Macromolecular crosslinking agent based on oxidized cellulose, its gelatin film and preparation method

A technology of macromolecular cross-linking agent and oxidized cellulose, which is applied in the direction of climate change adaptation, sustainable manufacturing/processing, flexible coverings, etc., can solve the problems of low light transmittance and low transparency of gelatin film, and achieve mechanical properties Good, the effect of improving hydrophobicity and maintaining light-blocking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A synthetic method of a novel macromolecular cross-linking agent based on oxidized cellulose:

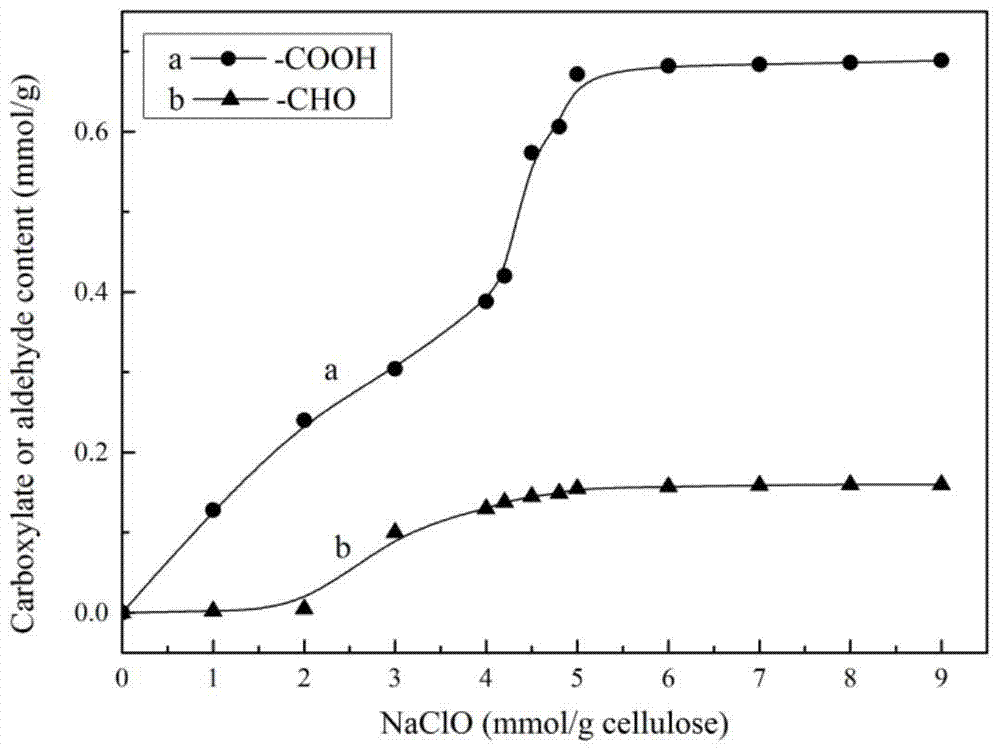

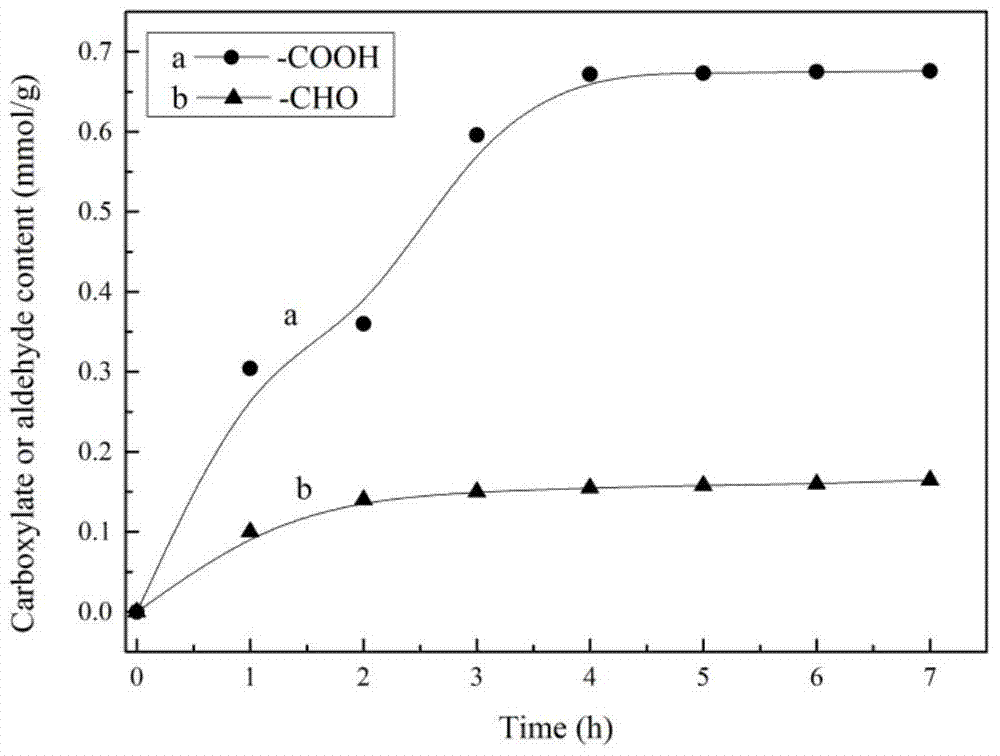

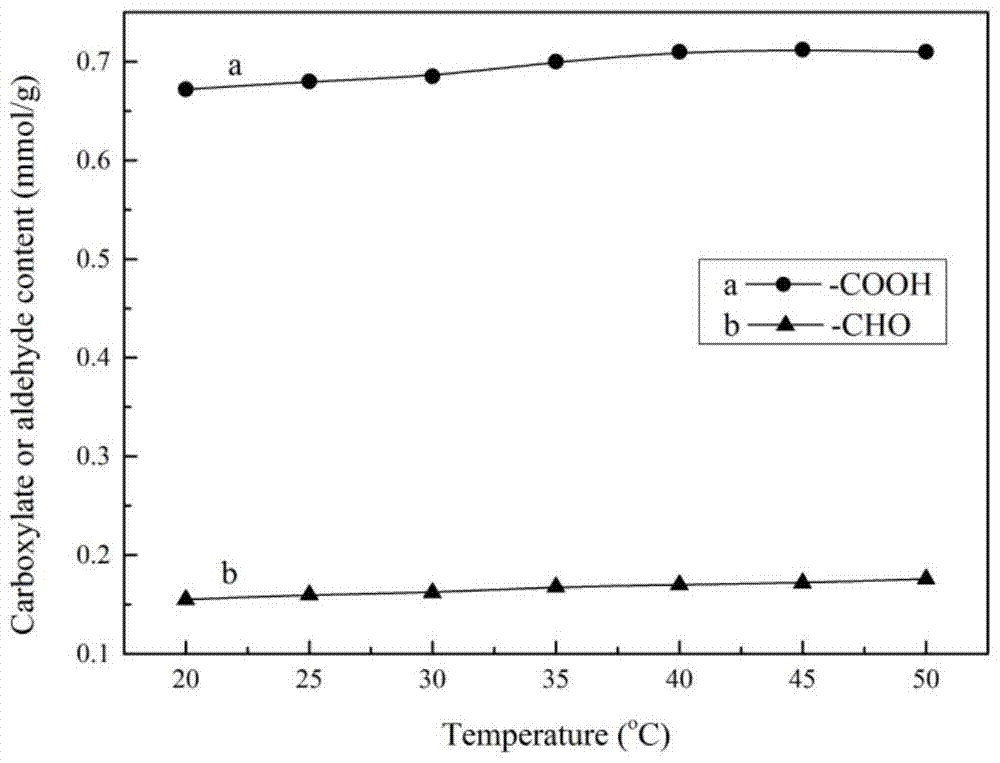

[0066] (1) Preparation of oxidized cellulose (TOMCC) and determination of carboxyl aldehyde group content:

[0067] Weigh the corresponding mass of microcrystalline cellulose (MCC), 2,2,6,6-tetramethylpiperidinyloxy radical (TEMPO) and NaBr in water (80ml / g MCC) in a mass ratio of 400:1:10. , 5mmol / g MCC's NaClO solution (5% available chlorine) was added dropwise during stirring, the pH was adjusted to 10.5, and the water bath was magnetically stirred for 4h at 20°C. Vacuum drying yielded a white powdery solid oxidized cellulose TOMCC. 10% (w / v) suspension of TOMCC in water with 0.9 g / g TOMCC in NaClO 2 Mixed secondary oxidation of TOMCC, 5M CH 3 The pH was adjusted to 4.2 with COOH, and oxidized for 48 h. After the oxidation, the precipitate was collected by centrifugation, washed with water three times, washed with ethanol once, and dried in vacuum at 40°C to obtain seco...

Embodiment 2

[0114] (1) Preparation of oxidized cellulose (TOMCC) and determination of carboxyl aldehyde group content:

[0115]Weigh the corresponding mass of microcrystalline cellulose (MCC), 2,2,6,6-tetramethylpiperidinyloxy radical (TEMPO) and NaBr in water (80ml / g MCC) in a mass ratio of 400:0.7:8 , 5mmol / g MCC NaClO solution (available chlorine 5%) was added dropwise during the stirring process, the pH was adjusted to 10, and the water bath was magnetically stirred for 2h at 20°C. Vacuum drying yielded a white powdery solid oxidized cellulose TOMCC. 10% (w / v) suspension of TOMCC in water with 0.8 g / g TOMCC in NaClO 2 Mixed secondary oxidation of TOMCC, 5M CH 3 The pH was adjusted to 4.5 with COOH, and oxidized for 40 h. After the oxidation, the precipitate was collected by centrifugation, washed with water three times, washed with ethanol once, and vacuum-dried at 40 °C to obtain secondary oxidized cellulose. The carboxyl group content of TOMCC and the aldehyde group content of se...

Embodiment 3

[0125] (1) Preparation of oxidized cellulose (TOMCC) and determination of carboxyl aldehyde group content:

[0126] Weigh the corresponding mass of microcrystalline cellulose (MCC), 2,2,6,6-tetramethylpiperidinyloxy radical (TEMPO) and NaBr in water (80ml / g MCC) in a mass ratio of 350:1:9 , 2mmol / g MCC NaClO solution (5% available chlorine) was added dropwise during stirring, pH was adjusted to 11, magnetic stirring was performed in a water bath at 20°C for 4h, after the reaction was completed, the precipitate was collected by centrifugation, washed with water three times, washed with ethanol once, at 40°C Vacuum drying yielded a white powdery solid oxidized cellulose TOMCC. 10% (w / v) suspension of TOMCC in water with 0.9 g / g TOMCC in NaClO 2 Mixed secondary oxidation of TOMCC, 5M CH 3 The pH was adjusted to 5 with COOH, and oxidized for 48 h. After the oxidation, the precipitate was collected by centrifugation, washed with water three times, washed with ethanol once, and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com