Ruthenium palladium/carbon catalyst of cyclohexanecarboxylic acid synthesized through benzoic acid hydrogenation and preparation method and application thereof

A cyclohexylformic acid, carbon catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Expensive and other problems, to achieve the effect of simple production and recycling process, lower recycling cost and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

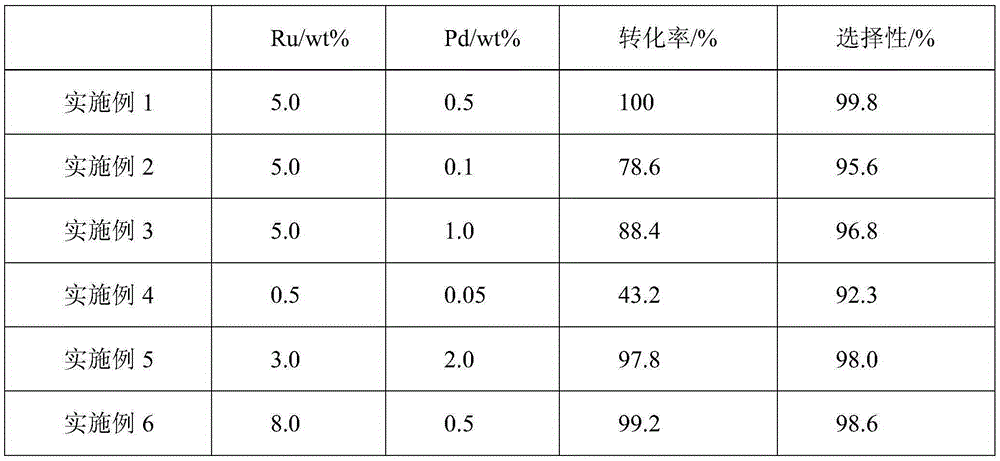

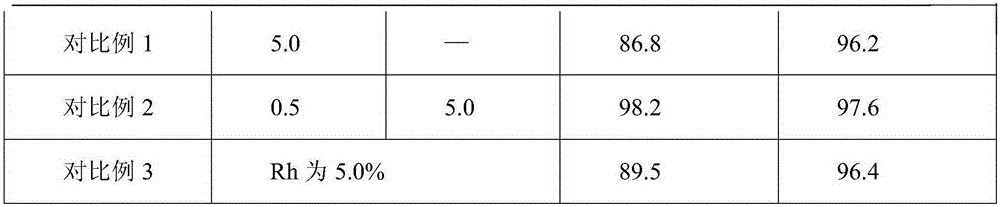

Examples

preparation example Construction

[0027] Preparation of ruthenium palladium / carbon catalyst:

[0028] Step 1, preparation of carbon material, mix potato powder, resorcinol, zinc chloride and water evenly, heat, then hydrolyze and polymerize at 95-100°C for 24-36h, take out the mixture and dry at 200-250°C after the reaction is completed 2 -8h, then carbonize at 500-700°C for 10-15h, then wash the carbonized solid product until it is free of chloride ions and then dry it;

[0029] Step 2, prepare soluble ruthenium salt and palladium salt solution, and then impregnate the carbon material with ruthenium salt and palladium salt solution respectively by vacuum equivalent impregnation method, impregnate for 2-10 hours, and then dry at 80°C-150°C for 2-8h Obtain ruthenium palladium / carbon catalyst precursor;

[0030] Step 3, adding NaOH solution to the ruthenium palladium / carbon catalyst precursor obtained in step 2, adjusting the pH to 9-13, precipitating for 0.5-6h and standing for 0.5-3h;

[0031] In step 4, for...

Embodiment 1

[0037] Preparation of ruthenium palladium / carbon catalyst:

[0038] Step 1, the preparation of carbon materials, mix 20g of potato powder, 5g of resorcinol, 65g of zinc chloride and water evenly and put them in an oil bath at 96°C for hydrolysis polymerization. After reacting for 30h, take out the mixture and put it in an oven at 220°C Dry in medium temperature for 8 hours, then transfer to a carbonization furnace for 12 hours at a constant temperature of 650°C, and finally wash the obtained solid product until there is no chloride ion, dry it for use, and the specific surface area of the prepared carbon carrier is 1460m 2 / g, the most probable pore diameter is 7.8nm;

[0039] Step 2, prepare 3 mol / L ruthenium chloride solution and 1.0 mol / L palladium chloride solution respectively according to 5.0% ruthenium load and 0.5% palladium load of active components;

[0040] Step 3, take 5g of carbon material, impregnate the prepared ruthenium and palladium solutions respectively ...

Embodiment 2

[0046] Preparation of ruthenium palladium / carbon catalyst:

[0047] Step 1, preparation of carbon material, mix 20g of potato flour, 5g of resorcinol, 65g of zinc chloride and water evenly, then place in an oil bath at 95°C for hydrolysis polymerization, and take out the mixture after reacting for 36h in an oven at 200°C Dry in medium temperature for 8 hours, then transfer to a carbonization furnace for 10 hours of constant temperature carbonization at 700°C, and finally wash the obtained solid product until there is no chloride ion, dry it for use, and the specific surface area of the prepared carbon carrier is 1580m 2 / g, the most probable pore diameter is 7.2nm;

[0048] Step 2, configure 3mol / L ruthenium acetate solution and 1.0mol / L palladium acetate solution respectively according to active component ruthenium loading 5.0% and palladium loading 0.1%;

[0049] Step 3, take 5g of carbon material, impregnate the prepared ruthenium and palladium solutions respectively by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com