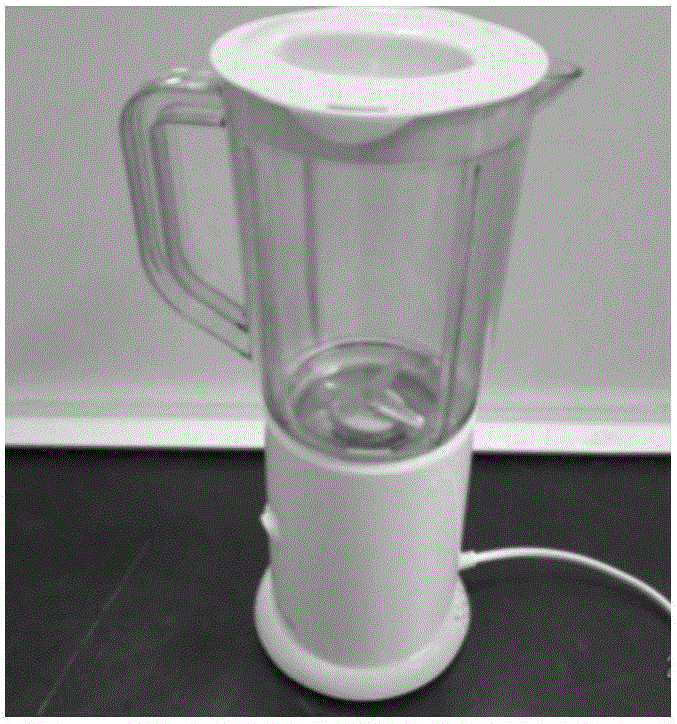

[0028] (2) Pour the above mixed dispersion into a cooking machine equipped with 2 cutter blades at the bottom, and then seal the machine cover with a packaging film to prevent the liquid from splashing out during the operation of the machine.

[0029] (3) Turn on the power supply, control the input voltage, operate the high-speed rotating cutter head at a speed of 3000rpm / min, and shear and peel off for a total of 0.1h. At this time, the bulk black phosphorus is peeled into black phosphorene nanosheets.

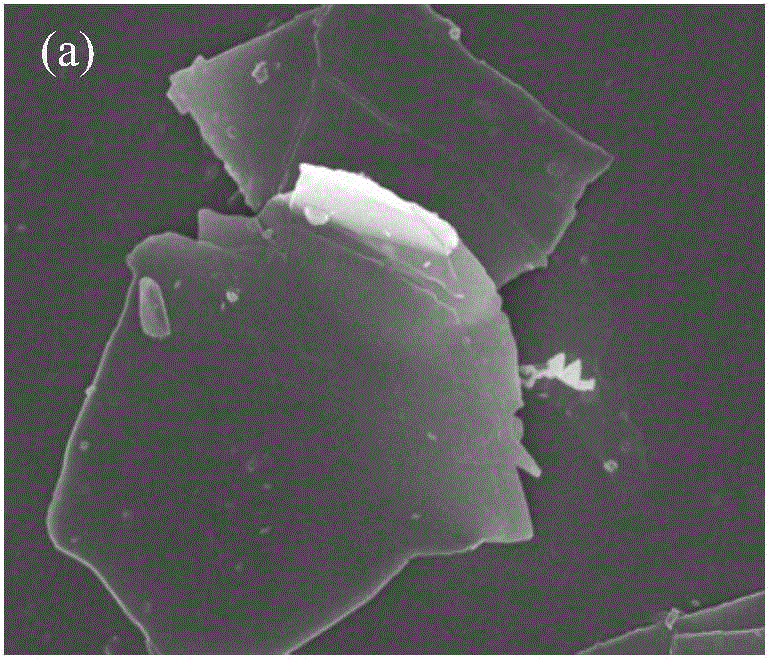

[0030] (4) Centrifuge the obtained black phosphorene nanosheet dispersion at 1000rpm / min and take the upper liquid, filter it with a polytetrafluoroethylene filter membrane to obtain black phosphorene nanosheets, and re-disperse after repeated washing with alcohol and isopropanol into isopropanol to obtain single-layer and few-layer black phosphorene nanosheet ...

Embodiment 2

[0032] (1) Use 250mL of N,N-dimethylformamide as an organic solvent to prepare a 0.1mg / mL black phosphorus solution.

[0033] (2) Pour the above-mentioned mixed dispersion into a soymilk machine equipped with 4 cutter blades at the bottom, and then seal the machine cover with a packaging film to prevent the liquid from splashing out during the operation of the machine.

[0034] (3) Turn on the power supply, control the input voltage, the operating speed of the high-speed rotary cutter head is 9000rpm / min, and the total shearing and peeling time is 0.5h. At this time, the bulk black phosphorus is peeled into black phosphorene nanosheets.

[0035] (4) Centrifuge the obtained black phosphorene nanosheet dispersion at 2000rpm / min, take the upper layer, filter it with a polytetrafluoroethylene filter membrane to obtain black phosphorene nanosheets, and re-disperse after repeated washing with alcohol and isopropanol into isopropanol to obtain single-layer and few-layer black phospho...

Embodiment 3

[0037] (1) Use 500 mL of N-methylpyrrolidone as an organic solvent to prepare a 1 mg / mL black phosphorus solution.

[0038] (2) Pour the above-mentioned mixed dispersion into a soymilk machine equipped with 4 cutter blades at the bottom, and then seal the machine cover with a packaging film to prevent the liquid from splashing out during the operation of the machine.

[0039](3) Turn on the power supply, control the input voltage, operate the high-speed rotating cutter head at a speed of 15,000 rpm / min, and shear and peel off for a total of 1 hour. At this time, the bulk black phosphorus is peeled into black phosphorene nanosheets.

[0040] (4) Centrifuge the obtained black phosphorene nanosheet dispersion at 3000rpm / min and take the upper liquid, filter it with a polytetrafluoroethylene filter membrane to obtain black phosphorene nanosheets, and re-disperse after repeated washing with alcohol and isopropanol into isopropanol to obtain single-layer and few-layer black phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com