Preparation method of graphene oxide thin film

A graphene film and graphite technology, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of limited shape and size of graphene films, serious stacking of graphene layers, and thick film preparation, and achieves convenient preparation process. The effect of fast, enhanced conductivity, good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

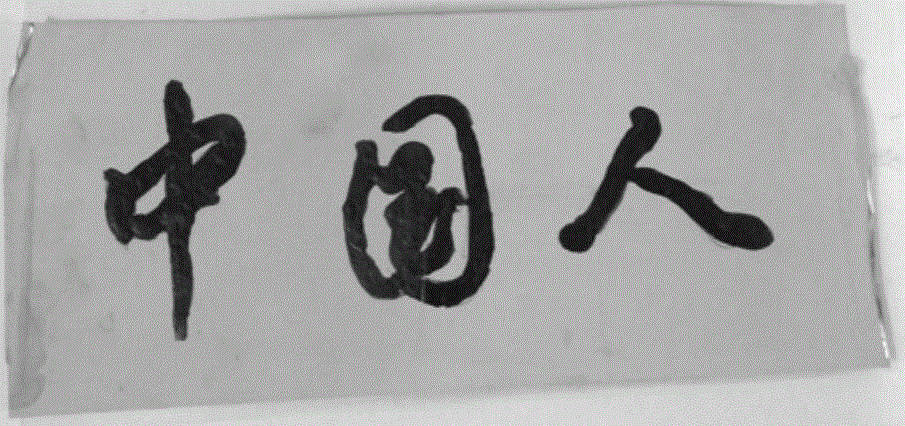

[0035] At room temperature, weigh 100 mg of graphite oxide and disperse it in 10 mL of ultrapure water. After sonicating in a water bath for 30 minutes, the cells are crushed for 5 minutes to obtain a uniformly dispersed graphite oxide aqueous solution. Dip the graphite oxide aqueous solution lightly with a wolf hair pen and write on the copper foil. "Chinese", the copper foil is fixed on the hot stage, the heating temperature of the hot stage is 45℃, each layer is heated for 2 minutes, the graphite oxide dispersion is almost dried on the surface of the copper foil, repeat 20 along the lines of the first writing After each brushing, heating and drying and micro-reduction are performed to avoid excessive stacking between graphene sheets, and a partially reduced graphene film with a thickness of about 2 μm and a low stacking degree is obtained. The prepared Chinese character shape graphene film digital picture such as figure 1 As shown, the XRD pattern is as Image 6 -a shown.

Embodiment 2

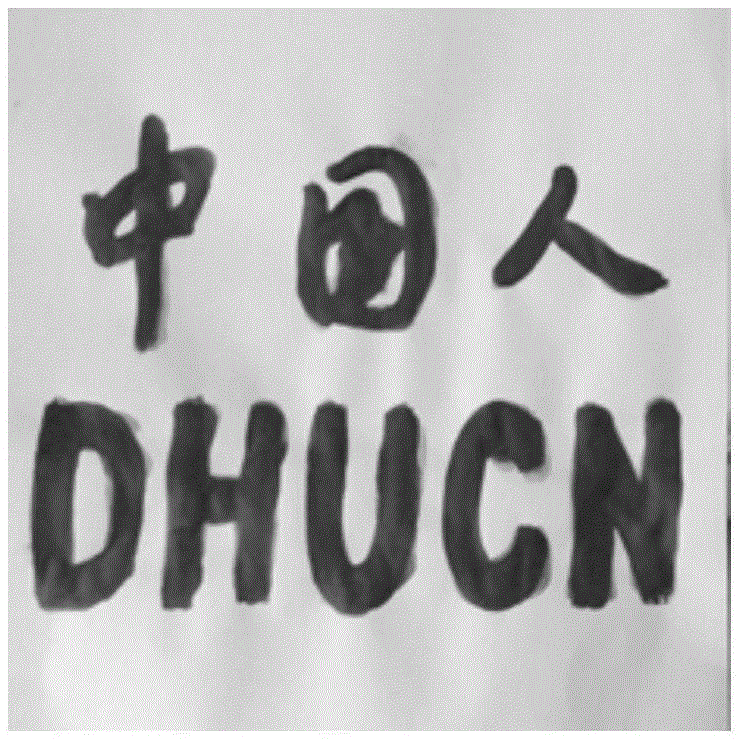

[0037] At room temperature, weigh 150 mg of graphite oxide and disperse it in 10 mL of ultrapure water. After sonicating in a water bath for 45 minutes, the cells are crushed for 5 minutes to obtain a uniformly dispersed graphite oxide aqueous solution. Dip the graphite oxide aqueous solution lightly with a wolf hair pen and write on the copper foil. "Chinese" and "DHUCN", the copper foil is fixed on the hot table, the heating temperature of the hot table is 30℃, and each layer is heated for 2 minutes. The graphite oxide dispersion is almost dried on the surface of the copper foil. Repeated 20 times, heating and drying and micro-reduction were performed after each brushing to avoid excessive stacking between graphene sheets, and a partially reduced graphene film with a thickness of about 1.5 μm and a low stacking degree was obtained. Digital pictures of graphene film in the shape of Chinese characters and letters prepared on plant fiber writing paper such as figure 2 Shown.

Embodiment 3

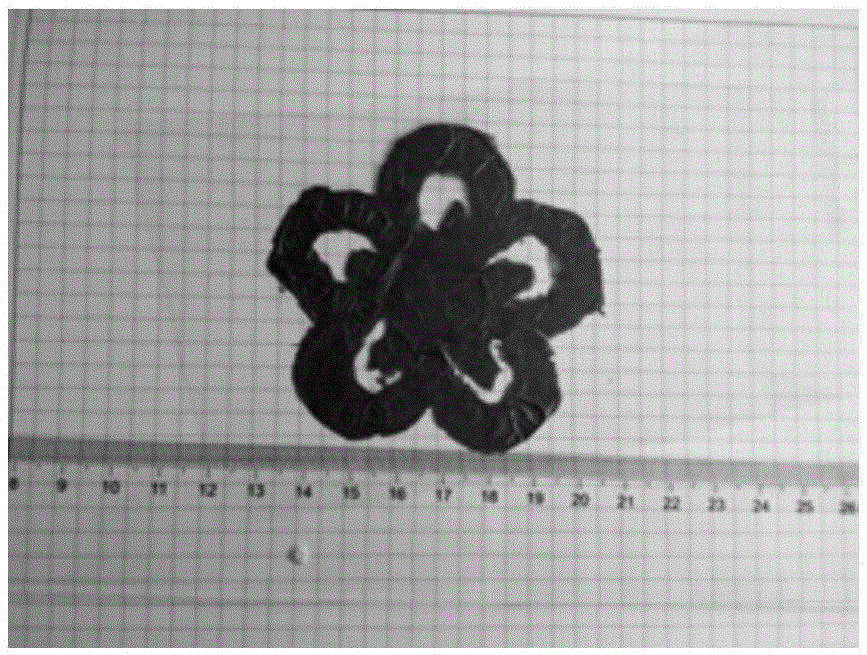

[0039] At room temperature, weigh 50 mg of graphite oxide and disperse it in 10 mL of ultrapure water. After 30 minutes of sonication in the water bath, the cells are crushed for 5 minutes to obtain a uniformly dispersed graphite oxide aqueous solution. Dip the graphite oxide aqueous solution lightly with a small letter writing brush and draw on the copper foil The copper foil is fixed on the hot table. The heating temperature of the hot table is 65℃, and each layer is heated for 2 minutes. The graphite oxide dispersion is almost dried on the surface of the copper foil. Repeated 50 times, heating and drying and micro-reduction were performed after each brushing to avoid excessive stacking between graphene sheets, and to obtain a partially reduced graphene film with a thickness of about 2.5 μm and a low stacking degree. Prepared on the surface of the cellulose filter membrane Shaped graphene film, the graphene-based cellulose filter membrane is removed with ethanol solution and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com