Synergistic urea ammonium nitrogen fertilizer and preparation method of same

A technology of ammonium urea nitrogen fertilizer and synergist, which is applied in the direction of nitrogen fertilizer, fertilization equipment, fertilizer mixture, etc., can solve the problems of complex granulation process, high energy consumption, large investment, etc., and achieve cost reduction, low operating temperature, energy saving and reduction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] By weight components, take by weighing 18.2 parts of zinc sulfate, 27.3 parts of boric acid and 54.5 parts of polyaspartic acid, and mix to obtain a synergist;

[0033] According to the components by weight, weigh 10 parts of magnesium sulfate heptahydrate, 35 parts of urea, 50 parts of ammonium sulfate and 5 parts of synergist, mix for 3 minutes, the crystal water will gradually precipitate out, gradually integrate each component, and transport it through the conveyor belt Carry out crushing in the crushing equipment, pass through a 10-mesh sieve, granulate (the particle size is between 0.2-0.4mm), and dry at 80°C until the moisture content of the fertilizer is lower than 3% (mass ratio).

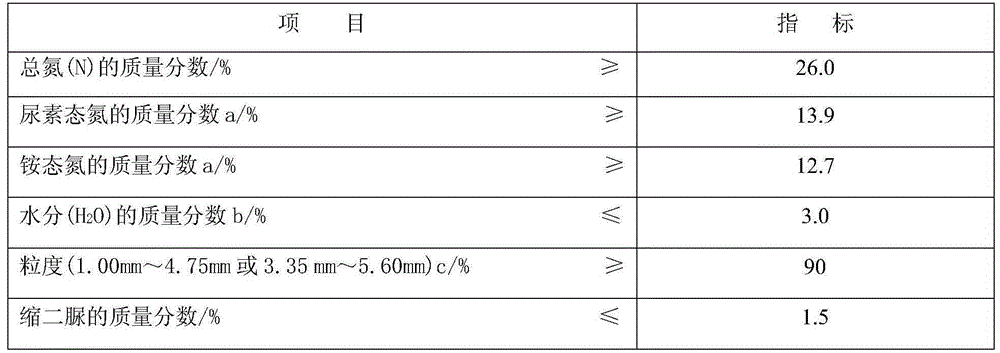

[0034] The test results are shown in Table 1.

[0035] The detection result of table 1 embodiment 1 gained product

[0036]

[0037]

Embodiment 2

[0039] By weight components, take by weighing 20 parts of zinc sulfate, 25 parts of boric acid and 55 parts of polyaspartic acid, and mix well to obtain a synergist;

[0040] According to the weight components, weigh 15 parts of magnesium sulfate heptahydrate, 30 parts of urea, 47 parts of ammonium sulfate and 8 parts of synergist, mix for 5 minutes, the crystal water will gradually separate out, and gradually integrate each component, and transport it through the conveyor belt Put it into a crushing equipment for crushing, pass through a 20-mesh sieve, granulate (the particle size is between 0.2-0.4mm), and dry at 40°C until the moisture content of the fertilizer is lower than 3% (mass ratio).

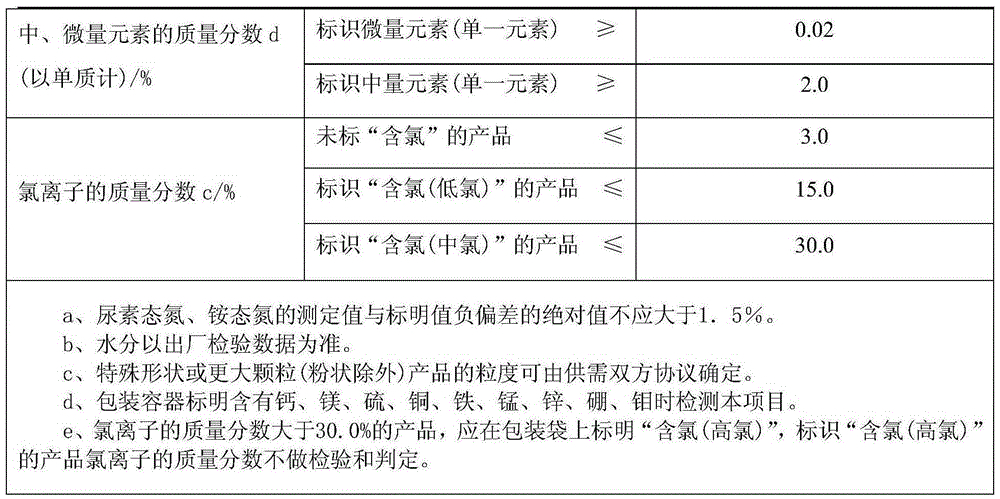

[0041] The test results are shown in Table 2.

[0042] The detection result of table 2 embodiment 2 gained products

[0043]

[0044]

Embodiment 3

[0046] By weight components, take 15 parts of zinc sulfate, 30 parts of boric acid and 55 parts of polyaspartic acid, and mix well to obtain a synergist;

[0047] According to the weight components, weigh 8 parts of magnesium sulfate heptahydrate, 40 parts of urea, 50 parts of ammonium sulfate and 2 parts of synergist, mix for 4 minutes, the crystal water will gradually precipitate out, and the components will be gradually integrated, and transported by the conveyor belt Put it into a crushing equipment for crushing, pass through a 20-mesh sieve, granulate (the particle size is between 0.2-0.4mm), and dry at 100°C until the moisture content of the fertilizer is lower than 3% (mass ratio).

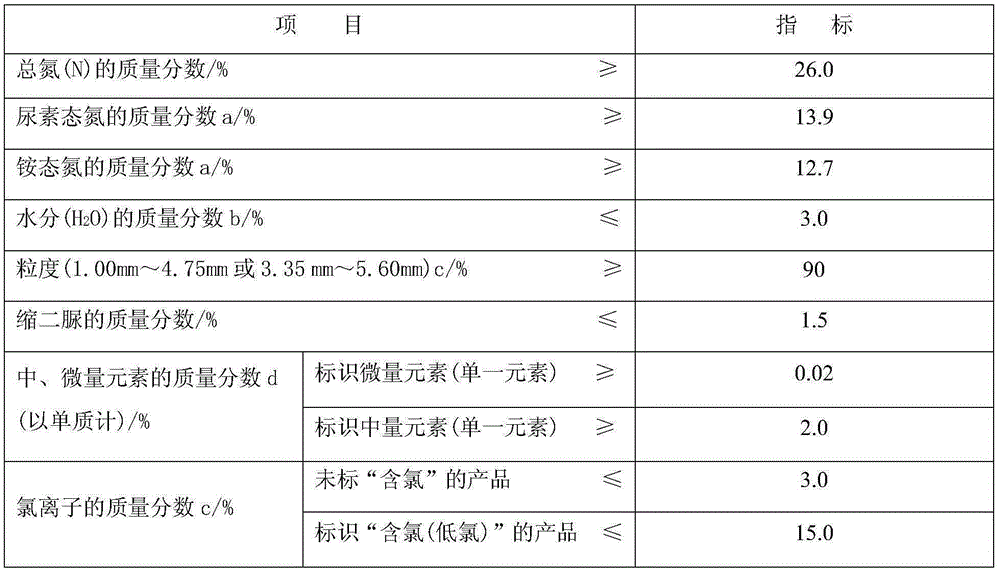

[0048] The test results are shown in Table 3.

[0049] The detection result of table 3 embodiment 3 gained products

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com