Composite material

A composite material and hydrotalcite technology, which is applied in the direction of aluminum compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of difficult control of size distribution, influence on adsorption performance, and agglomeration, so as to avoid large-scale agglomeration and broad application space , Improve the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 0.15mol / LCaCl according to the calcium-aluminum molar ratio of 5:1 2 and 0.15mol / LAlCl 3 Mix the solutions, adjust the pH value to 10 with 2mol / L NaOH solution at a reaction temperature of 40°C, and then add ethyl orthosilicate dropwise with 0.5mol / L NaOH solution to control the pH value to 11 during the whole dropping process, further stirring for 4-8h, centrifuging the sample, and freeze-drying. CaCl in this embodiment 2 and AlCl 3 Can be replaced by the corresponding nitrate.

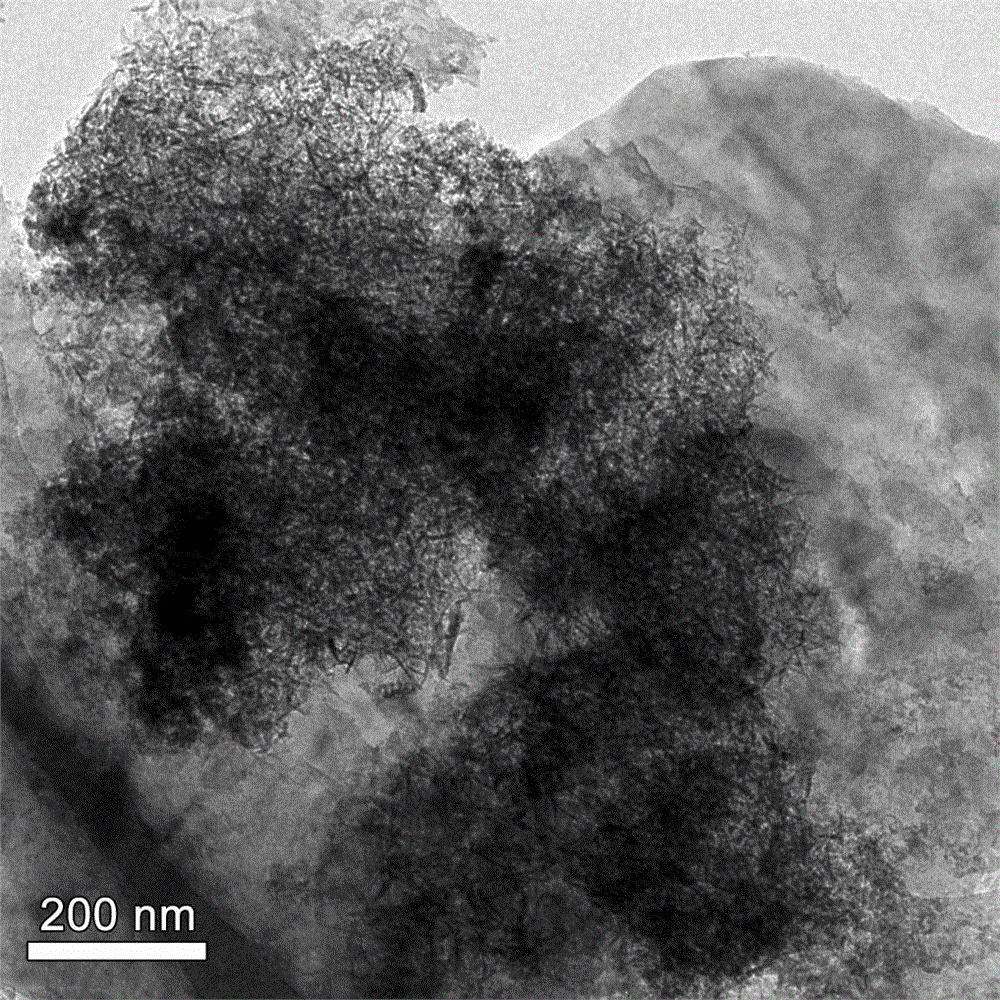

[0035] The composite material obtained in this experiment scheme is calcium silicate hydrate grown on the surface of hydrotalcite, in which the hydrotalcite part is composed of calcium and aluminum oxides, and the anions between the plates are chloride ions or nitrate ions.

[0036] Elemental analysis shows that: in the present embodiment, the molar ratio of relevant atoms in the composite material is Ca: Al: Si=4:1:0.65, and according to the calculation by comparison test, 82% of the...

Embodiment 2

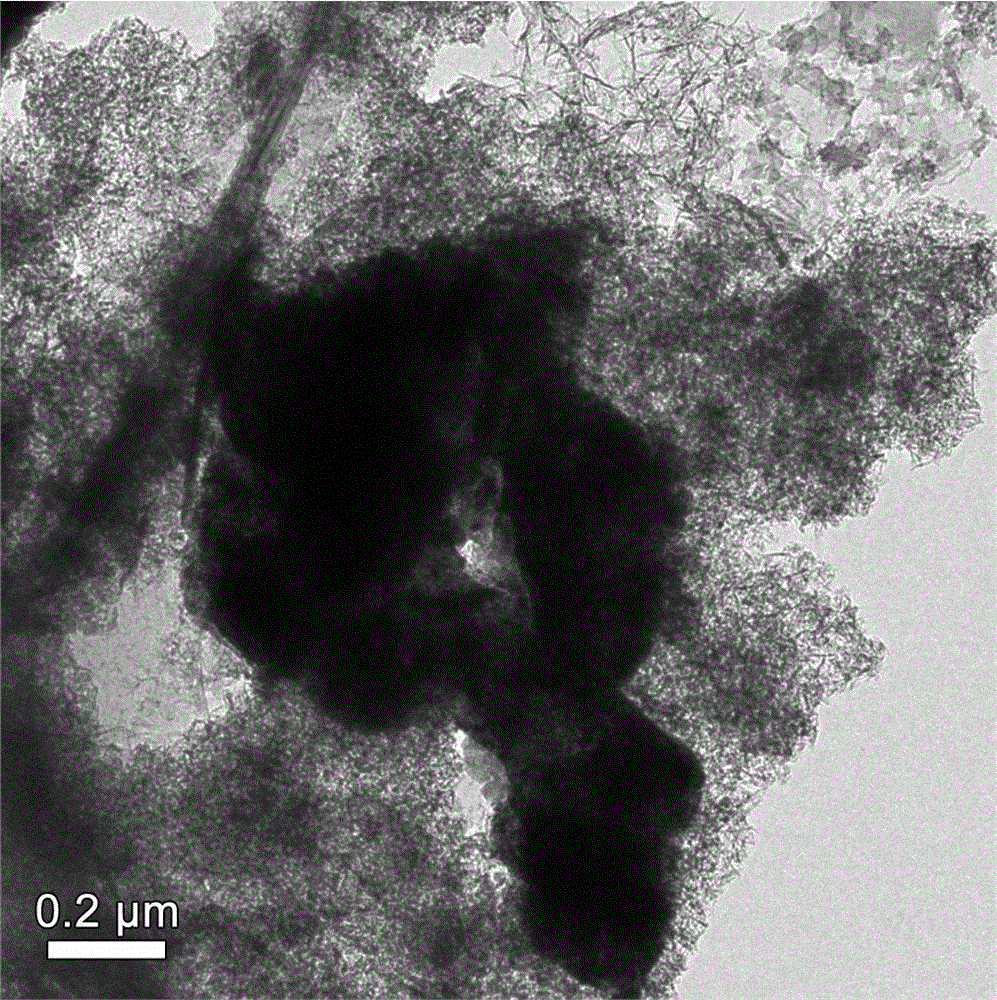

[0038] In this example, the hydrochloric acid extraction solution of oil shale ash residue was used as the aluminum source to prepare composite materials. The purpose of this example is to further verify the effect of the doping of various metal ions on the growth of calcium silicate hydrate on the surface of hydrotalcite. On the one hand, it can reduce the preparation cost of composite materials and realize the comprehensive utilization of waste; on the other hand, it can lay the foundation for further adjustment of the composition of hydrotalcite, and the hydrotalcite composed of multiple elements can make composite materials obtain a wider application space. The molar ratio of aluminum, magnesium, ferric iron and calcium ions in the extract is 33:0.78:3.8:1.2, and the molar ratio of divalent ions to trivalent ions is 4.5:1. CaCl 2 solution, the reaction temperature is 20°C, adjust the pH value to 10 with 2mol / L NaOH solution, then add dropwise sodium silicate solution acco...

Embodiment 3

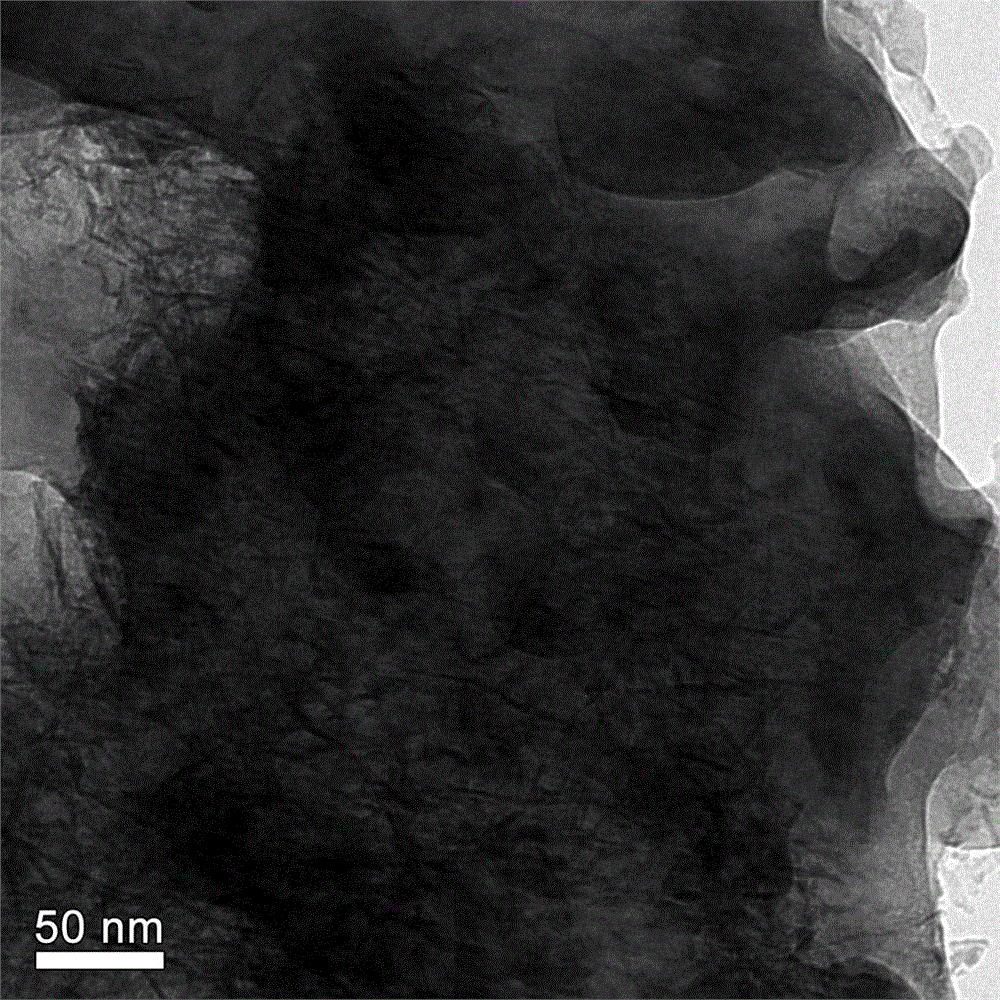

[0042] Add 0.15mol / LCaCl according to the calcium-aluminum molar ratio of 5:1 2 and 0.15mol / LAlCl 3 The solutions were mixed, and 0.05mol / L of Fe was added according to the Ca / Fe molar ratio of 60:1. 3 o 4 magnetic matrix suspension , The reaction temperature is 40°C, and the pH value is adjusted to 10 with 2mol / L NaOH solution. Then, under stirring conditions, add ethyl orthosilicate dropwise according to the ratio of calcium to silicon molar ratio of 5:1, and use 0.5mol / L NaOH solution controls the pH value to be 11 during the whole dropping process, and further stirs for 4-8h, and then magnetically separates the samples and freezes them to dry. CaCl in this embodiment 2 and AlCl 3 Can be replaced by the corresponding nitrate.

[0043] The composite material obtained in this experimental program is to grow calcium silicate hydrate on the surface of hydrotalcite, in which the hydrotalcite part is composed of calcium aluminum oxide layer, and the hydrotalcite layer is do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com