Aluminum oxide anti-static ceramic material and preparation method thereof

A technology of ceramic materials and alumina, which is applied in the field of ceramic materials and preparation, can solve the problems of poor mechanical properties of the glass phase, high cost, and reduced performance of the ceramic body, and achieve the effects of excellent antistatic performance, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

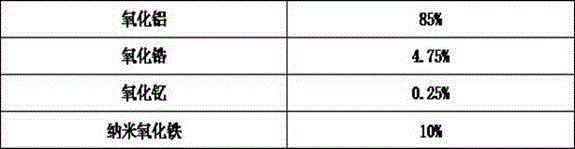

[0039] An antistatic alumina ceramic comprises the following components in mass fraction:

[0040]

[0041] Step one: the AlCl of 0.4mol / L 3 solution, ZrOCl 2 solution, Y (NO 3 ) 3 The solutions were converted into molar ratios according to the mass ratios in the table, weighed and mixed together, and stirred at a speed of 300 r / min for 1 hour to make them evenly mixed.

[0042] Step 2: Use a peristaltic pump to slowly drop ammonia water into the uniformly mixed solution, and at the same time, slowly stir the solution at a stirring speed of 30 r / min until the pH value of the solution is 9, and a mixed precipitate is formed. Wash the precipitate with water repeatedly until the absence of Cl- in the sol is tested with AgNO3 solution. Then use a centrifugal dehydrator to remove excess water at a speed of 4000r / min to obtain a mixed gel of aluminum hydroxide, zirconium hydroxide and yttrium hydroxide.

[0043] Step 3: Add the obtained mixed gel and nano-iron oxide into a p...

Embodiment 2

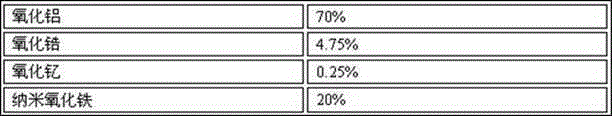

[0050] An antistatic alumina ceramic comprises the following components in mass fraction:

[0051]

[0052] Step one: the AlCl of 0.5mol / L 3 solution, ZrOCl 2 solution, Y (NO 3 ) 3 The solutions were converted into molar ratios according to the mass ratios in the table, weighed and mixed together, and stirred at a speed of 400 r / min for 2 hours to make them evenly mixed.

[0053] Step 2: Use a peristaltic pump to slowly drop ammonia water into the uniformly mixed solution, and at the same time, slowly stir the solution at a stirring speed of 20 r / min until the pH value of the solution is 10, and a mixed precipitate is formed. Wash the precipitate with water repeatedly until the absence of Cl- in the sol is tested with AgNO3 solution. Then use a centrifugal dehydrator to remove excess water at a speed of 3000r / min to obtain a mixed gel of aluminum hydroxide, zirconium hydroxide and yttrium hydroxide.

[0054] Step 3: Add the obtained mixed gel and nano-iron oxide into a...

Embodiment 3

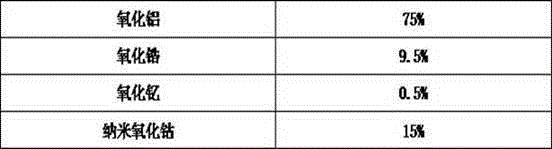

[0061] An antistatic alumina ceramic comprises the following components in mass fraction:

[0062]

[0063] Step one: the AlCl of 0.5mol / L 3 solution, ZrOCl 2 solution, Y (NO 3 ) 3 The solutions were converted into molar ratios according to the mass ratios in the table, weighed and mixed together, and stirred at a speed of 500 r / min for 3 hours to make them evenly mixed.

[0064] Step 2: Use a peristaltic pump to slowly drop ammonia water into the uniformly mixed solution, and at the same time, slowly stir the solution at a stirring speed of 40 r / min until the pH value of the solution is 10, and a mixed precipitate is formed. Wash the precipitate with water repeatedly until the absence of Cl- in the sol is tested with AgNO3 solution. Then use a centrifugal dehydrator to remove excess water at a speed of 3500r / min to obtain a mixed gel of aluminum hydroxide, zirconium hydroxide and yttrium hydroxide.

[0065] Step 3: Add the obtained mixed gel and nano-iron oxide into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com