Method for supercritical CO2 extraction and purification of camellia seed oil

Camellia oleifera seed oil, supercritical technology, applied in chemical instruments and methods, organic chemistry, steroidal compounds, etc., can solve the problems of energy consumption, time consumption, etc., and achieve significant economic benefits, good quality, and high-quality preparation methods advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A supercritical CO 2 Method for extracting and purifying Camellia oleifera seed oil:

[0024] Step 1: Shelling. Camellia oleifera fruit peeling, using a camellia oleifera fruit peeling machine, peeling off the husk to obtain camellia oleifera seed kernels, the water content of the camellia oleifera seed kernels is 15%;

[0025] Step 2: Crush. Get 100kg camellia oleifera seed kernel and grind, the crushing fineness of camellia oleifera seed kernel powder is 20-50 order;

[0026] Step 3: alcoholysis. Add 1.0-1.5 parts by weight of alcohol solution to 100 kg of Camellia oleifera seed and nut powder, so that the volume percent concentration of the alcohol is 10-15%, the temperature of the mixed solution is 60-70° C., pH 6-8, and the time is 2-3 hours; Then heated to 80-90 ° C, reflux extraction for 2 hours, and then filtered; recovery of ethanol, alcoholysis. Ethanol is 75% ethanol.

[0027] Step 4: Hydrolysis. Mixing 100 kg of alcohol extract of camellia oleifera se...

Embodiment 2

[0033] Get 200kg of camellia oleifera seed kernels and pulverize, and the pulverization fineness of camellia oleifera seed kernel powder is 20-50 mesh. The water content of Camellia oleifera seed kernel is 15%.

[0034] The preparation method is the same as in Example 1. 30.5kg of tea saponin dry powder was obtained; 61.2kg of high-quality camellia oleifera oil was obtained.

Embodiment 3

[0036] Get 300kg of Camellia oleifera seed kernels and grind, and the crushing fineness of Camellia oleifera seed kernel powder is 20-50 mesh. The water content of Camellia oleifera seed kernel is 15%.

[0037] The preparation method is the same as in Example 1. 46.5kg of tea saponin dry powder was obtained; 91.6kg of high-quality camellia oleifera oil was obtained.

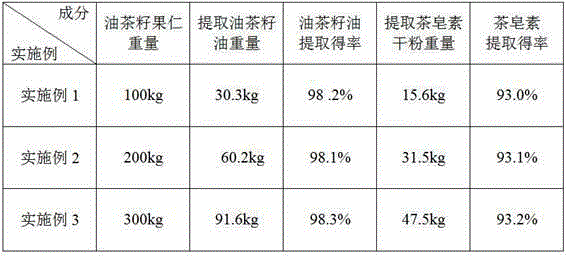

[0038] An example of the preparation method for extracting camellia oleifera seed oil and active substances from camellia oleifera seeds. The main component content analysis is shown in the following table:

[0039]

[0040] 1. The determination standard of Camellia oleifera seed oil is determined by GB11765-2003 Camellia oleifera seed oil standard

[0041] 2. The detection of tea saponin adopts the import and export industry standard SN / T1852-2006 Determination of saponin content in tea saponin for export

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com